Manufacturing method and testing method of piezoelectric ceramic sensor for concrete ERT imaging

A technology of piezoelectric ceramics and a manufacturing method, which is applied to instruments, measuring devices, scientific instruments, etc., can solve the problems of affecting the sending and receiving angle, inconvenient adjustment, low strength, etc., to avoid interference, good durability, and good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

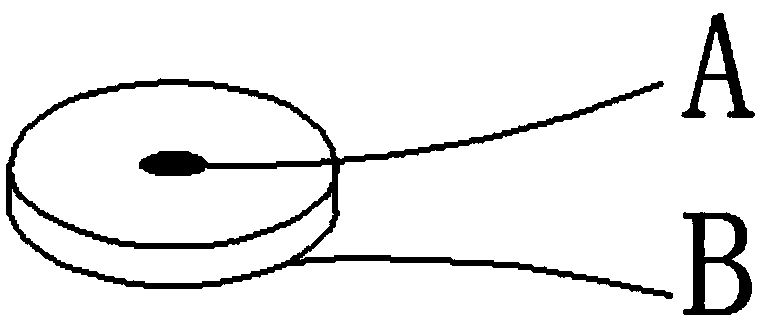

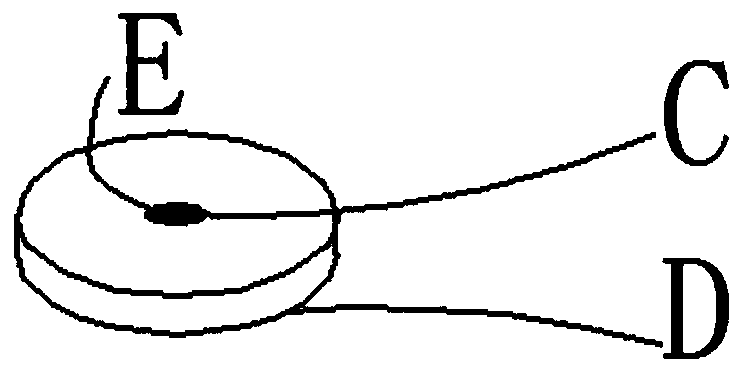

[0044] In the present invention, the piezoelectric ceramic sheet is respectively used for the signal driver and the signal sensor. The signal driver should use the piezoelectric ceramic sheet as PZT-4, and the signal sensor should use the piezoelectric ceramic sheet as PZT-4. The PZT-4 and PZT-4 piezoelectric elements used in this study were produced by Baoding Bofa Sensor Sales Co., Ltd. PZT-4 and PZT-4 are respectively used as receiving drive elements and emitting drive elements to prepare receiving piezoelectric ceramic sensors and emitting piezoelectric ceramic sensors.

