Technology control method of production process of ferric trichloride and reaction tower

A production process and process control technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve the problems of excessive chlorine gas, affecting the safety and airtightness of production equipment, and hysteresis of terminal control, etc. problems, to achieve the effects of ensuring safety, improving raw material utilization rate and product one-time pass rate, ensuring thermal stability and pressure resistance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

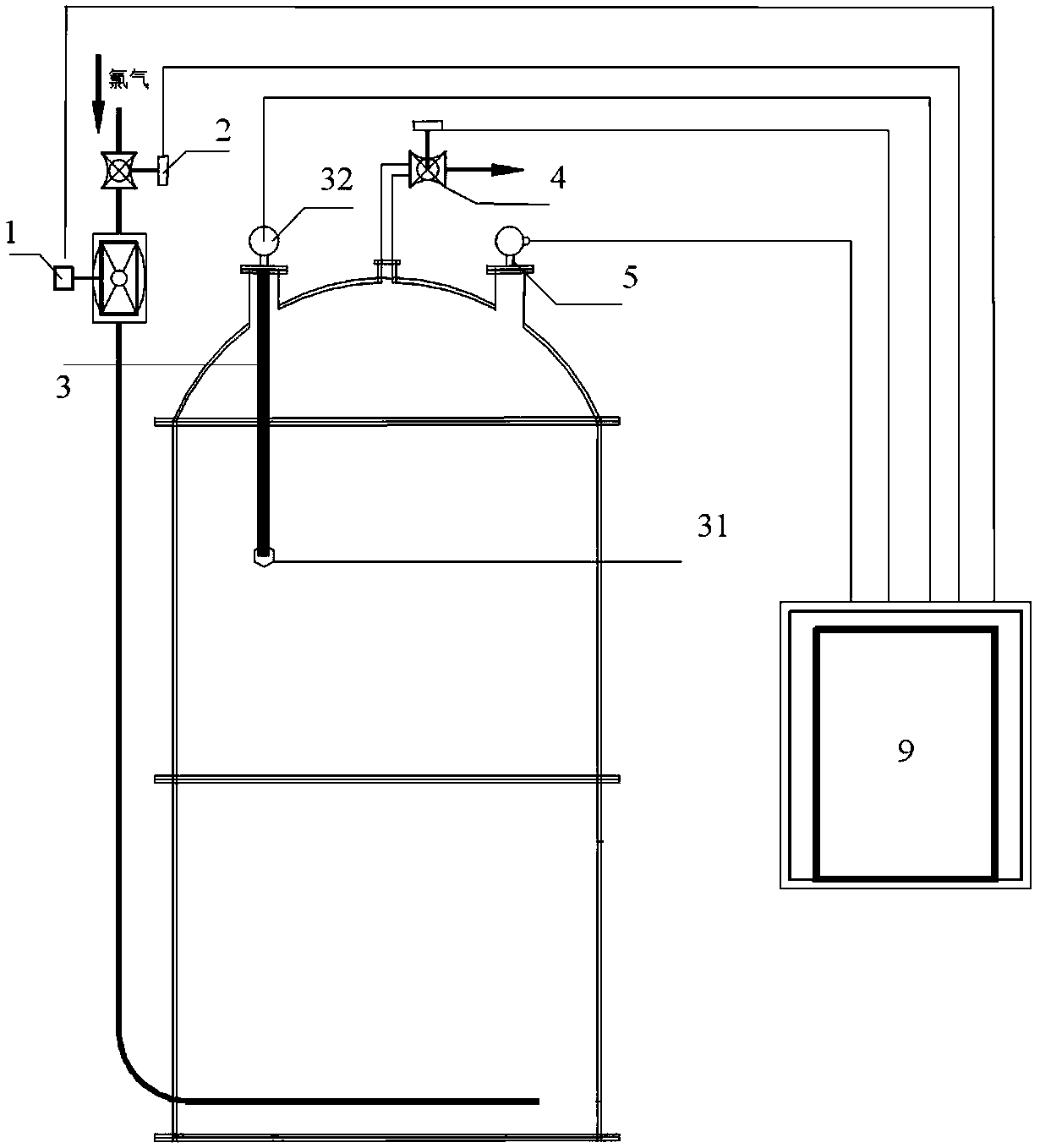

Image

Examples

Embodiment approach

[0046] Further, as another implementable manner, the following steps are also included:

[0047] Step S200, the opening degree of the chlorination controller reaches 100%, and the opening degree of the chlorination controller is adjusted to control the exhaust gas discharge flow value to be less than 5% of the intake flow value;

[0048] Step S300, after the opening degree of the chlorination controller reaches 100%, the flow value of the exhaust pipe is greater than the flow value of the intake pipe, the end point of the reaction is determined, and the chlorination controller is turned off.

