A device for obtaining a nanocrystalline-amorphous composite layer on the surface of pure titanium and its preparation method

A nanocrystalline and composite layer technology, which is applied in the field of devices and preparations for obtaining nanocrystalline-amorphous composite layers on the surface of pure titanium, can solve the problems of high experimental conditions and high energy consumption, and achieve controllable process parameters Strong performance, low energy consumption and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

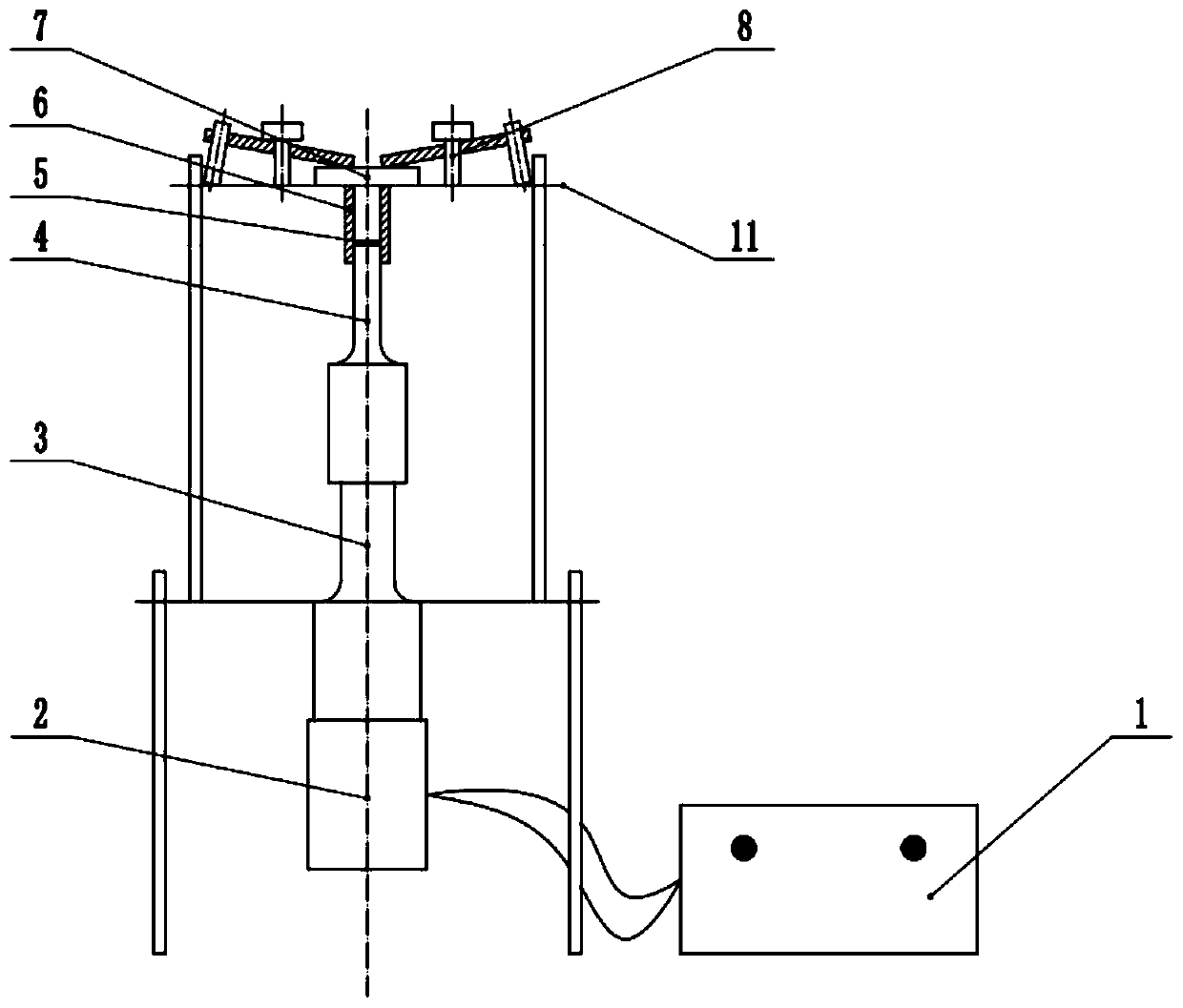

[0055] 1. A device for obtaining a nanocrystalline-amorphous composite layer on the surface of pure titanium, such as figure 1 As shown, the device includes: an ultrasonic vibration application module and a shot peening working module.

[0056] The ultrasonic vibration application module mainly includes: an ultrasonic generator 1 , an ultrasonic transducer 2 , and an ultrasonic horn 3 .

[0057] The shot peening working module mainly includes: an ultrasonic tool head 4 , a shot peening 5 , a shot peening chamber 6 , a workpiece table 11 , and a workpiece fixing device (a) 8 .

