Abrasion-resistant gear with self-adaptive function and manufacturing method thereof

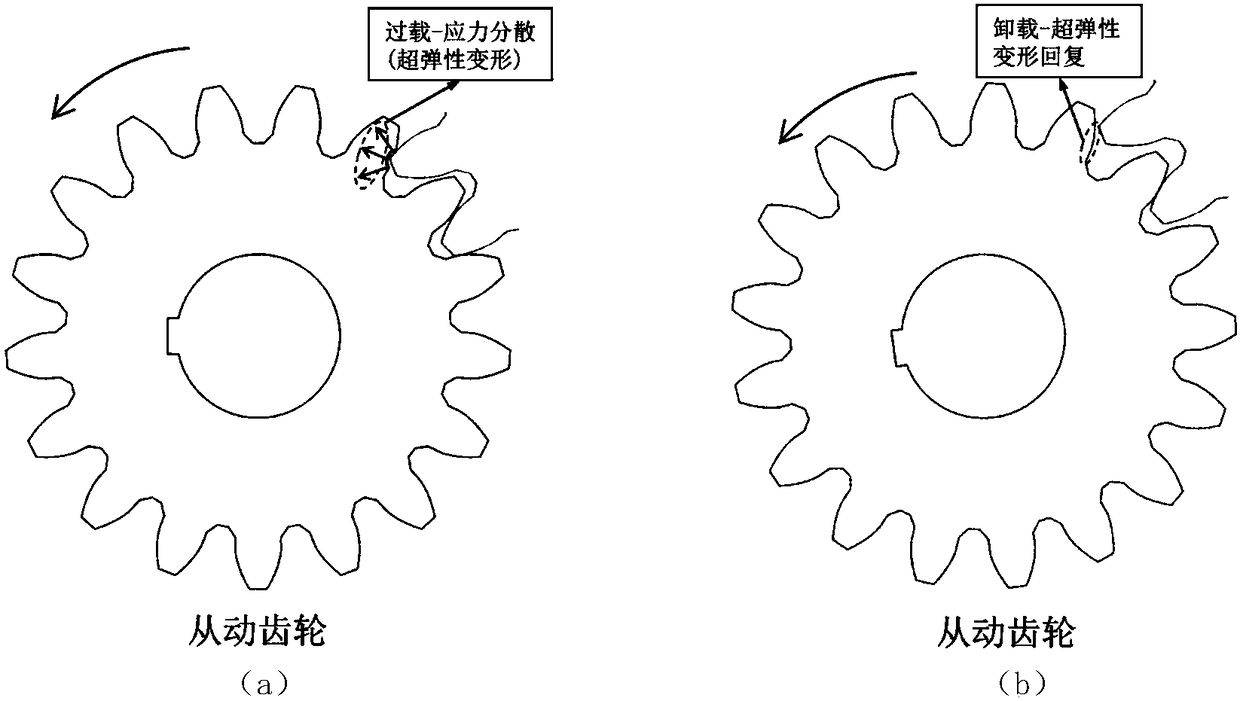

A manufacturing method and self-adaptive technology, applied in the field of mechanical parts manufacturing, can solve the problems of increased tooth surface wear, plastic deformation of the tooth surface, gear failure, etc., and achieve the effects of reducing the gear wear rate, increasing the contact area, and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Ti, Ni, and Si elemental powders are selected according to a molar ratio of 52.5:39.5:8. The particle size of the powder is about 30 μm, the purity is 99.7%, and the spheroidization rate is 99%. Mix the elemental powders of the three elements evenly, and the bulk density of the mixed powder is 3.3g / cm 3 .

