A method for improving the uniformity of doping concentration of silicon epitaxial layer for photoelectric sensors

A photoelectric sensor and doping concentration technology, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of poor consistency and achieve the effect of improving the consistency of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

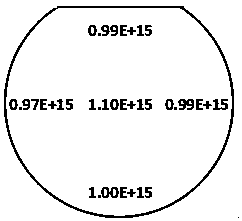

Embodiment 1

[0028] The first step is to pass hydrogen into the reaction chamber. The hydrogen flow rate is set to 20L / min, and then the hydrogen chloride gas is passed into it. The hydrogen chloride gas flow rate is set to 30L / min, and the residual deposits on the epitaxial reaction base are engraved at high temperature. For corrosion, the reaction temperature is set to 1080 ℃, the reaction time is set to 5 min; the second step, the hydrogen flow is set to 150L / min, the gaseous trichlorosilane is introduced, the flow is set to 6 L / min, and the deposition The time is set to 2 min, and the surface of the epitaxial reaction base is covered with a layer of undoped polysilicon.

[0029] In the third step, the silicon substrate is loaded on the polysilicon layer on the epitaxial reaction base, and the epitaxial reaction chamber is purged with nitrogen and hydrogen in sequence. The flow of nitrogen is set to 100 L / min, and the flow of hydrogen is set to 150 L / min, the cavity purge time is set to 10...

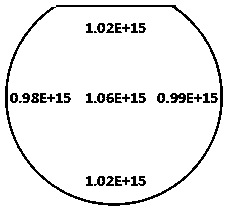

Embodiment 2

[0037] The first step is to pass hydrogen into the reaction chamber. The hydrogen flow rate is set to 20L / min, and then the hydrogen chloride gas is passed into it. The hydrogen chloride gas flow rate is set to 30L / min, and the residual deposits on the epitaxial reaction base are engraved at high temperature. For corrosion, the reaction temperature is set to 1080℃, and the reaction time is set to 5 min;

[0038] The second step is to set the hydrogen flow rate to 150L / min, pass in the gaseous trichlorosilane, set the flow rate to 6 L / min, set the deposition time to 2 min, and cover the surface of the base with a layer of undoped Polysilicon

[0039] The third step is to load the silicon substrate on the polysilicon on the epitaxial reaction pedestal, and purge the epitaxial reaction chamber with nitrogen and hydrogen in sequence. The flow of nitrogen is set to 100 L / min, and the flow of hydrogen is set to 150 L / min, the cavity purge time is set to 10 min.

[0040] The fourth step ...

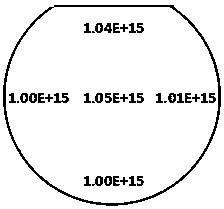

Embodiment 3

[0048] The first step is to pass hydrogen into the reaction chamber. The hydrogen flow rate is set to 20L / min, and then the hydrogen chloride gas is passed into it. The hydrogen chloride gas flow rate is set to 30L / min, and the residual deposits on the epitaxial reaction base are engraved at high temperature. For corrosion, the reaction temperature is set to 1080 ℃, and the reaction time is set to 5 min.

[0049] The second step is to set the hydrogen flow rate to 150L / min, pass in the gaseous trichlorosilane, set the flow rate to 6 L / min, set the deposition time to 2 min, and cover the surface of the epitaxial reaction base with no doped Miscellaneous polysilicon.

[0050] The third step is to load the silicon substrate on the polysilicon on the epitaxial reaction pedestal, and purge the epitaxial reaction chamber with nitrogen and hydrogen in sequence. The flow of nitrogen is set to 100 L / min, and the flow of hydrogen is set to 150 L / min, the cavity purge time is set to 10 min....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com