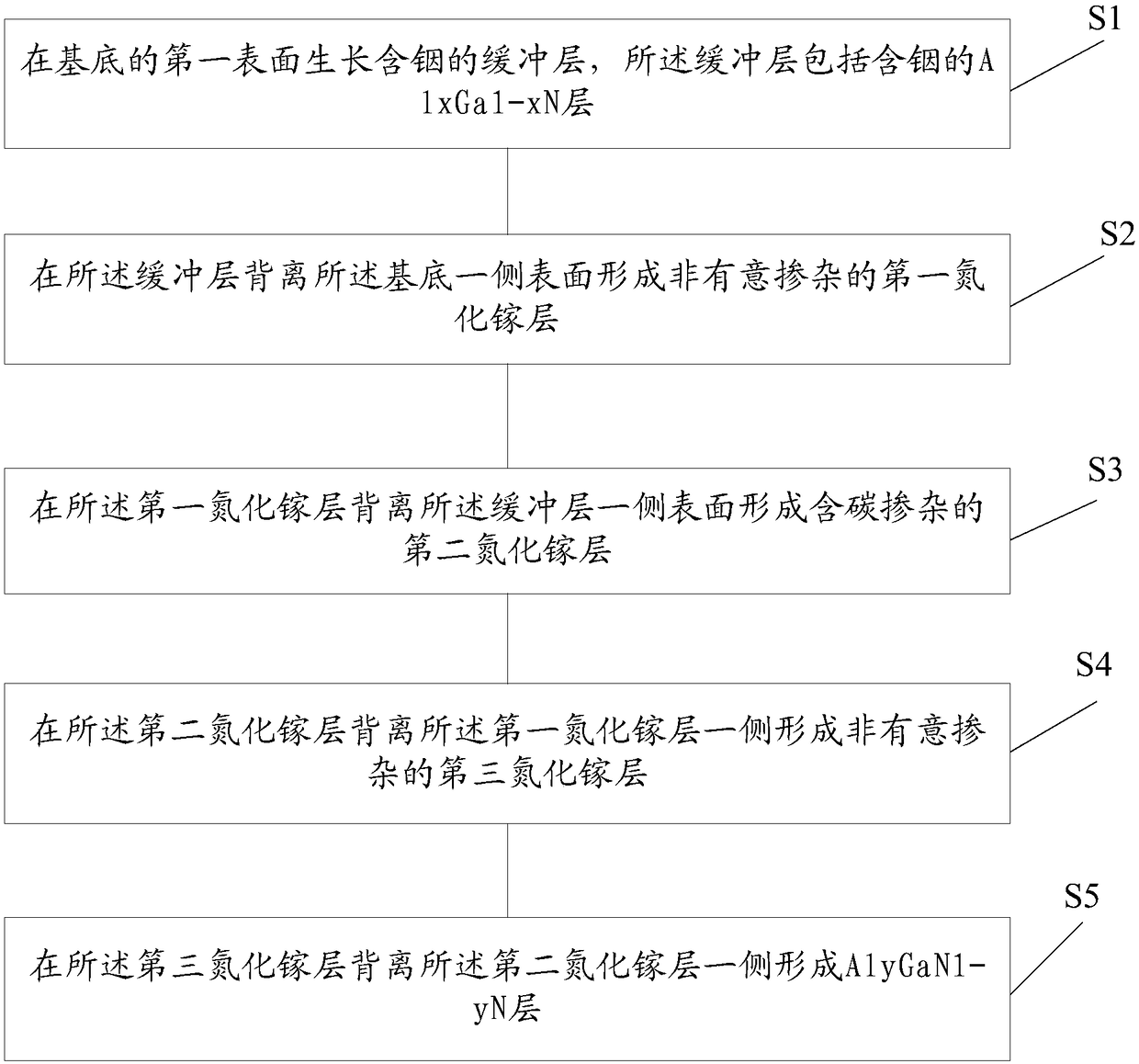

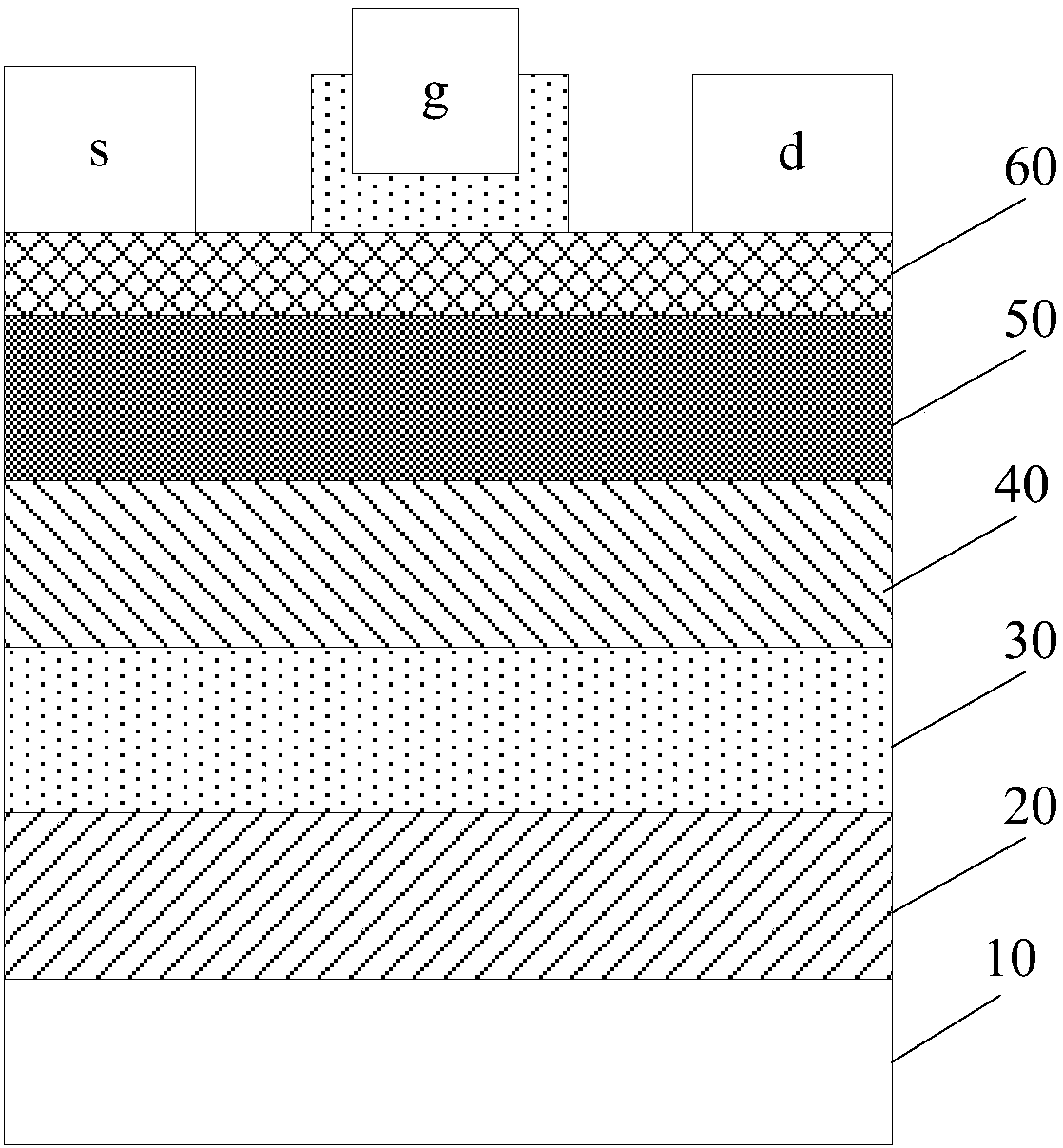

Gallium nitride semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as low breakdown voltage, achieve the effects of increasing breakdown voltage, improving performance, and improving relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] As mentioned in the background section, the breakdown voltage of existing gallium nitride semiconductor devices is relatively low.

[0054] The inventors found that this is because the existing gallium nitride semiconductor devices need to be grown using heterogeneous substrates such as sapphire or silicon, that is, gallium nitride is grown on a silicon substrate or a sapphire substrate, while a silicon substrate or a sapphire substrate and nitrogen The lattice constant of gallium nitride has a large difference. For example, the lattice constant of silicon substrate and gallium nitride has a difference of about 17%. A large number of defects are generated to form a leakage path, and gallium nitride has N-type characteristics due to its own nitrogen holes during the growth process, resulting in a low breakdown voltage of gallium nitride semiconductor devices.

[0055] In addition, since the thermal expansion coefficient of silicon substrate or sapphire substrate and gall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com