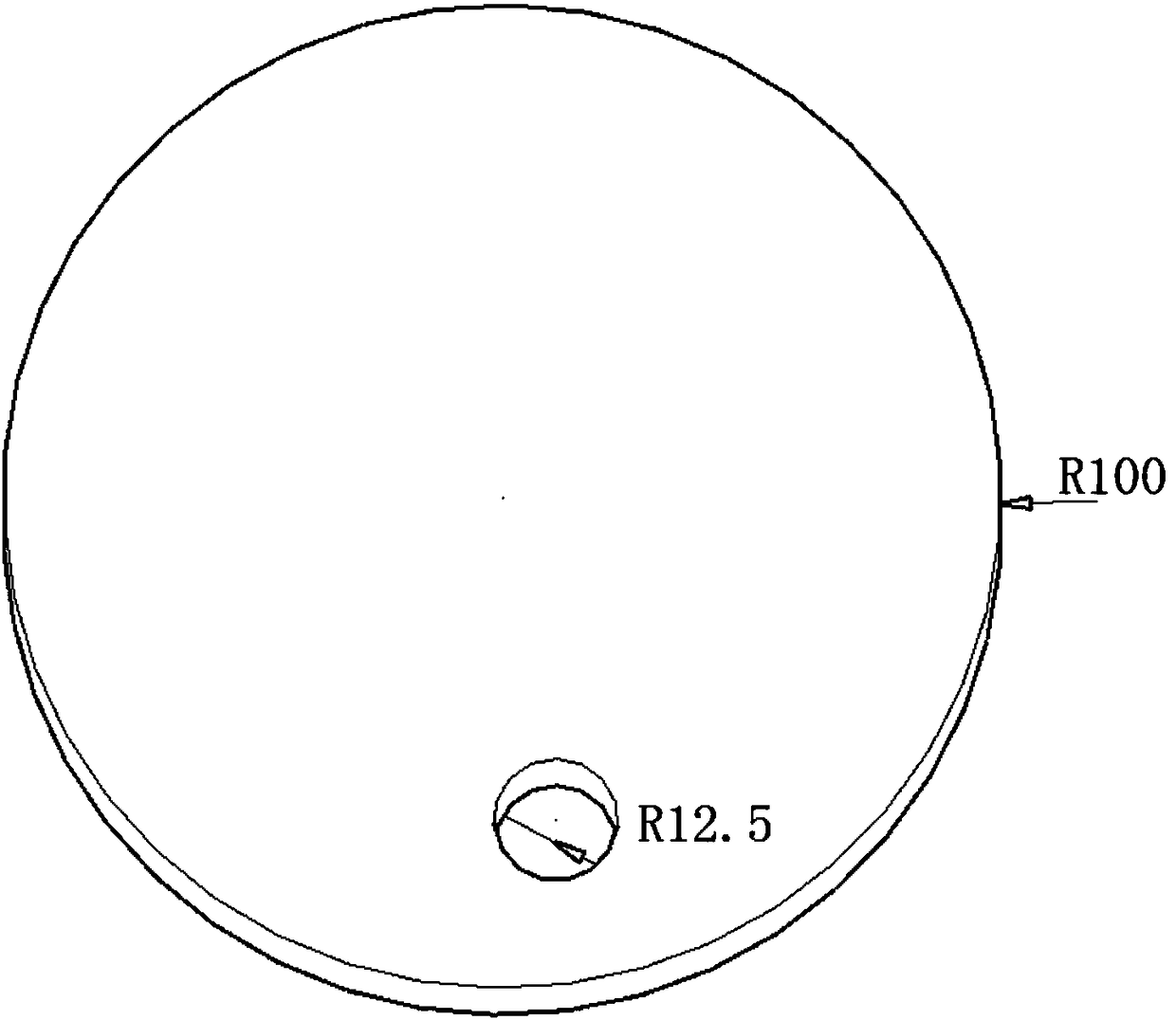

[0045] In the present invention, a piezoelectric ceramic sheet with a diameter of 10mm and a thickness of 1mm is selected. The positive and negative electrodes of the piezoelectric ceramic sheet are respectively located at the positive and negative poles, and the surface with red dots is the positive electrode. Wipe the surface of the sensor with a cotton swab dipped in acetone reagent or absolute alcohol...

Embodiment 2

[0051] In the present invention, the piezoelectric ceramic sheet is used for the signal driver and the signal sensor respectively. The signal driver should use the piezoelectric ceramic sheet as PZT-4, and the signal sensor should use the piezoelectric ceramic sheet as PZT-5. The PZT-4 and PZT-5 piezoelectric elements used in this study were produced by Baoding Bofa Sensor Sales Co., Ltd. PZT-4 and PZT-5 are respectively used as receiving drive elements and emitting drive elements to prepare receiving piezoelectric ceramic sensors and emitting piezoelectric ceramic sensors.

[0052] The silicone resin includes 95 parts of epoxy resin, 20 parts of toluene solvent, 60 parts of polytetrafluoroethylene filling powder, and 2 parts of epoxy resin curing agent; bake the encapsulated piezoelectric ceramic sensor at 60°C , and keep it warm for 20 hours to cure the epoxy resin and reach a hardness of 12MPa.

[0053] The packaging material is 12 parts of cement, 0.9 part of epoxy resin,...

Embodiment 3

[0057] In the present invention, the piezoelectric ceramic sheet is respectively used for the signal driver and the signal sensor. The signal driver should use the piezoelectric ceramic sheet model PZT-5, and the signal sensor should use the piezoelectric ceramic sheet model PZT-5. The PZT-5 and PZT-5 piezoelectric elements used in this study were produced by Baoding Bofa Sensor Sales Co., Ltd. PZT-5 and PZT-5 are respectively used as the receiving drive element and the transmitting drive element to prepare the receiving piezoelectric ceramic sensor and the emitting piezoelectric ceramic sensor.

[0058] The silicone resin includes 110 parts of epoxy resin, 30 parts of toluene solvent, 70 parts of polytetrafluoroethylene filling powder, and 3 parts of epoxy resin curing agent; bake the encapsulated piezoelectric ceramic sensor at 60 °C , and keep it warm for 20 hours to cure the epoxy resin and reach a hardness of 16MPa.

[0059] The packaging material is 13 parts of cement, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com