[0049]The production process of ferric chloride is a chlorine gas absorption process. With the increase of the amount of chlorine added, ferrous chloride is gradually converted into ferric chloride, and the rate of chlorine gas absorption is gradually reduced. If you continue to add chlorine gas at a high speed, it will cause waste, but if you reduce it If the amount is too large, the pr...

Embodiment example 1

[0073] The production process control of the present invention includes two aspects - process control and end point control.

[0074] (1) Process control

[0075] Four reaction towers, add the ferrous chloride solution of 5000Kg concentration 32% in every tower, open reaction tower, chlorination controller is in 100% opening degree, along with the increase of chlorine addition, temperature and pressure raise gradually, according to The ratio of temperature, pressure, and intake gas flow rate determines whether the chlorination controller needs to be adjusted. When the temperature is higher than 80°C and / or the pressure is greater than 0.03MPa, one of the conditions is met, and the chlorination controller is adjusted as follows:

[0076] Every time the temperature increases by 1°C and / or the pressure increases by 0.002MPa, the opening degree of the chlorination controller is reduced by 10%, and if the pressure and temperature do not rise, the current opening degree is maintaine...

Embodiment example 2 10

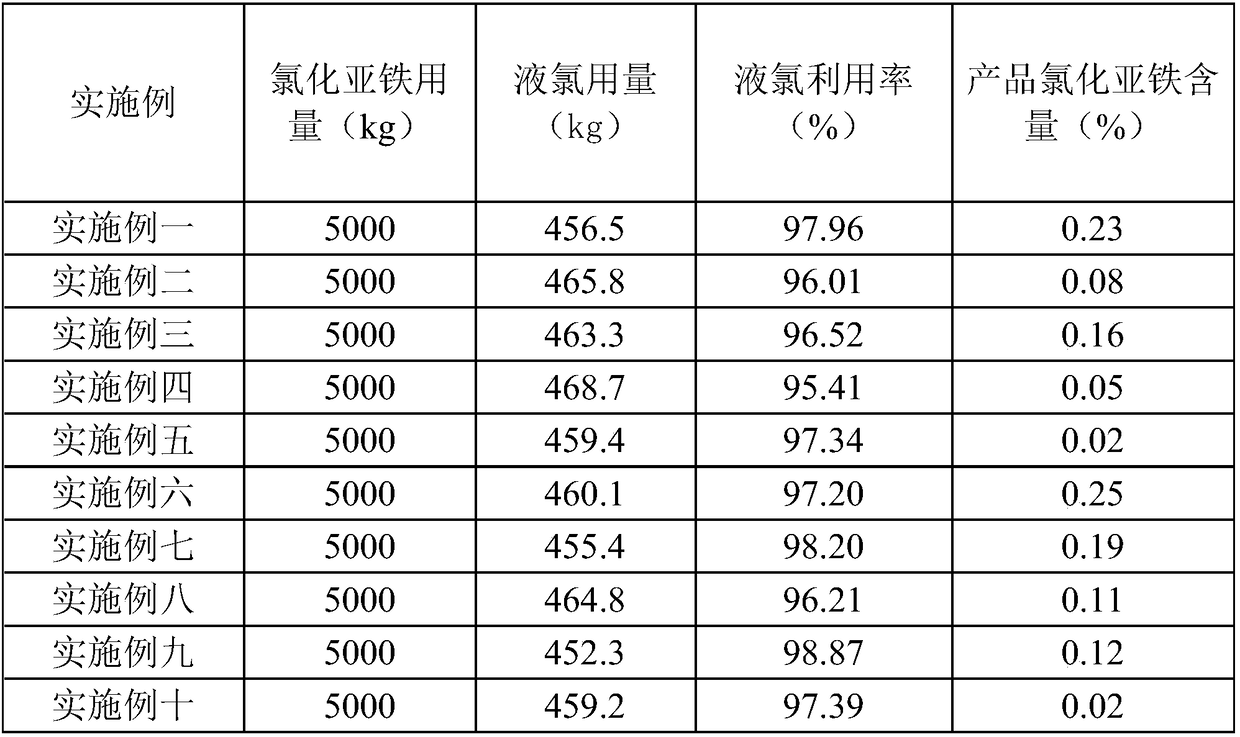

[0084] The following implementation cases 2 to 10 all adopt the method of implementation case 1, and other parameters and operation methods remain unchanged. The results of the implementation cases are shown in Table 1:

[0085] Table 1

[0086]

[0087] The utilization rate of chlorine in the invention reaches 95.41%-98.87%, which reduces the safety risk in the production process, and the content of ferrous chloride in the product ferric chloride is ≤0.25%, which is lower than 0.3% stipulated in the national standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com