Preparation method of flawless photonic crystal

A photonic crystal, crack-free technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., to achieve the effect of increasing peak intensity, improving optical performance, and good regulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

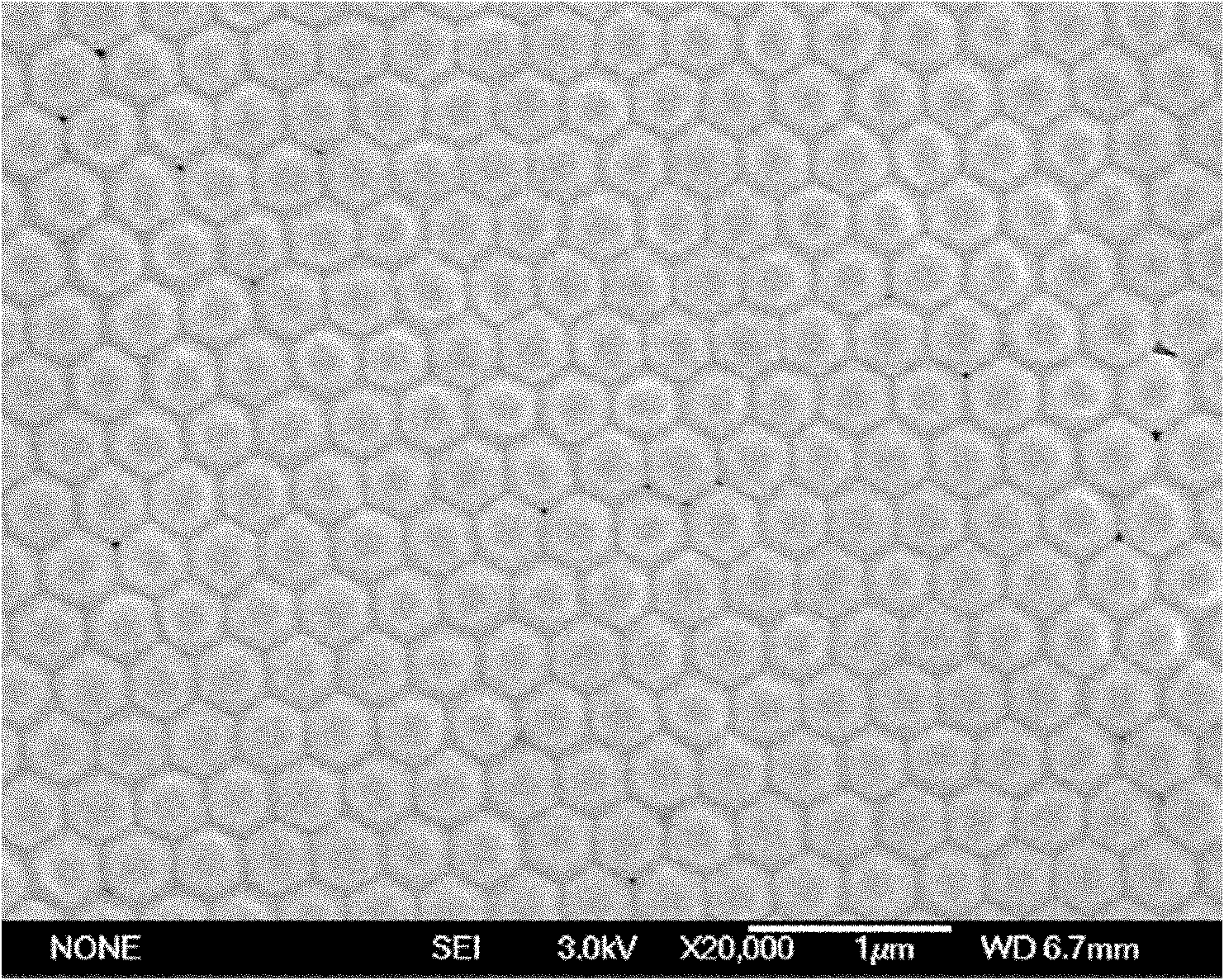

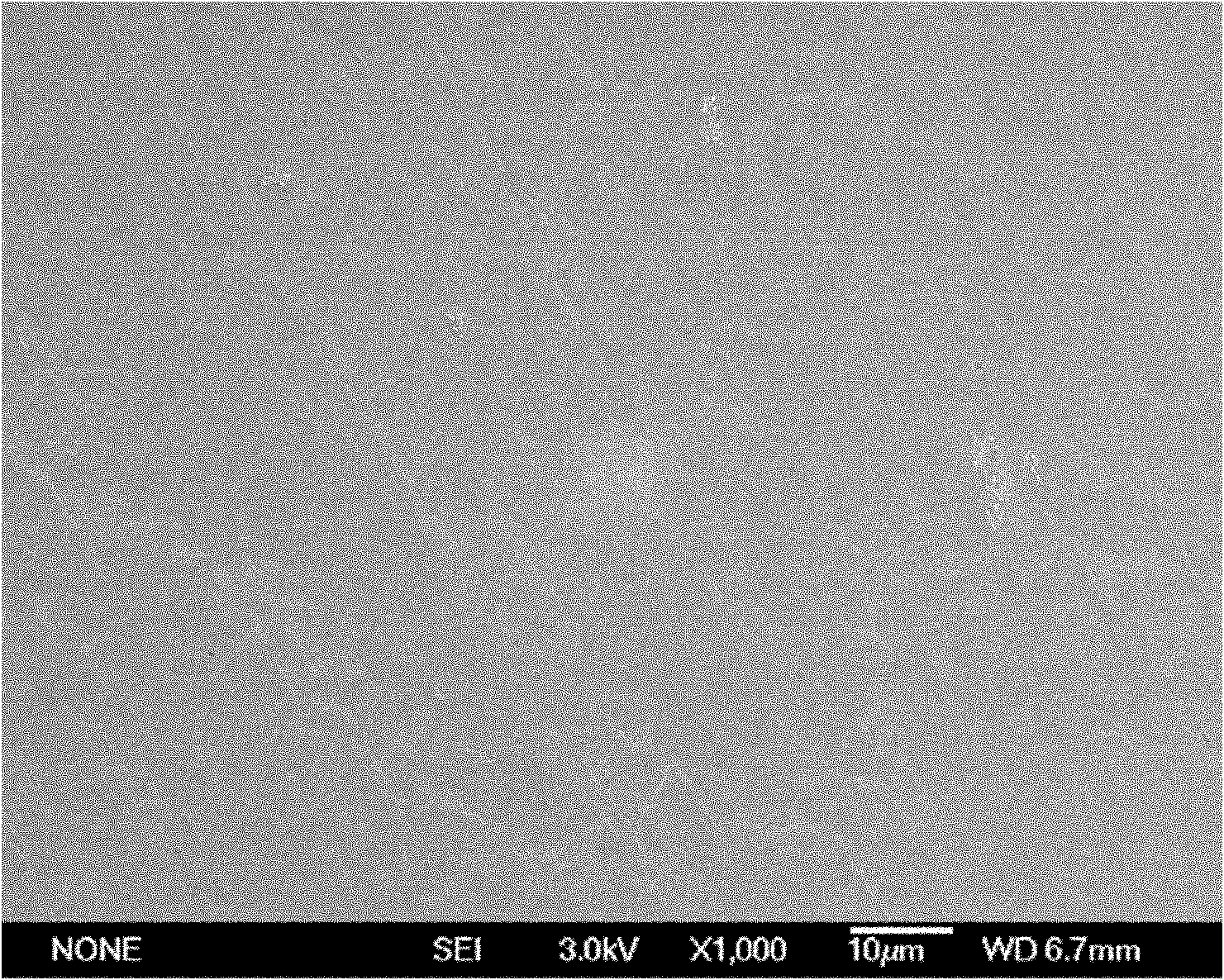

[0030] Ultrasonic dispersion of monodisperse poly(styrene-methyl methacrylate-acrylic acid) latex particles with a particle size of 80 nm, acrylic acid, N-N'-methylenebisacrylamide crosslinking agent and potassium persulfate initiator in water , forming a mixture emulsion (the concentration of the mixture emulsion is 0.1102wt%), wherein, the concentration of the monodisperse poly(styrene-methyl methacrylate-acrylic acid) latex particle in the mixture emulsion is 0.1wt%, acrylic acid and monodisperse poly The mass ratio of (styrene-methyl methacrylate-acrylic acid) latex particles is 0.1: 1, and the mass ratio of acrylic acid: N-N'-methylenebisacrylamide: potassium persulfate is 1: 0.01: 0.01; The mixture emulsion obtained above was spin-coated onto the surface of an aluminum foil with a thickness of 0.02 mm, and then the monodisperse poly(styrene-methyl methacrylate-acrylic acid) The latex particles self-assembled on the surface of the aluminum foil, and at the same time therm...

Embodiment 2

[0032] Monodisperse poly(styrene-methyl methacrylate-acrylic acid) latex particles with a particle size of 1100nm, acrylamide, N-N'-methylenebisacrylamide crosslinking agent, ammonium persulfate and potassium persulfate The mixture (the mass ratio of ammonium persulfate and potassium persulfate is 1:1) is ultrasonically dispersed in