Polyether-ether-ketone (PEEK) 3D printing material and 3D printing forming method thereof

A 3D printing, polyetheretherketone technology, applied in the field of 3D printing, can solve the problems of difficulty in enhancing the effect, poor uniformity of 3D printing materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

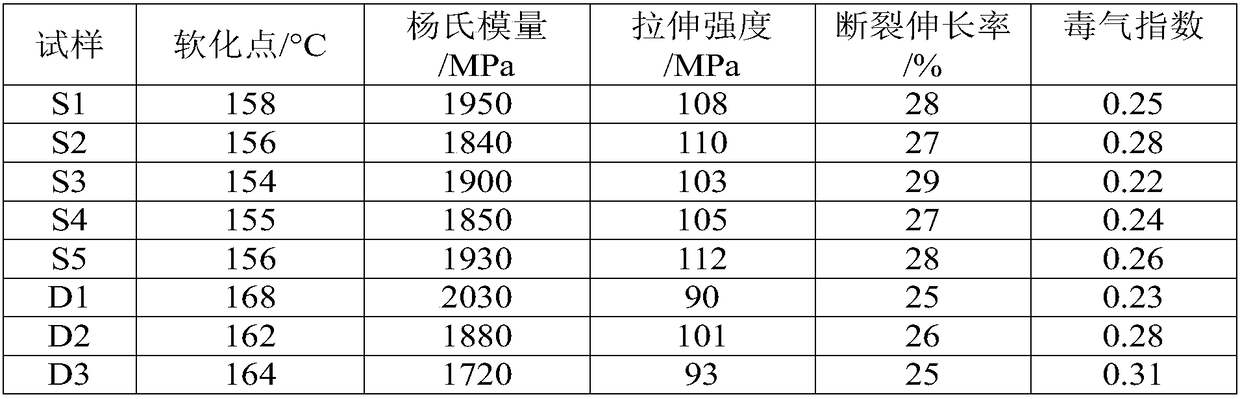

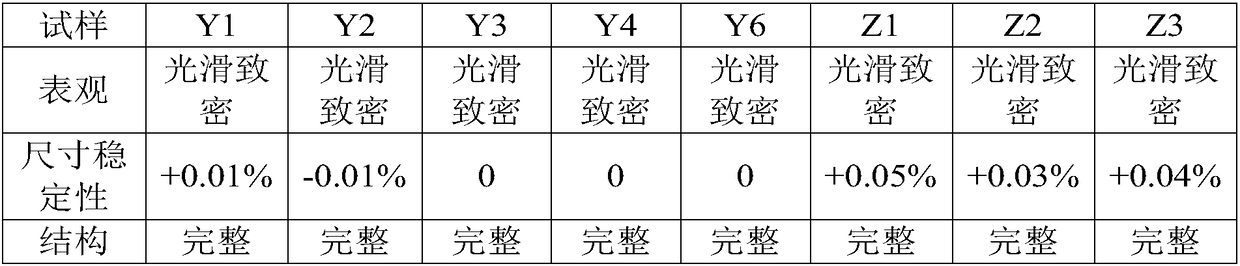

Examples

Embodiment 1

[0032] A polyetheretherketone 3D printing material

[0033] Recipe: polyetheretherketone 1000g, methylenebisacrylamide 100g, polyetherimide 20g

[0034] The preparation method comprises the following steps:

[0035] Step 1, dissolving 1000g of polyetheretherketone in 1000mL of concentrated sulfuric acid to obtain sulfonated polyetheretherketone;

[0036] Step II, dissolving 100 g of methylenebisacrylamide in water to obtain a methylenebisacrylamide solution with a concentration of 0.1 mol / L;

[0037] Step III, mixing the sulfonated polyether ether ketone obtained in step I with the methylenebisacrylamide solution obtained in step II to obtain PEEK-MBA;

[0038] Step IV: Dry the PEEK-MBA obtained in Step III at a temperature of 120°C for 30 minutes, then mix it with 20g of polyetherimide, and extrude it with a twin-screw extruder at a temperature of 380°C. Screw speed is 300rpm, obtains PEEK-MBA-PEI blend;

[0039] Step V, adding the PEEK-MBA-PEI blend obtained in Step IV i...

Embodiment 2

[0043] A polyetheretherketone 3D printing material

[0044] Recipe: 1000g polyetheretherketone, 1000g methylenebisacrylamide, 100g polyetherimide

[0045] The preparation method comprises the following steps:

[0046] Step 1, dissolving 1000g of polyetheretherketone in 3000mL of concentrated sulfuric acid to obtain sulfonated polyetheretherketone;

[0047] Step II, dissolving 1000g methylenebisacrylamide in water to obtain a methylenebisacrylamide solution with a concentration of 2.0mol / L;

[0048] Step III, mixing the sulfonated polyether ether ketone obtained in step I with the methylenebisacrylamide solution obtained in step II to obtain PEEK-MBA;

[0049] Step IV: Dry the PEEK-MBA obtained in Step III at a temperature of 130°C for 90 minutes, then mix it with 100g of polyetherimide, and extrude it with a twin-screw extruder at a temperature of 390°C. Screw speed is 300rpm, obtains PEEK-MBA-PEI blend;

[0050] Step V, adding the PEEK-MBA-PEI blend obtained in Step IV in...

Embodiment 3

[0054] A polyetheretherketone 3D printing material

[0055] Recipe: 1000g polyetheretherketone, 550g methylenebisacrylamide, 60g polyetherimide

[0056] The preparation method comprises the following steps:

[0057] Step 1, dissolving 1000g of polyetheretherketone in 2000mL of concentrated sulfuric acid to obtain sulfonated polyetheretherketone;

[0058] Step II, dissolving 550g methylenebisacrylamide in water to obtain a methylenebisacrylamide solution with a concentration of 1.1mol / L;

[0059] Step III, mixing the sulfonated polyether ether ketone obtained in step I with the methylenebisacrylamide solution obtained in step II to obtain PEEK-MBA;

[0060] Step IV: Dry the PEEK-MBA obtained in Step III at a temperature of 125°C for 60 minutes, then mix it with 60g of polyetherimide, and extrude it with a twin-screw extruder at a temperature of 385°C. Screw speed is 300rpm, obtains PEEK-MBA-PEI blend;

[0061] Step V, adding the PEEK-MBA-PEI blend obtained in Step IV into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com