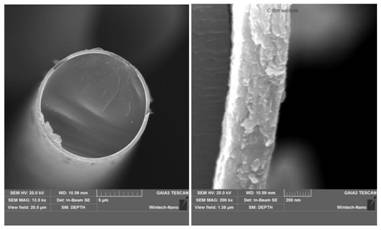

A device and method for depositing an interface layer on a fiber surface

A fiber surface and interface layer technology, applied in fiber treatment, coating, metal material coating process, etc., can solve problems such as low efficiency, too thin interface layer, difficult to control diffusion, etc., achieve high utilization rate, avoid damage, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The continuous SiC fiber was placed in a muffle furnace at 400°C for 30 minutes under air condition; that is, the pretreated SiC fiber bundle after degumming was obtained.

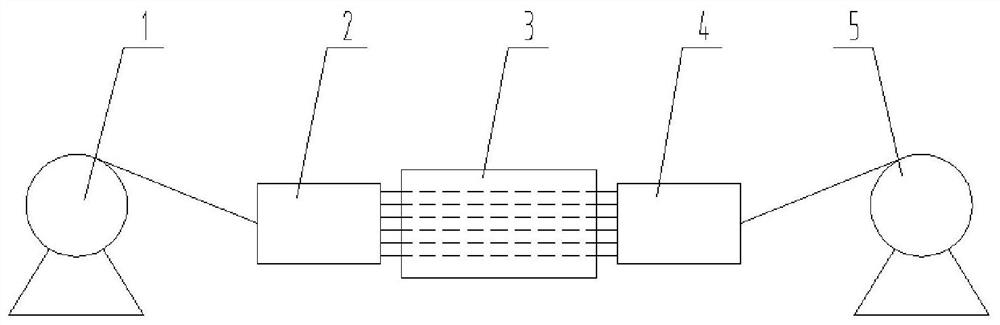

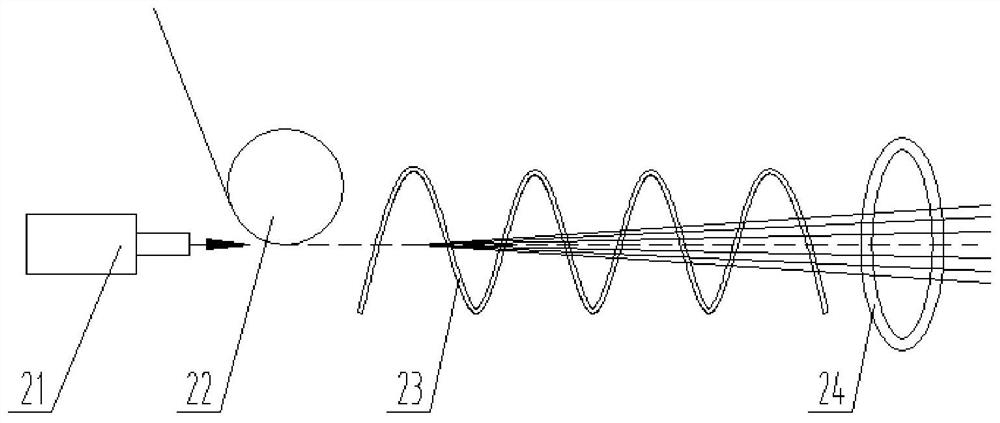

[0083] The SiC fiber bundle is released from the wire-feeding device and steered by the steering wheel between the electron emission gun and the magnetic induction coil. The steered SiC fiber bundle and the electron beam emitted by the electron emission gun form an angle of α, and the 0 °≤α≤5°, after the SiC fiber bundle enters the magnetic induction coil, the electron beam emitted by the electron gun makes the SiC fiber polarized with negative static electricity. The static electrostatic constriction ring O enters the magnetron sputtering device. Since the SiC fiber bundle is subjected to the Lorentz force and electrostatic repulsion in the magnetic induction coil and the electrostatic constricting ring, the fiber bundle will not be excessively dispersed, which not only enables the fiber to advance...

Embodiment 2

[0095] The continuous SiC fiber is kept in the air environment of a muffle furnace at a temperature of 500° C. for 15 minutes; that is, a pretreated SiC fiber bundle is obtained.

[0096] The SiC fiber bundle is released from the wire-feeding device and steered by the steering wheel between the electron emission gun and the magnetic induction coil. The steered SiC fiber bundle and the electron beam emitted by the electron emission gun form an angle of α, and the 0 °≤α≤5°, after the SiC fiber bundle enters the magnetic induction coil, the electron beam emitted by the electron gun makes the SiC fiber polarized with negative static electricity. The static electrostatic constriction ring O enters the magnetron sputtering device. Since the SiC fiber bundle is subjected to the Lorentz force and electrostatic repulsion in the magnetic induction coil and the electrostatic constricting ring, the fiber bundle will not be excessively dispersed, which not only enables the fiber to advance...

Embodiment 3

[0108]The continuous SiC fiber is kept in the air condition of a muffle furnace at a temperature of 600° C. for 10 minutes; that is, a pretreated SiC fiber bundle is obtained.

[0109] The SiC fiber bundle is released from the wire-feeding device and steered by the steering wheel between the electron emission gun and the magnetic induction coil. The steered SiC fiber bundle and the electron beam emitted by the electron emission gun form an angle of α, and the 0 °≤α≤5°, after the SiC fiber bundle enters the magnetic induction coil, the electron beam emitted by the electron gun makes the SiC fiber polarized with negative static electricity. The static electrostatic constriction ring O enters the magnetron sputtering device. Since the SiC fiber bundle is subjected to the Lorentz force and electrostatic repulsion in the magnetic induction coil and the electrostatic constricting ring, the fiber bundle will not be excessively dispersed, which not only enables the fiber to advance al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com