Method and device for removing fluorides in wastewater step by step

A technology of fluoride and waste water, which is applied in descaling and water softening, chemical instruments and methods, water pollutants, etc. It can solve the problems of difficulty in reaching water standards, difficulty in sludge sedimentation, and low efficiency, and reduce the dosage of chemicals , low operating cost, and the effect of improving the sludge structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Fluorine content test after primary treatment and secondary advanced treatment

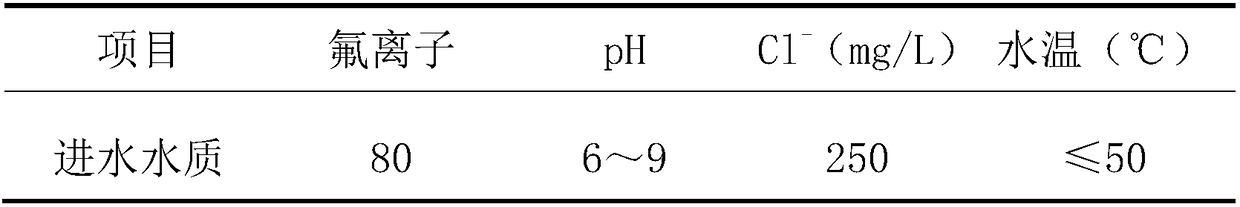

[0034] The coal gasification water of a sewage treatment plant in Shanxi is 1920 tons per day, and the water intake indicators are shown in Table 1:

[0035] Table 1 Water quality of coal gasification water

[0036]

