Method for recovering valuable metals from waste copper indium gallium selenide battery chips

A technology of copper indium gallium selenide and valuable metals, which is applied in the field of secondary utilization of resources, can solve problems such as high production cost, incomplete separation, complicated and dangerous operation, achieve high-efficiency selective leaching, meet environmental protection requirements, and simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

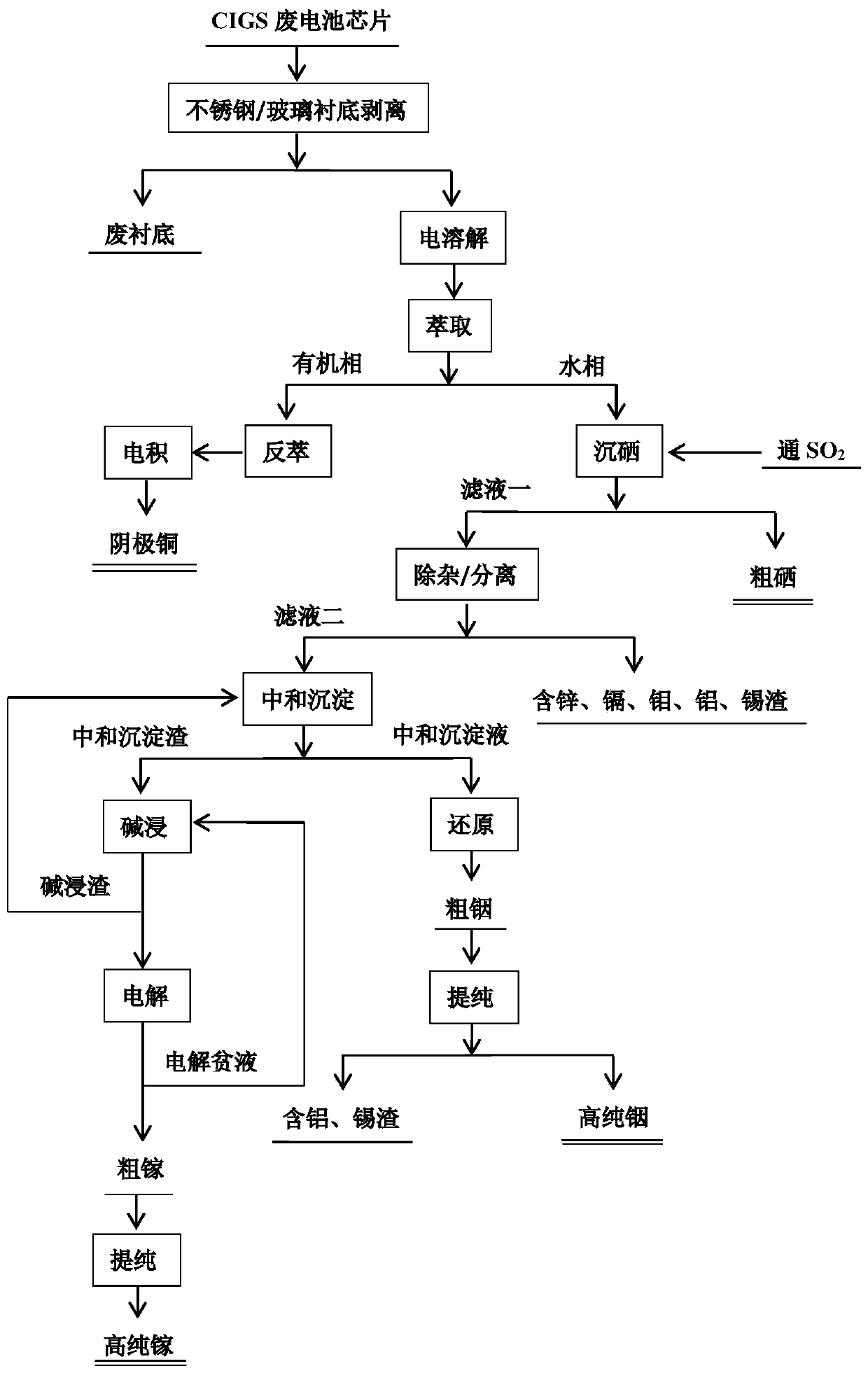

[0045] like figure 1As shown, the implementation steps of this embodiment include: taking 50g of CIGS waste battery chips and peeling off the substrate, using the peeled valuable metal layer as an anode, and under the action of a DC power supply, controlling the voltage of the electrolyzer to 3.0V. Under the acidic condition of 50g / L sulfuric acid, all the waste battery chips are dissolved to obtain a mixed solution; the mixed solution is extracted with an extractant, and the organic phase and the aqueous phase are separated after extraction; Obtain copper cathode; pass SO into the water phase 2 , the flux is SO 2 The ratio of the amount of the substance to the amount of the Se substance in the raw material is 1.5mol / mol, which can be reduced to obtain crude selenium with a purity greater than 98%, and the filtrate is obtained after filtration; the filtrate is removed / separated to obtain zinc, cadmium, molybdenum, aluminum , tin slag and new filtrate; use a certain mass conc...

Embodiment 2

[0047] The implementation steps of this embodiment include: taking 100g of CIGS waste battery chips and peeling off the substrate, using the peeled valuable metal layer as an anode, under the action of a DC power supply, controlling the voltage of the electrolyzer to 1.5V, and when the acidity is 300g / Under the acidic conditions of L sulfuric acid, all the waste battery chips are dissolved to obtain a mixed solution; the mixed solution is extracted with an extractant, and the organic phase and the aqueous phase are separated after extraction; the organic phase can be stripped and electrolytically deposited to obtain cathode copper ; Feed SO into the water phase 2 , the flux is SO 2 The ratio of the amount of the substance to the amount of the Se substance in the raw material is 1.0mol / mol, which can be reduced to obtain crude selenium with a purity greater than 98%, and the filtrate is obtained after filtration; the filtrate is removed / separated to obtain zinc, cadmium, molyb...

Embodiment 3

[0049] The implementation steps of this embodiment include: taking 50g of CIGS waste battery chips and peeling off the substrate, using the peeled valuable metal layer as an anode, under the action of a DC power supply, controlling the voltage of the electrolyzer to 2.0V, and when the acidity is 200g / Under the acidic conditions of L sulfuric acid, all the waste battery chips are dissolved to obtain a mixed solution; the mixed solution is extracted with an extractant, and the organic phase and the aqueous phase are separated after extraction; the organic phase can be stripped and electrolytically deposited to obtain cathode copper ; Feed SO into the water phase 2 , the flux is SO 2 The ratio of the amount of the substance to the amount of the Se substance in the raw material is 1.2mol / mol, which can be reduced to obtain crude selenium with a purity greater than 98%, and the filtrate is obtained after filtration; the filtrate is removed / separated to obtain , tin slag and new f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com