A method for producing copper alloy wire by semi-solid continuous extrusion

A copper alloy and semi-solid technology, which is applied in the field of semi-solid continuous extrusion to produce copper alloy wire, can solve problems such as segregation of liquid copper easily oxidized, high requirements for molds, and large thermal conductivity, etc., to achieve excellent mechanical properties and improve mold quality. The effect of high life and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

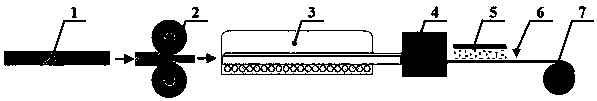

[0027] A method for producing copper alloy wire by semi-solid continuous extrusion, the forming process is as figure 1 As shown, the specific steps are as follows:

[0028] (1) The material in this example is ZCuSn10P1 copper alloy. The solidus temperature of the ZCuSn10P1 copper alloy was measured. The solidus temperature of the alloy was measured by differential scanning calorimetry (DSC) to be 876.1°C, and the liquidus temperature was 1024.2 ℃.

[0029] (2) Heat the rectangular ZCuSn10P1 copper alloy ingot to 550°C.

[0030] (3) Hot rolling the heated rectangular ingot, the hot rolling process is as follows: the rolling speed is 3m / min, the rolling pass is 2 times, and the cumulative deformation is 16%.

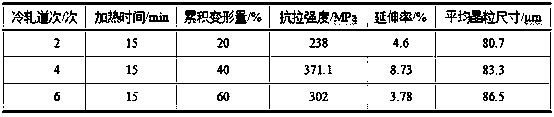

[0031] (4) Cool the hot-rolled rectangular ingot to room temperature, and then cold-roll it. The cold-rolling process is as follows: the rolling speed is 1m / min, and the rolling passes are 2 times, 4 times, and 6 times; the cumulative deformation 20%, 40%, and 60% respe...

Embodiment 2

[0037] A method for producing copper alloy wire by semi-solid continuous extrusion, the forming process is as figure 1 As shown, the specific steps are as follows:

[0038] (1) The material in this example is ZCuSn10P1 copper alloy. The solidus temperature of the ZCuSn10P1 copper alloy was measured. The solidus temperature of the alloy was measured by differential scanning calorimetry (DSC) to be 876.1°C, and the liquidus temperature was 1024.2 ℃.

[0039] (2) Heat the rectangular ZCuSn10P1 copper alloy ingot to 560°C.

[0040] (3) Hot rolling the heated rectangular ingot, the hot rolling process is as follows: the rolling speed is 2m / min, the rolling pass is 4 times, and the cumulative deformation is 18%.

[0041] (4) Cool the hot-rolled rectangular ingot to room temperature, and then cold-roll it. The cold-rolling process is as follows: the rolling speed is 2m / min, the rolling pass is 2 times, and the cumulative deformation is 20%.

[0042] (5) Heat the ingot after cold r...

Embodiment 3

[0046]A method for producing copper alloy wire by semi-solid continuous extrusion, the forming process is as figure 1 As shown, the specific steps are as follows:

[0047] (1) The material in this example is ZCuSn10P1 copper alloy. The solidus temperature of the ZCuSn10P1 copper alloy was measured. The solidus temperature of the alloy was measured by differential scanning calorimetry (DSC) to be 876.1°C, and the liquidus temperature was 1024.2 ℃.

[0048] (2) Heat the rectangular ZCuSn10P1 copper alloy ingot to 540°C.

[0049] (3) Hot rolling the heated rectangular ingot, the hot rolling process is as follows: the rolling speed is 4m / min, the rolling pass is 2 times, and the cumulative deformation is 12%.

[0050] (4) Cool the hot-rolled rectangular ingot to room temperature, and then cold-roll it. The cold-rolling process is as follows: the rolling speed is 3m / min, the rolling passes are 10 times, and the cumulative deformation is 60%.

[0051] (5) Heat the ingot after col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com