Nano starch filtrate reducer for drilling fluid and preparation method thereof

A technology of nano-starch and filtrate reducing agent, applied in chemical instruments and methods, drilling composition, etc., can solve the problem of the large influence of drilling fluid system viscosity, less research on drilling fluid application, and poor temperature resistance of treatment agents, etc. problems, to achieve the effect of reducing drilling fluid filtration, optimizing process methods, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

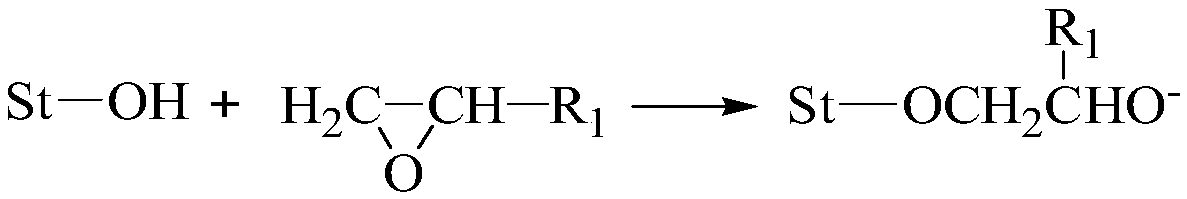

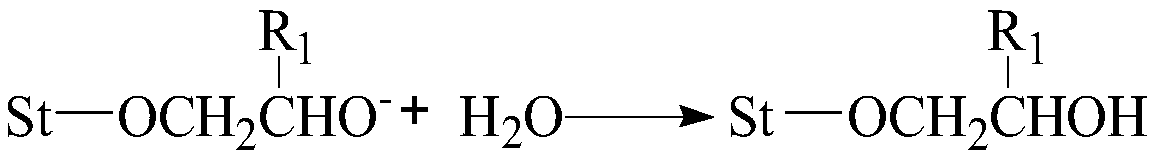

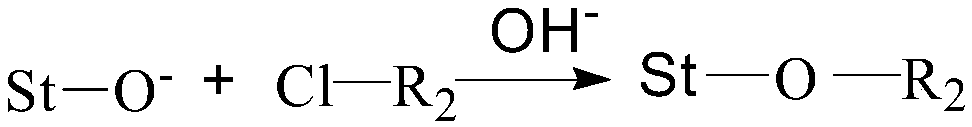

Method used

Image

Examples

preparation example Construction

[0057] The invention provides a preparation method of nano starch fluid loss reducer for drilling fluid, comprising the following steps:

[0058] S1, preparation of nano starch

[0059] Add 10-40 parts by mass of starch to 50-200 parts by mass of water, let stand at 5-10°C for 4-12 hours, and ultrasonically pulverize for 1-3 hours at <25°C, filter and take the filter cake to obtain the Need nano starch;

[0060] Standing for a period of time under a low temperature and constant temperature environment can make starch granules easier to be crushed by ultrasonic waves.

[0061] Place the static suspension in a 600-900W high-power ultrasonic pulverizer, and perform ultrasonic pulverization at <25°C to prevent starch granules from being unstable due to excessive temperature; the purpose of ultrasonic pulverization is to control starch granules Diameter, and then control the particle size of the final product fluid loss control agent, and the size of the particle size of the flui...

Embodiment 1

[0102] (1) Add 10 parts by mass of cornstarch to 50 parts by mass of water to prepare a suspension, and place it in a constant temperature environment at 5°C for 8 hours;

[0103] (2) Using a high-power ultrasonic pulverizer, the power is adjusted to 900W, and the suspension is ultrasonically pulverized for 1 hour in an environment < 25°C, and after filtration, the filter cake is taken to obtain the required nano starch;

[0104] (3) Add the nano starch into the stirrer, add 50 parts by mass of ethanol, heat to 40°C, feed nitrogen and stir;

[0105] (4) After stirring evenly, add 5 parts by mass of sodium hydroxide and 5 parts by mass of 3-chloro-2-hydroxypropanesulfonate sodium, react for 1 hour, and vacuum filter after the reaction is completed to obtain a filter cake;

[0106] (5) After washing the filter cake several times with ethanol, add it to 50 parts by mass of ethanol, heat to 60° C., feed nitrogen and stir at the same time, to obtain an etherification-modified nano-st...

Embodiment 2

[0119] (1) Add 30 parts by mass of tapioca starch to 180 parts by mass of water to prepare a suspension, and place it in a constant temperature environment at 8°C for 4 hours;

[0120] (2) Adopt a high-power ultrasonic pulverizer, adjust the power to 800W, and in the environment of <25°C, ultrasonically pulverize the suspension for 2.5 hours, and take the filter cake after filtration to obtain the required nano-starch;

[0121] (3) Add the nano starch into the stirrer, add 80 parts by mass of methanol, heat to 50° C., feed nitrogen and stir;

[0122] (4) After stirring evenly, add 10 parts by mass of sodium hydroxide and 20 parts by mass of sodium chloroacetate, react for 2 hours, and vacuum filter after completion of the reaction to obtain a filter cake;

[0123] (5) After washing the filter cake several times with ethanol, add it to 80 parts by mass of methanol, heat to 70° C., feed nitrogen and stir at the same time, to obtain an etherification-modified nano-starch suspensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com