[0058] The ultrasonic generator 1, the ultrasonic transducer 2, and the ultrasonic horn 3 are connected in sequence. The ultrasonic generator 1 transmits the current signal and transmits the signal to the ultrasonic transducer 2. The ultrasonic transducer 2 converts this signal into mechanical vibration with the same frequency. The ultrasonic horn 3 converts the mechanical vibration generated by the ul...

Embodiment 2

[0069] 1. A device for obtaining a nanocrystalline-amorphous composite layer on the surface of pure titanium, the same as in Embodiment 1.

[0070] 2. A method for obtaining a nanocrystalline-amorphous composite layer on the surface of pure titanium using the above-mentioned device of this embodiment; the method includes the following steps:

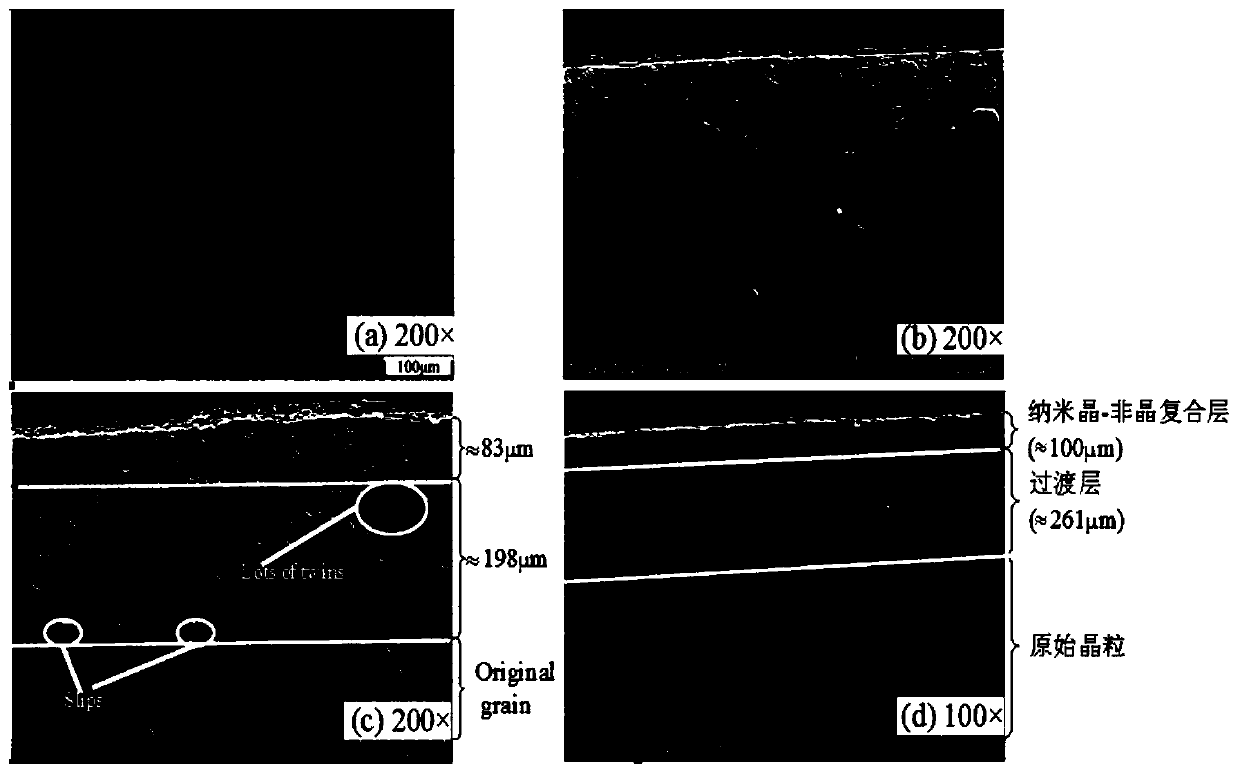

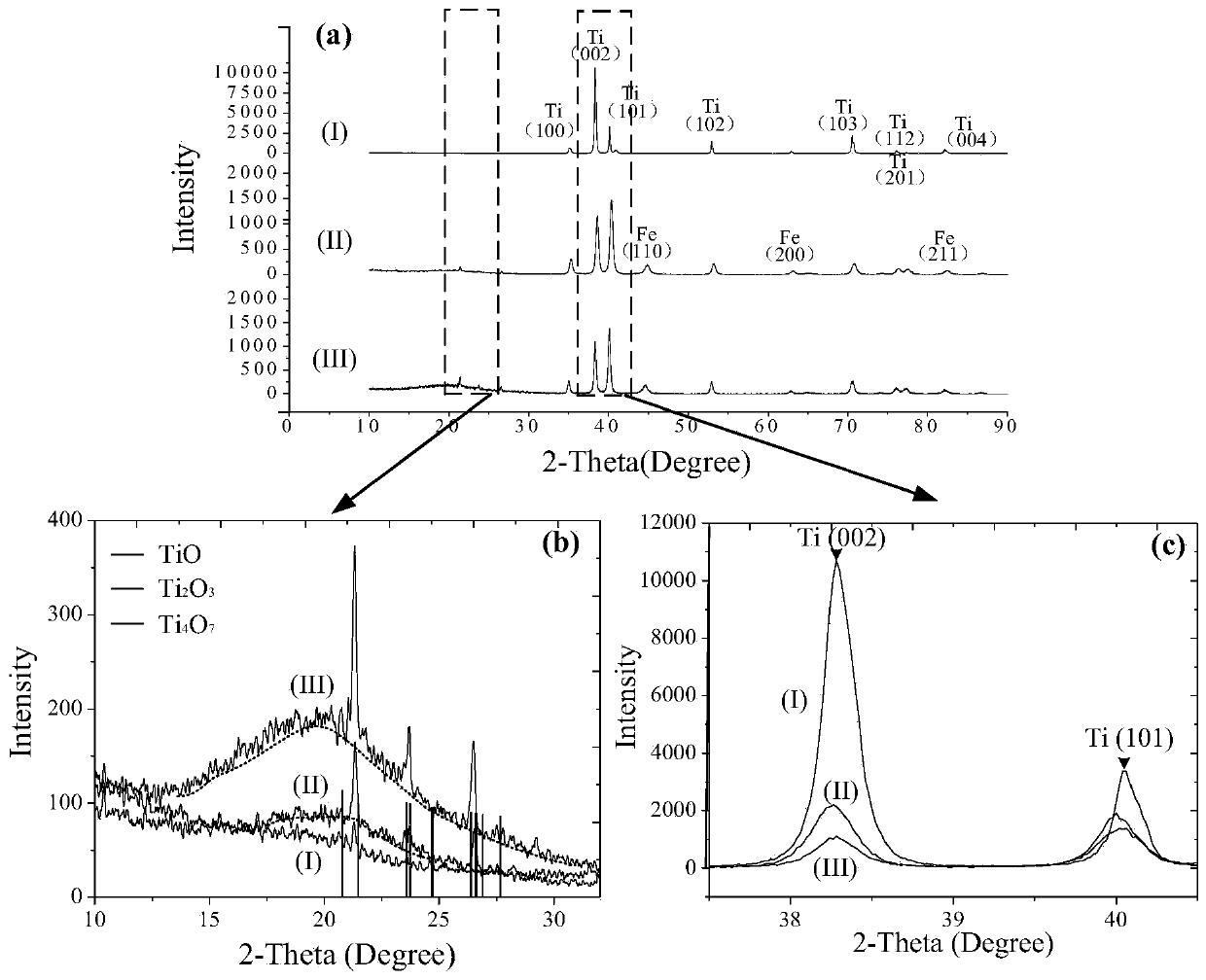

[0071] 1) Preparation: Put the ceramic pellets with a diameter of 2mm and a hardness of about 120-135HRC into the shot peening chamber. The number of ceramic pellets just covers the bottom of the shot peening chamber. The annealed cold-rolled pure titanium (TA2, Fe 0.03 C 0.08 N 0.03 H 0.014 O 0.015 Ti bal )) is fixed on the upper surface of the workpiece fixing device (a) 8, and the distance between the ultrasonic tool head 4 and the sample is adjusted to 7.5 mm; finally, the working frequency and power of the ultrasonic generator 1 are adjusted to make the amplitude of the ultrasonic tool head 4 The adjustment is 32um, and the wo...

Embodiment 3

[0076] 1. A device for obtaining a nanocrystalline-amorphous composite layer on the surface of pure titanium, the same as in Embodiment 1.

[0077] 2. A method for obtaining a nanocrystalline-amorphous composite layer on the surface of pure titanium using the above-mentioned device of this embodiment; the method includes the following steps:

[0078] 1) Preparation work: Put stainless steel shot with a diameter of 3mm and a hardness of about 45-55HRC into the shot peening chamber. The number of stainless steel shot just covers the bottom of the shot peening chamber. The annealed cold-rolled pure titanium (TA2, Fe 0.03 C 0.08 N 0.03 H 0.014 O 0.015 Ti bal )) is fixed on the upper surface of the workpiece fixing device (a) 8, and the distance between the ultrasonic tool head 4 and the sample is adjusted to 7.5 mm; finally, the working frequency and power of the ultrasonic generator 1 are adjusted to make the amplitude of the ultrasonic tool head 4 The adjustment is 40um, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com