A method for selectively extracting valuable metals in nickel sulfide concentrate at low temperature and atmospheric pressure

A nickel sulfide concentrate, low temperature and normal pressure technology, applied in the field of nickel sulfide concentrate extraction nickel, can solve the problems of environmental pollution, high energy consumption, long recovery and treatment process, etc., and achieves low equipment investment, good selectivity, and resource utilization. Take advantage of the reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

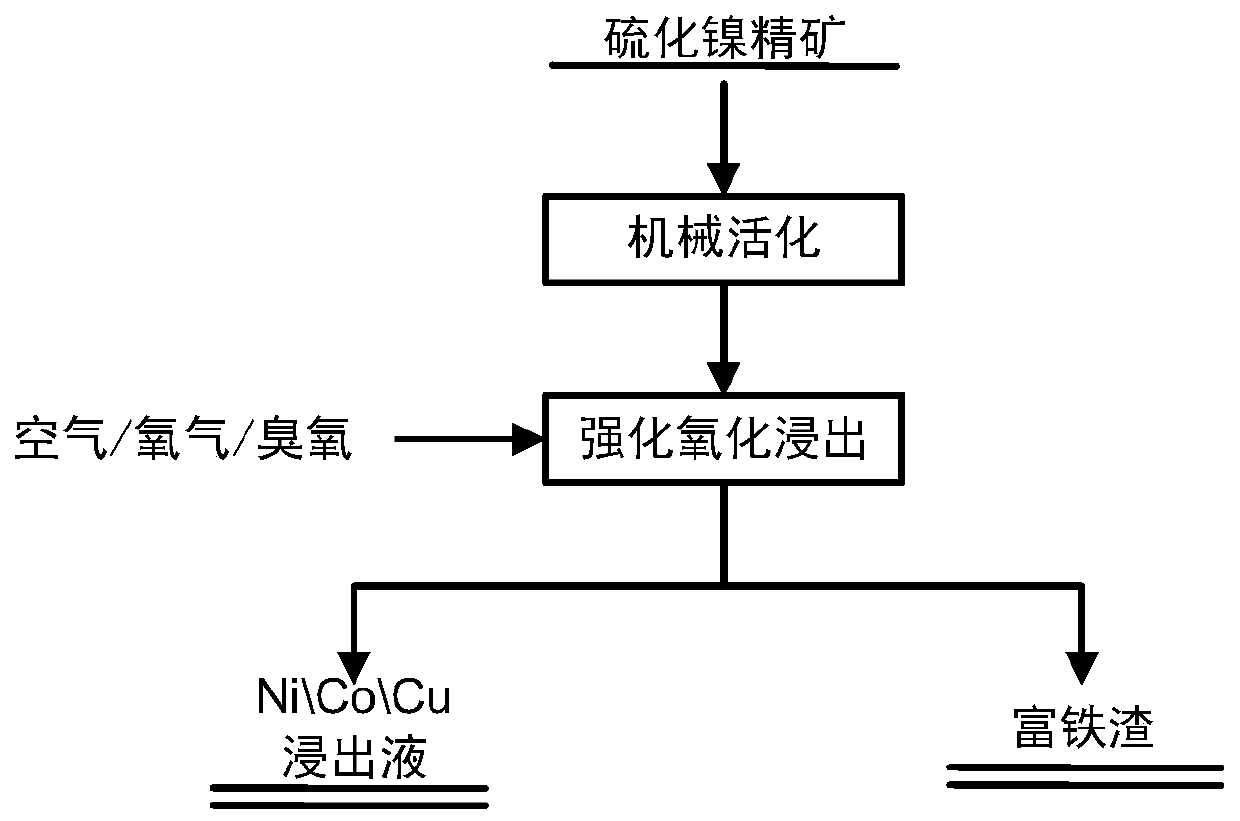

[0028] Such as figure 1 The flow shown is a method for selectively extracting valuable metals in nickel sulfide concentrate at low temperature and normal pressure, and the method includes the following steps:

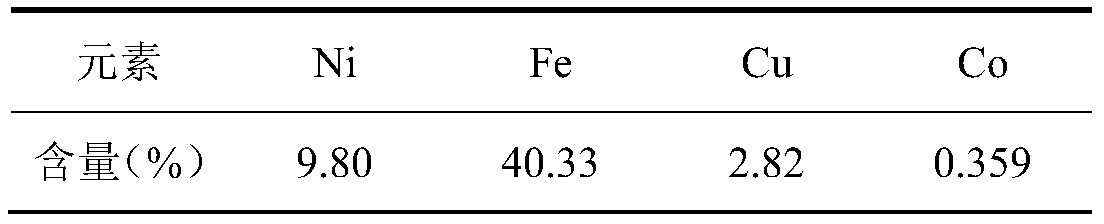

[0029] (1) The nickel sulfide ore used in the experiment is nickel sulfide concentrate after flotation, and its composition is shown in Table 1.1. The nickel sulfide concentrate and balls are mixed according to the ball-to-material ratio of 5:1g / g, and then placed in a high-energy ball mill for mechanical activation. The ball mill speed is 1000rpm, and the ball milling time is 15min. After ball milling, the balls are separated to obtain pre-activated vulcanization. nickel concentrate;

[0030] Table 1.1 Element analysis of nickel sulfide concentrate

[0031]

[0032] (2) Add the nickel sulfide concentrate obtained in step (1) into 2mol / L ammonium sulfate aqueous solution, at a reaction temperature of 100°C, a liquid-solid ratio of 3:1L / g, a rotating speed of 600rpm...

Embodiment 2

[0034] Such as figure 1 The flow shown is a method for selectively extracting valuable metals in nickel sulfide concentrate at low temperature and normal pressure, and the method includes the following steps:

[0035] (1) The nickel sulfide ore used in the experiment is nickel sulfide concentrate after flotation, and its composition is shown in Table 1.1. The nickel sulfide concentrate and balls are mixed according to the ball-to-material ratio of 40:1g / g, and then placed in a high-energy ball mill for mechanical activation. The ball mill speed is 200rpm, and the ball milling time is 240min. After the ball milling, the balls are separated to obtain pre-activated vulcanization. nickel concentrate;

[0036] (2) Add the nickel sulfide concentrate obtained in step (1) into the potassium sulfate solution of 0.5mol / L sulfuric acid and 1mol / L, the reaction temperature is 100°C, the liquid-solid ratio is 3:1L / g, and the rotating speed is 600rpm, air aeration flow rate of 1kg activat...

Embodiment 3

[0038] Such as figure 1 The flow shown is a method for selectively extracting valuable metals in nickel sulfide concentrate at low temperature and normal pressure, and the method includes the following steps:

[0039] (1) The nickel sulfide ore used in the experiment is nickel sulfide concentrate after flotation, and its composition is shown in Table 1.1. The nickel sulfide concentrate and balls are mixed according to the ball-to-material ratio of 5:1g / g, and then placed in a high-energy ball mill for mechanical activation. The ball mill speed is 1000rpm, and the ball milling time is 15min. After ball milling, the balls are separated to obtain pre-activated vulcanization. nickel concentrate;

[0040](2) the nickel sulfide concentrate that step (1) obtains is joined in 0.5mol / L nitric acid solution, is 100 ℃ at reaction temperature, and liquid-solid ratio is 100:1L / g, and rotating speed is 100rpm, and ozone aeration flow rate is Under the condition of 0.05L / min, the microbubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com