Composite polyethylene film containing chitosan and production method of composite polyethylene film

A polyethylene film and chitosan technology, which is applied in the field of packaging materials, can solve the problems that the composite structure packaging cannot be well realized, the composite film cannot play a bacteriostatic effect, and the contents are rotted, etc. The effect of improving elongation, good antibacterial performance and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

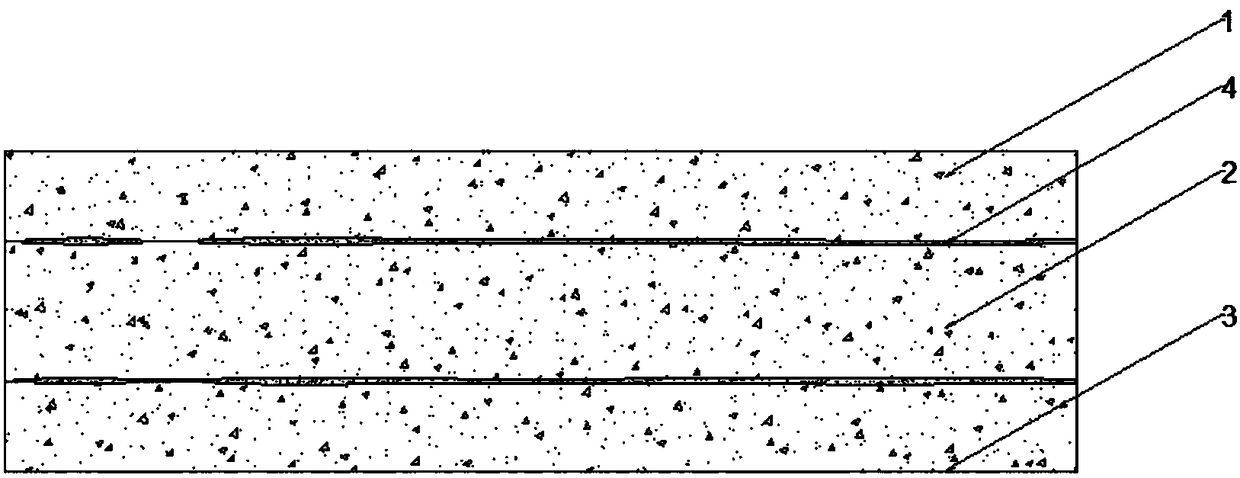

Image

Examples

Embodiment 1

[0028] (1) Preparation of corona layer: add linear low density polyethylene with a mass fraction of 49%, 50% low density polyethylene, and 1% fluorine-containing resin into a mixer and stir evenly, and proceed at a melting temperature of 165~180°C Blending and extruding to form a corona layer molten material, and then the corona layer molten material enters the co-extrusion die head to co-extrude with the middle layer molten material and the inner layer molten material from other extruders;

[0029](2) Preparation of the middle layer: Add 49% linear low-density polyethylene, 50% low-density polyethylene, and 1% silicone into a mixer and stir evenly, and blend at a melting temperature of 165~180°C Extrude to form the middle layer molten material, which then enters the co-extrusion die and co-extrudes with the corona layer molten material and inner layer molten material from other extruders;

[0030] (3) Preparation of inner layer: 26% metallocene linear low density polyethylene...

Embodiment 2

[0033] (1) Preparation of corona layer: add linear low density polyethylene with a mass fraction of 49%, 50% low density polyethylene, and 1% fluorine-containing resin into a mixer and stir evenly, and proceed at a melting temperature of 165~180°C Blending and extruding to form a corona layer molten material, and then the corona layer molten material enters the co-extrusion die head to co-extrude with the middle layer molten material and the inner layer molten material from other extruders;

[0034] (2) Preparation of the middle layer: add 80% ethylene-butylene copolymerized linear low-density polyethylene, 19% low-density polyethylene, 0.5% silicone, and 0.5% fluorine-containing resin into a mixer and stir evenly, and Blending and extrusion is carried out at a melting temperature of 165~180°C to form a middle layer molten material, and then the middle layer molten material enters the co-extrusion die head together with the corona layer molten material and the inner layer molte...

Embodiment 3

[0039] (1) Preparation of corona layer: add linear low density polyethylene with a mass fraction of 49%, 50% low density polyethylene, and 1% fluorine-containing resin into a mixer and stir evenly, and proceed at a melting temperature of 165~180°C Blending and extruding to form a corona layer molten material, and then the corona layer molten material enters the co-extrusion die head to co-extrude with the middle layer molten material and the inner layer molten material from other extruders;

[0040] (2) Preparation of the middle layer: add 80% ethylene-butylene copolymerized linear low-density polyethylene, 19% low-density polyethylene, 0.5% silicone, and 0.5% fluorine-containing resin into a mixer and stir evenly, and Blending and extrusion is carried out at a melting temperature of 165~180°C to form a middle layer molten material, and then the middle layer molten material enters the co-extrusion die head together with the corona layer molten material and the inner layer molte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com