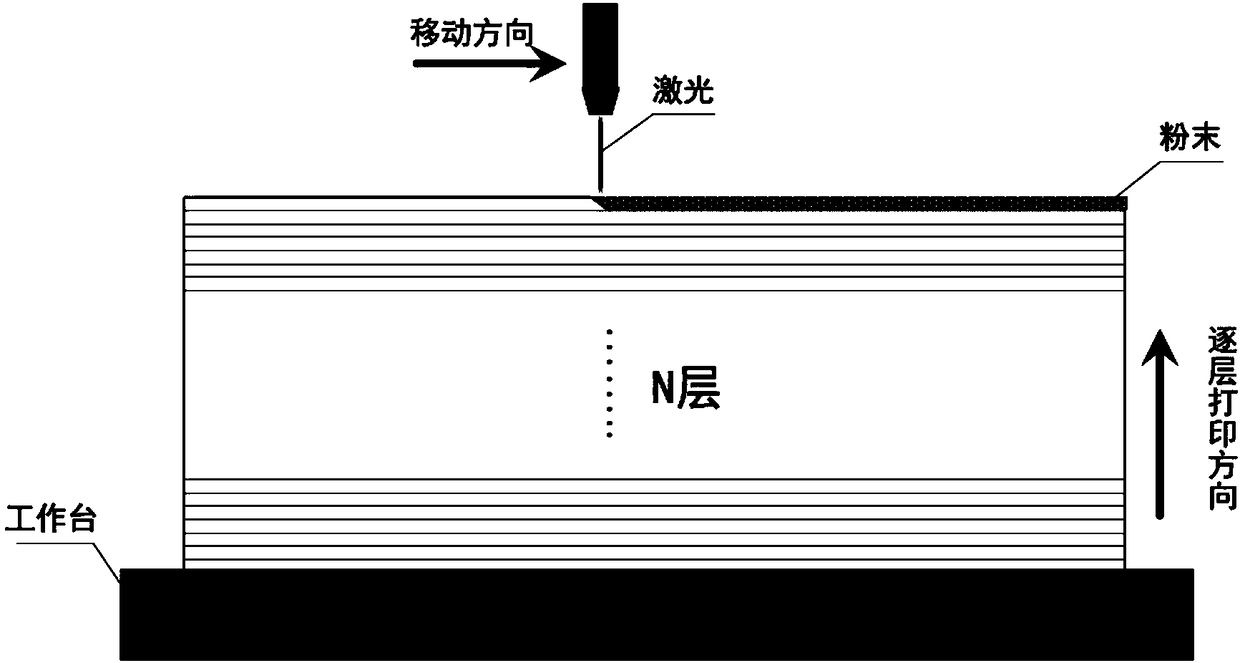

[0039] (2) Use the 3D CAD modeling software Solidworks to establish a 3D model of the gear, and then slice the model to generate a 2D sliced model, which is imported into the computer control system of the 3D printing molding device.

[0040] (3) Set the 3D printing process parameters based on the selected laser melting (SLM) technology: the thickness of the powder layer is 30 μm, the laser power is 300 W, the spot diameter is 80 μm, the scanning speed is 1600 mm / s, and the scanning distance is 60 μm.

[0041] (4) Introduce argon gas protection into the molding cavity, and control the automatic powder spreading device to evenly spread powder on the substrate i...

Embodiment 2

[0045] (1) Ti, Ni, and B elemental powders are selected according to a molar ratio of 46:38:16. The particle size of the powder is about 60 μm, the purity is 99.8%, and the spheroidization rate is 99%. Mix the elemental powders of the three elements evenly, and the bulk density of the mixed powder is 2.4g / cm 3 .

[0046] (2) Use the 3D CAD modeling software Solidworks to establish a 3D model of the gear, and then slice the model to generate a 2D sliced model, which is imported into the computer control system of the 3D printing molding device.

[0047] (3) Set the 3D printing process parameters based on the selected laser melting (SLM) technology: the thickness of the powder layer is 40 μm, the laser power is 150 W, the spot diameter is 80 μm, the scanning speed is 700 mm / s, and the scanning distance is 50 μm.

[0048] (4) Introduce argon gas protection into the molding cavity, and control the automatic powder spreading device to evenly spread powder on the substrate in the...

Embodiment 3

[0052] (1) Select TiNi / TiC composite material powder with a ratio of Ti, Ni, and C of 50:30:20. The particle size of the powder is about 50 μm, the purity is 99.8%, and the spheroidization rate is 99%. Mix the elemental powders of the three elements evenly, and the bulk density of the mixed powder is 2.6g / cm 3 .

[0053] (2) Use the 3D CAD modeling software Solidworks to establish a 3D model of the gear, and then slice the model to generate a 2D sliced model, which is imported into the computer control system of the 3D printing molding device.

[0054] (3) Set the 3D printing process parameters based on the selected laser melting (SLM) technology: the thickness of the powder layer is 60 μm, the laser power is 100 W, the spot diameter is 80 μm, the scanning speed is 200 mm / s, and the scanning distance is 80 μm.

[0055] (4) Introduce argon gas protection into the molding cavity, and control the automatic powder spreading device to evenly spread powder on the substrate in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com