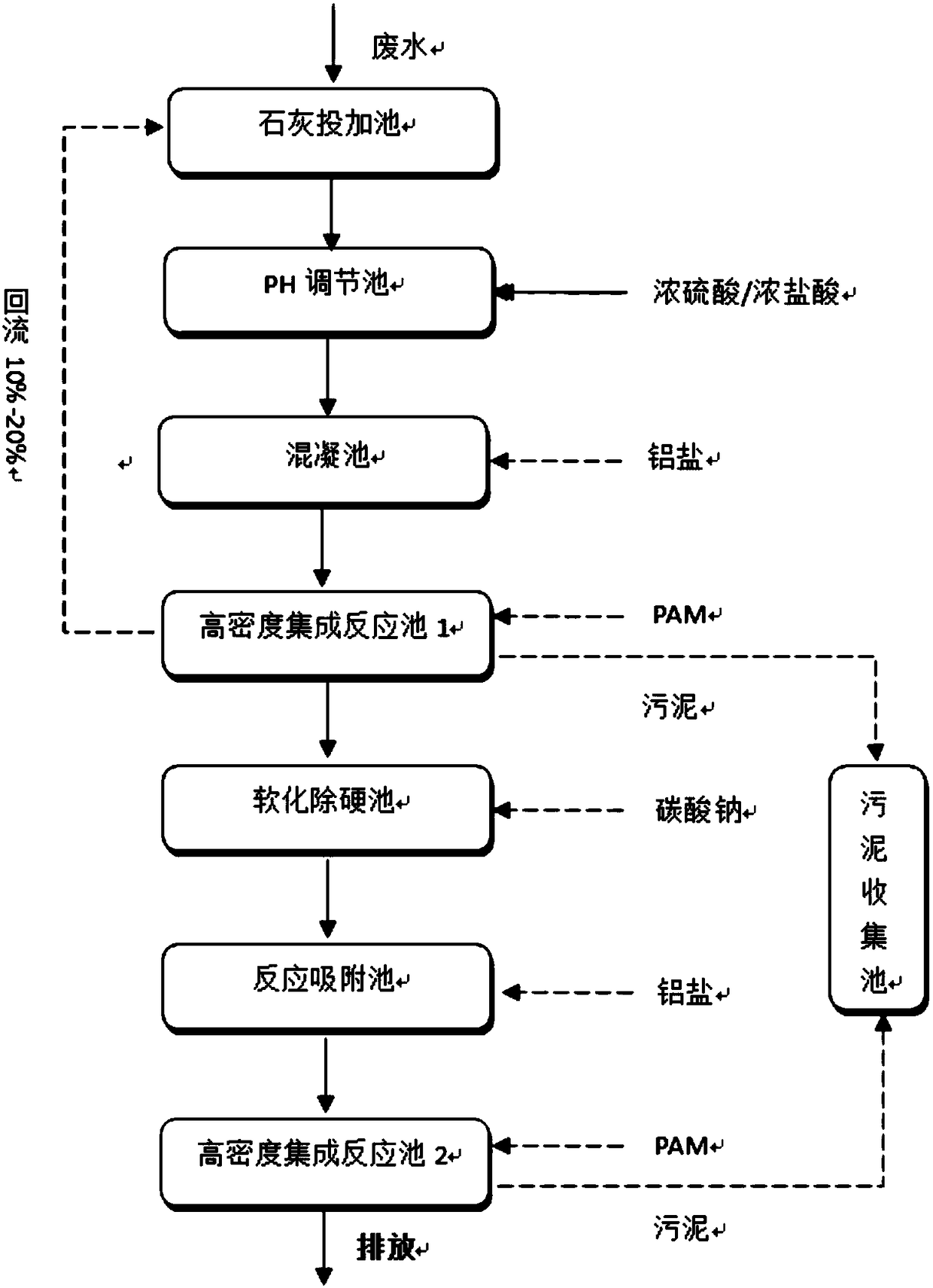

[0037] Sewage is divided into two parts: primary treatment and secondary advanced treatment.

[0038] The primary treatment is as follows: lime dosing tank, PH adjustment tank, coagulation tank, high-density integrated reaction tank 1.

[0039] The wastewater first passes through the lime dosing tank, and the excess lime is added to react with the fluoride ions in the wastewater to form CaF 2 precipitation.

[0040] The specific equation involved is: Ca 2+ +2F - →CaF 2 ↓

[0041] The PH adjustment tank uses concentrated sulfuric acid to adjust the effluent from the lime dosing tank, and the pH value is adjusted to 8.4. With the formation of calcium sulfate...

Embodiment 2

[0052] Embodiment 2: comparison of reflux in primary treatment

[0053] For coal gasification water of a sewage treatment plant in Xi'an, the influent indicators are shown in Table 3:

[0054] Table 3 Influent water quality of coal gasification water

[0055]

[0056] The dosage of lime is the same, both are 560mg / l, and the fluorine content of the primary effluent is shown in Table 4 when the reflux ratio is different:

[0057] Fluorine content under different reflux ratios in table 4

[0058]

[0059] When the reflux is not set, the amount of lime required to achieve the reflux value in the above table is shown in Table 5:

[0060] Lime consumption under different reflux ratios in table 5

[0061]

[0062] Conclusion: 1. The comparison shows that the effect of water discharge without backflow is obviously worse than that with backflow;

[0063] 2. When the reflux ratio is above 10%, the effluent effect basically does not change much. When it exceeds 25%, the flu...

Embodiment 3

[0065] Example 3: Contrast with or without softening and hard removal in the secondary advanced treatment

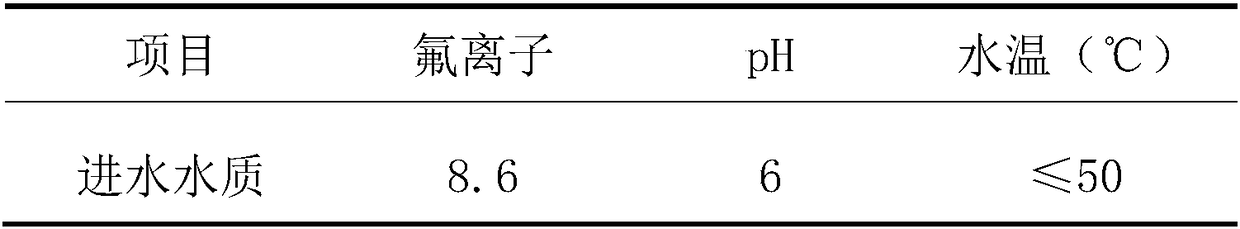

[0066] The influent indicators of coal gasification water in a sewage treatment plant in Guangxi are shown in Table 6:

[0067] Table 6 Influent water quality of coal gasification water

[0068]

[0069] The fluorine content of the water in and out of the softening and dehardening pool is shown in Table 7:

[0070] Table 7 Fluorine content of water quality in and out of water

[0071]

[0072] Conclusion: During the hard removal process of the softening pool, the calcium carbonate precipitate formed and the CaF formed 2 , Complex complexes are adsorbed together, which enhances the effect of fluorine removal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com