Microorganism producing poly-γ-glutamic acid and its construction method and application

A technology of glutamic acid, production method, applied in the field of genetic engineering and microbial fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

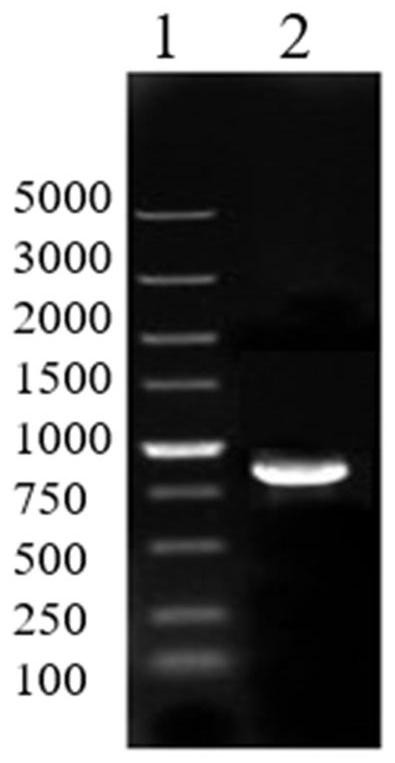

[0030] Example 1 Construction of pHY-plC expression plasmid

[0031] According to the gene sequence of the plC gene in the genome DNA sequence of Bacillus thuringiensis BM171, design the upstream primer (plC-F) and the downstream primer (plC-R) of plC gene; And take the genome DNA of Bacillus thuringiensis BM171 as template, respectively The upstream primer (plC-F) and downstream primer (plC-R) of the plC gene were used for PCR amplification to obtain a plC gene fragment with a length of 852bp (as shown in SEQ ID NO.2). The sequences of primers plC-F and plC-R are as follows.

[0032] SEQ ID NO.3:plC-F:TAAGAGAGGAATGTACACATGAAAAAGAAAGTACTTGCTT

[0033] SEQ ID NO.4:plC-R:TCCGTCCTCTCTGCTCTTTTAACGATTTCCGTACGTATCA

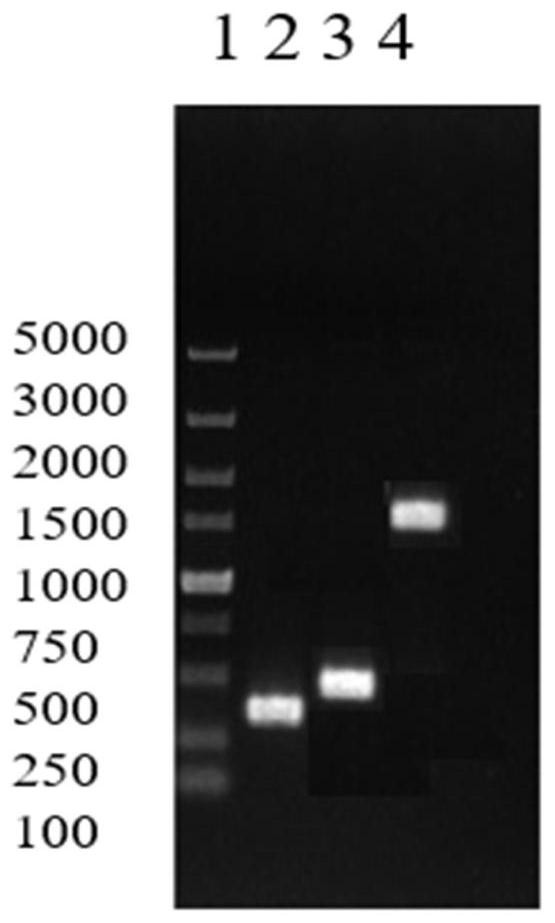

[0034] Using the genomic DNA of Bacillus subtilis 168 as a template and P43-F and P43-R as primers, the P43 promoter was amplified by PCR; using the genomic DNA of Bacillus licheniformis WX-02 as a template, TamyL-F and TamyL-R were Primers, amylase terminator TamyL ...

Embodiment 2

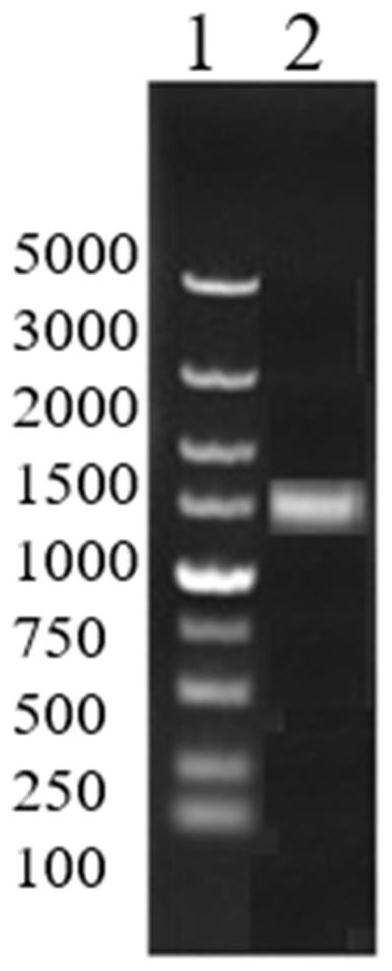

[0043] Example 2 Construction of Bacillus licheniformis WX-02 / pHY-plC

[0044] The free expression vector pHY-plC was transformed into Bacillus licheniformis WX-02 (this strain has been disclosed in Chinese patent CN106497857A), screened at 37°C on a medium containing tetracycline resistance, and obtained For the transformants, colony PCR verification was carried out on the extracted plasmids of the transformants (the primers used were: pHY-F and pHY-R). The PCR verification result of the positive transformant was an electrophoresis band at 1934bp, combined with the sequence determination results, it was proved that the free expression vector pHY-plC was successfully transferred into Bacillus licheniformis WX-02, and the Bacillus licheniformis engineering bacterium WX-02 / pHY- The construction of plC was successful, and the control strain WX-02 / pHY300 was to transform the plasmid pHY300 into WX-02, and the operation steps were the same as the construction of WX-02 / pHY-plC.

Embodiment 3

[0045] Example 3 Fermentation test of Bacillus licheniformis WX-02 / pHY-plC to produce γ-PGA

[0046] 1. Seed culture

[0047] Activate Bacillus licheniformis WX-02 / pHY-plC and WX-02 / pHY300, that is, inoculate 1% by volume from a glycerol tube into 5mL LB medium, culture at 180-300r / min at 37°C for 10 ~ 14 hours, and then inoculate the bacterium liquid after the activation of the strain in the LB medium with a volume percentage of 1% inoculum, and then cultivate it at 180 ~ 300 r / min and 37 ° C for 10 ~ 12 hours to obtain the seed culture bacterium liquid.

[0048] 2. Production of γ-PGA by fermentation

[0049] In order to better analyze the effect of the expression of plC on the fermentative production of γ-PGA by Bacillus licheniformis, fermentation experiments were carried out using the media shown in Table 1, respectively.

[0050] Table 1 Fermentation medium formula

[0051]

[0052]

[0053] The units of the above medium components are g / L.

[0054] 25-150 mL o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com