water to form a mixture emulsion (the concentration of the mixture emulsion is 33.36wt%), wherein the monodisperse poly(styrene-formaldehyde) in the mixture emulsion The concentration of poly(styrene-methyl methacrylate-acrylic acid) latex particles is 30wt%, the mass ratio of acrylamide and monodisperse poly(styrene-methyl methacrylate-acrylic acid) latex particles is 0.1:1, acrylamide: N-N' - methylenebisacrylamide: the mass ratio of the mixture of ammonium persulfate and potassium persulfate is 1: 0.06: 0.06; the mixture emulsion obtained above is sprayed onto the surface of titanium foil with a thickness of 0.7mm, and then heated at a temperatur...

Embodiment 3

[0034] Monodisperse poly(styrene-methyl methacrylate-acrylic acid) latex particles with a particle size of 80nm and a particle size of 250nm were mixed with crotonic acid, N-N'-methylenebisacrylamide crosslinking agent and The mixture of ammonium persulfate, potassium persulfate and azobisisobutyronitrile (the mass ratio of the three is 1:1:1) is ultrasonically dispersed in water to form a mixture emulsion (the concentration of the two mixture emulsions is 7.04wt%), Wherein, in 2 kinds of mixture emulsions, the concentration of two kinds of monodisperse poly(styrene-methyl methacrylate-acrylic acid) latex particles is 5wt% respectively, crotonic acid and monodisperse poly(styrene-methyl methacrylate) The mass ratio of -acrylic acid) latex particles is 0.4: 1, and the mass ratio of crotonic acid: N-N'-methylenebisacrylamide: the mixture of ammonium persulfate, potassium persulfate and azobisisobutyronitrile is all 1: 0.01: 0.01; the two mixture emulsions obtained above were res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com