Preparation method and application method of a lightweight water-retaining material

A water-retaining material and light-weight technology, applied in botany equipment and methods, soil preparation methods, planting substrates, etc., can solve the problems of unusable dwarf herbaceous plants, high cost and high cost of water-retaining layers, and achieve the promotion of above-ground biomass and underground Biomass, conservation of land resources, and improvement of physiological characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of lightweight porous water-retaining material: Weigh high-strength gypsum powder and soil at a mass ratio of 1:4, mix soil and water at a mass ratio of 25:9, stir to form a light material, and then Pile it into a hollow circular platform, mix high-strength gypsum powder and water according to the mass ratio of 5:3, and stir to form a slurry; finally, pour the slurry of high-strength gypsum powder and water into the hollow circular platform, and fully stir until it becomes yellowish brown Fluid, after the mixture is dried until the water content is less than or equal to 80%, an irregular lightweight porous water-retaining material is obtained; through actual tall fescue planting monitoring, the water retention rate of the lightweight porous water-retaining material prepared in this embodiment is increased by 60%.

Embodiment 2

[0024] (1) Preparation of lightweight porous water-retaining material: Weigh high-strength gypsum powder and soil at a mass ratio of 3:7, mix the soil with water at a mass ratio of 25:10, stir to form a lightweight material, and then Pile it into a hollow circular platform, mix high-strength gypsum powder and water according to the mass ratio of 5:4, and stir to form a slurry; finally, pour the slurry of high-strength gypsum powder and water into the hollow circular platform, and fully stir until it becomes yellowish-brown Fluid, after the mixture is dried until the water content is less than or equal to 80%, an irregular lightweight porous water-retaining material is obtained; through actual tall fescue planting monitoring, the water retention rate of the lightweight porous water-retaining material prepared in this embodiment is increased by 100%.

Embodiment 3

[0026] (1) Preparation of lightweight porous water-retaining material: Weigh high-strength gypsum powder and soil at a mass ratio of 2:3, mix soil with water at a mass ratio of 25:9, stir to form a lightweight material, and then Pile it into a hollow circular platform, mix the high-strength gypsum powder and water according to the mass ratio of 5:3, and stir it into a slurry; finally, pour the slurry of high-strength gypsum powder and water into the hollow circular platform, and fully stir it into yellowish brown Fluid, after the mixture is dried until the water content is less than or equal to 80%, an irregular lightweight porous water-retaining material is obtained; through actual tall fescue planting monitoring, the water retention rate of the lightweight porous water-retaining material prepared in this embodiment is increased by 100%.

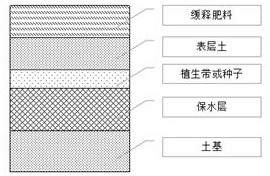

[0027] The use process of the irregular lightweight porous water-retaining material prepared in Examples 1 ~ 3 is (such as figure 1Shown):...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com