Method for recovery of valuable metals from cigs solar thin film cell chamber waste

A solar thin film, valuable metal technology, applied in the improvement of process efficiency, instruments, optics, etc., can solve the problems of high production cost, complicated and dangerous operation, incomplete separation, etc., and achieve high-efficiency selective leaching, simple process flow, The effect of meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

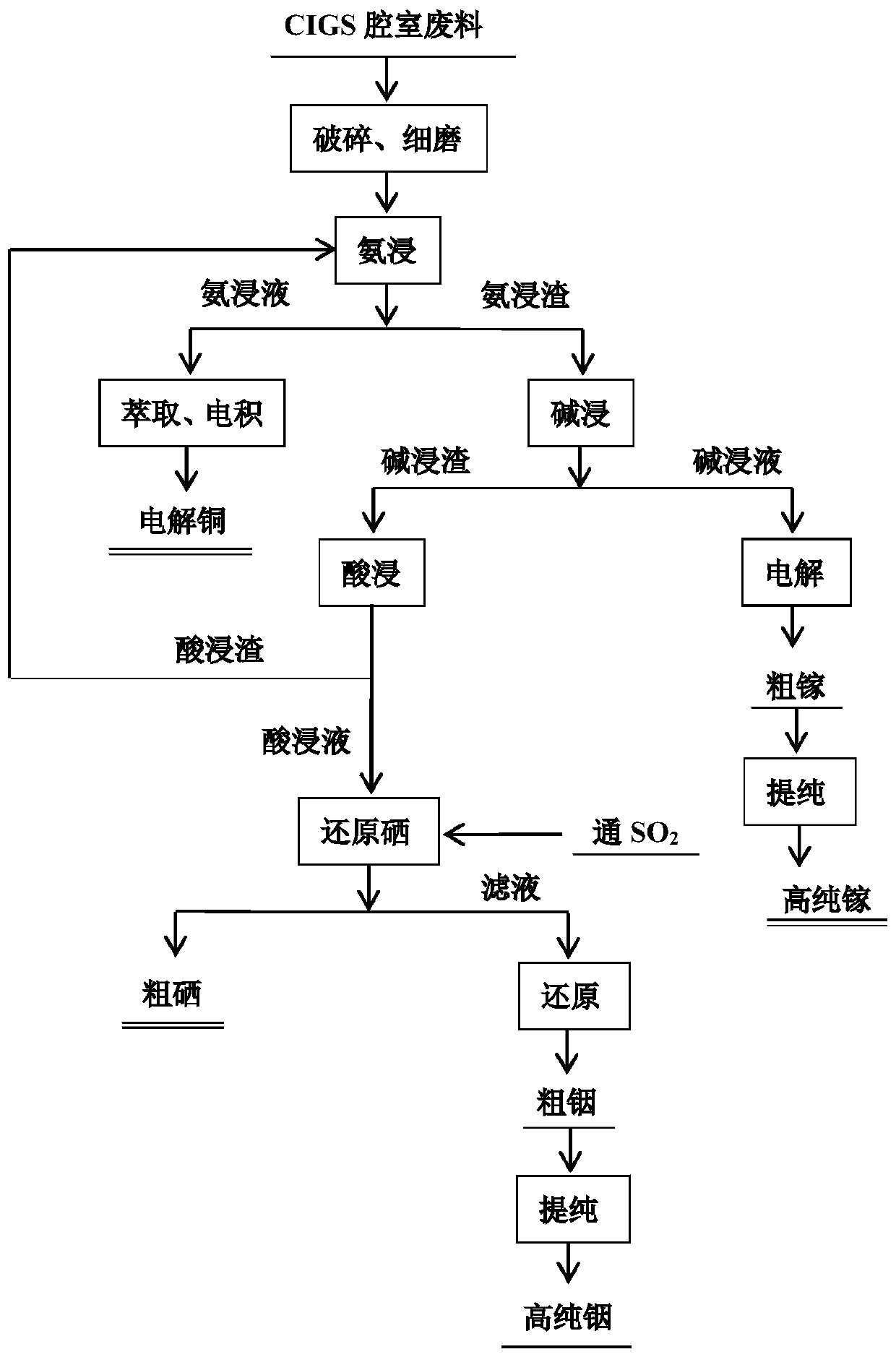

[0043] like figure 1 As shown, the implementation steps of this embodiment include: taking 50g of CIGS solar thin film battery chamber waste for crushing and fine grinding, using ammonia and ammonium salt mixture solution of a certain mass concentration as a leaching agent to carry out ammonia leaching, and the ammonia concentration is 350g / L ( with NH 3The solid-liquid ratio before leaching is 5:1g / mL, the leaching temperature is 30°C, and the leaching time is 5h. After the leaching is completed, the ammonia leaching solution and ammonia leaching residue are obtained through liquid-solid separation; Electrolytic copper can be obtained; the ammonia leaching slag uses 80% NaOH solution as the leaching agent for alkaline leaching under normal pressure conditions. The leaching temperature of the alkaline leaching process is 40°C, the leaching time is 4.5h, and the solid-liquid ratio before leaching is 10:1g / mL, after leaching, the alkali leaching solution and alkali leaching res...

Embodiment 2

[0045] The implementation steps of this embodiment include: taking 100g CIGS solar thin film cell chamber waste material and crushing, finely grinding, carrying out ammonia leaching with a certain concentration of ammonia-containing solution as the leaching agent, ammonia concentration 250g / L (in the form of NH 3 The solid-liquid ratio before leaching is 1:10g / mL, the leaching temperature is 60°C, and the leaching time is 3h. After the leaching is completed, ammonia leaching solution and ammonia leaching residue are obtained through liquid-solid separation; after ammonia leaching solution extraction and electrowinning Electrolytic copper can be obtained; the ammonia leaching slag uses KOH solution with a mass concentration of 60% as the leaching agent for alkaline leaching under pressure. The leaching temperature of the alkaline leaching process is 30°C, the leaching time is 4.5h, and the solid-liquid ratio before leaching is 1:5g / mL, after leaching, the alkali leaching solutio...

Embodiment 3

[0047] The implementation steps of this embodiment include: taking 50g CIGS solar thin film cell chamber waste material and carrying out crushing, fine grinding, and carrying out ammonia leaching with a certain mass concentration of ammonia-containing solution as a leaching agent, and the ammonia concentration is 150g / L (in the form of NH 3 The solid-liquid ratio before leaching is 1:10g / mL, the leaching temperature is 60°C, and the leaching time is 3h. After the leaching is completed, ammonia leaching solution and ammonia leaching residue are obtained through liquid-solid separation; after ammonia leaching solution extraction and electrowinning Electrolytic copper can be obtained; the ammonia leaching residue uses NaOH solution with a mass concentration of 50% as the leaching agent to perform alkaline leaching under pressure. The leaching temperature of the alkaline leaching process is 90 ° C, the leaching time is 3 hours, and the solid-liquid ratio before leaching is 1. : 5g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com