Polymer solid electrolyte material, solid electrolyte membrane and method for preparing same

A technology of solid electrolyte membrane and solid electrolyte, applied in circuits, electrical components, secondary batteries, etc., can solve the problem of low room temperature ionic conductivity, achieve high room temperature ionic conductivity, enhance high temperature resistance and mechanical strength, and improve The effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

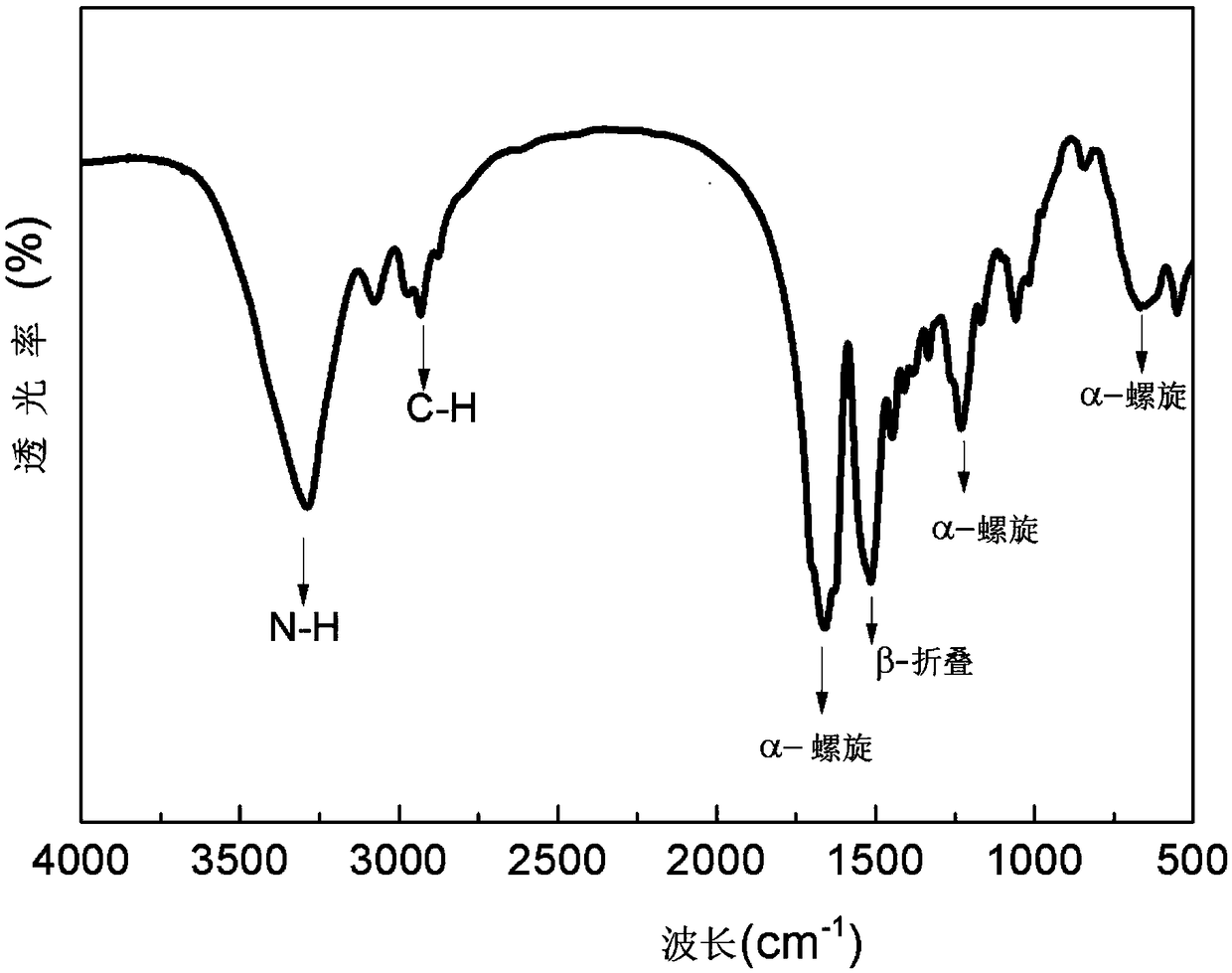

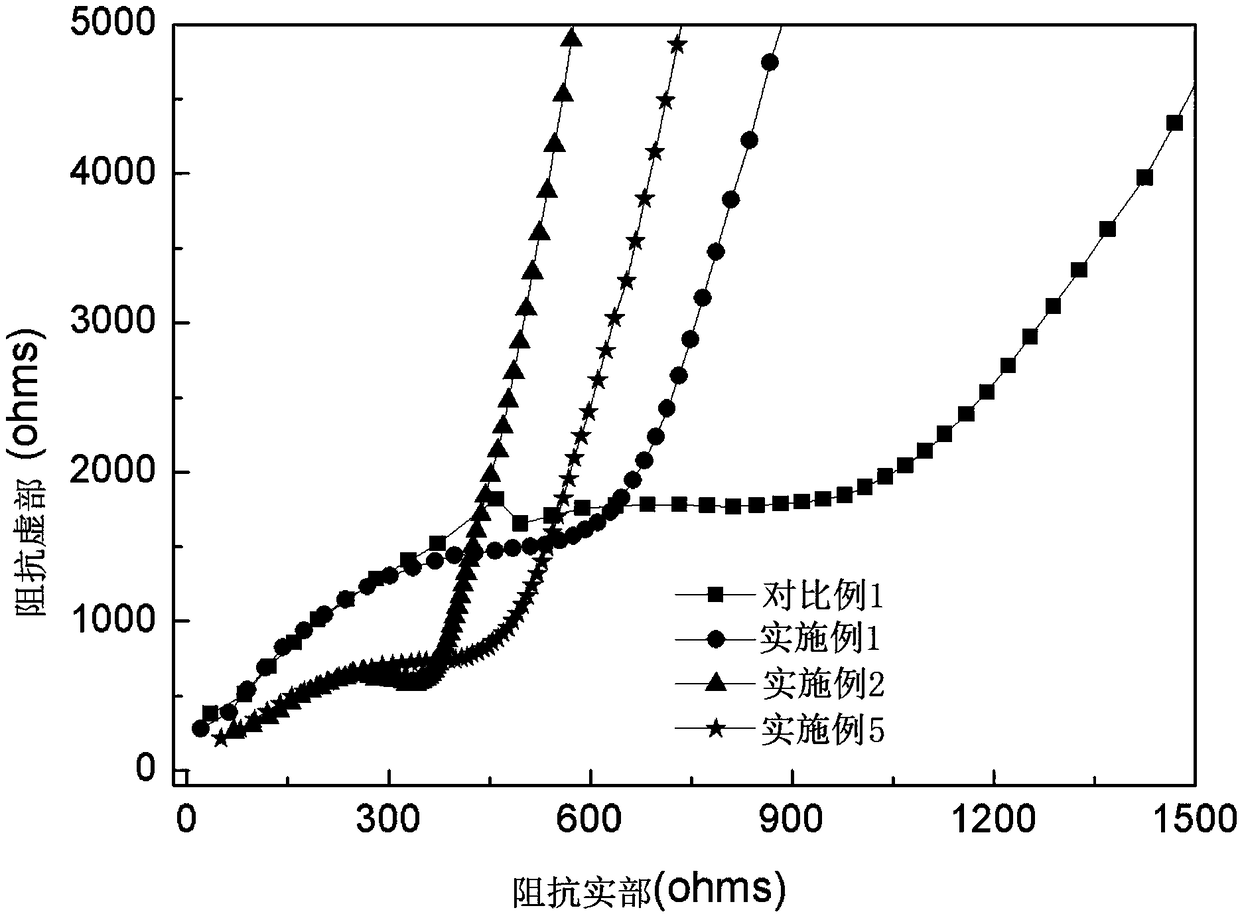

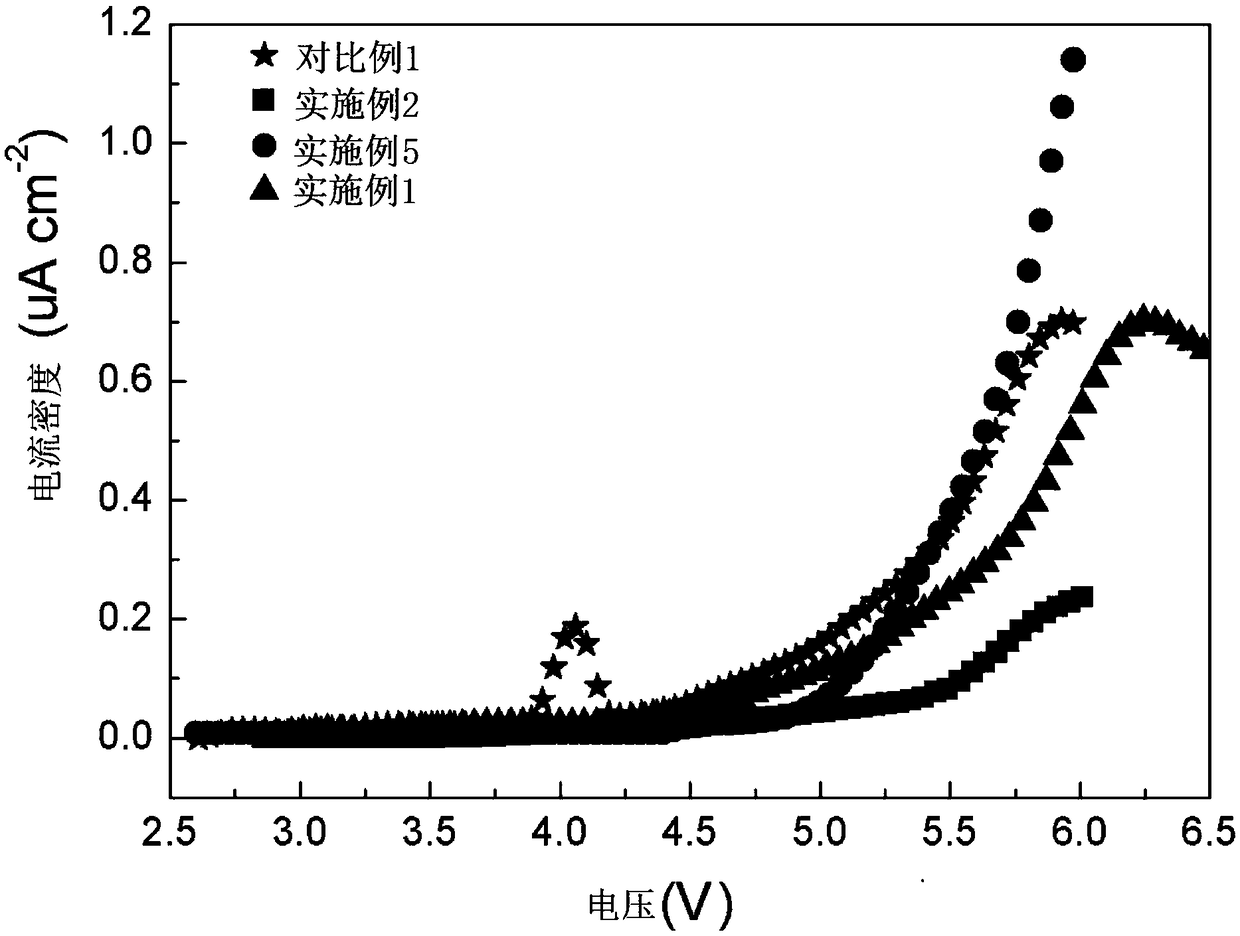

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing a polymer solid electrolyte membrane, comprising the following steps:

[0030] 1) Dissolving silk fibroin in water to form an aqueous solution of silk fibroin with a concentration of 4-9% (w / v), and putting it in a refrigerator at -20-4°C to refrigerate for later use. Since silk fibroin is easy to expire and deteriorate, it needs to be stored under low temperature conditions.

[0031] 2) In a stirring state, add the polymer matrix material into the silk fibroin aqueous solution, and stir for 12-48 hours to obtain a mixed solution.

[0032] Wherein, the stirring rate is 30-500 rpm / min.

[0033] 3) adding the lithium salt into the mixed solution and stirring for 12-48 hours to obtain a solid electrolyte solution.

[0034] Wherein, the stirring rate is 30-500 rpm / min.

[0035] 4) Coating the solid electrolyte solution on the mold and drying it to obtain the polymer solid electrolyte membrane.

Embodiment 1

[0038] A polymer solid state electrolyte material comprises lithium salt, polymer matrix material and silk fibroin, the content of lithium salt is 5wt%, the content of polymer matrix material is 30wt%, and the content of silk fibroin is 65wt%.

[0039] Wherein, silk fibroin is mulberry silk fibroin. The lithium salt is lithium bistrifluoromethylsulfonyl imide. The polymer matrix material is a mixture of polyvinyl alcohol and polyoxyethylene, wherein the mass ratio of polyvinyl alcohol to polyoxyethylene is 1.5:1.

[0040] A polymer solid-state electrolyte membrane, comprising the above-mentioned polymer solid-state electrolyte material.

[0041] A method for preparing a polymer solid electrolyte membrane, comprising the following steps:

[0042] 1) Dissolving silk fibroin in water to form a silk fibroin aqueous solution with a concentration of 6% (w / v), and putting it in a refrigerator at 4°C for later use;

[0043] 2) In a stirring state, add the polymer matrix material in...

Embodiment 2

[0047] A polymer solid electrolyte material comprises lithium salt, polymer matrix material and silk fibroin, the content of lithium salt is 10wt%, the content of polymer matrix material is 40wt%, and the content of silk fibroin is 50wt%.

[0048] Wherein, silk fibroin is spider silk fibroin. The lithium salt is a mixture of lithium bistrifluoromethanesulfonyl imide and lithium perchlorate trihydrate. The polymer matrix material is a one-component water-based polyurethane emulsion, specifically: 2-heptyl-3,4-bis(9-isocyanatononyl) 1-pentylcyclohexylamine, wherein bistrifluoromethyl The mass ratio of lithium sulfonylimide to lithium perchlorate trihydrate is 1:1.

[0049] A polymer solid-state electrolyte membrane, comprising the above-mentioned polymer solid-state electrolyte material.

[0050] A method for preparing a polymer solid electrolyte membrane, comprising the following steps:

[0051] 1) Dissolving silk fibroin in water to form an aqueous silk fibroin solution wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com