Thulium-doped microsphere cavity laser and preparation method thereof

A laser and microsphere cavity technology, applied in the field of micro-optical devices, can solve the problems of the laser performance of semiconductor lasers that are greatly affected by temperature, the beam divergence angle is large, the directionality, monochromaticity and coherence are not ideal, etc., and achieve laser output. Stable, high quality factor, easy to create effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

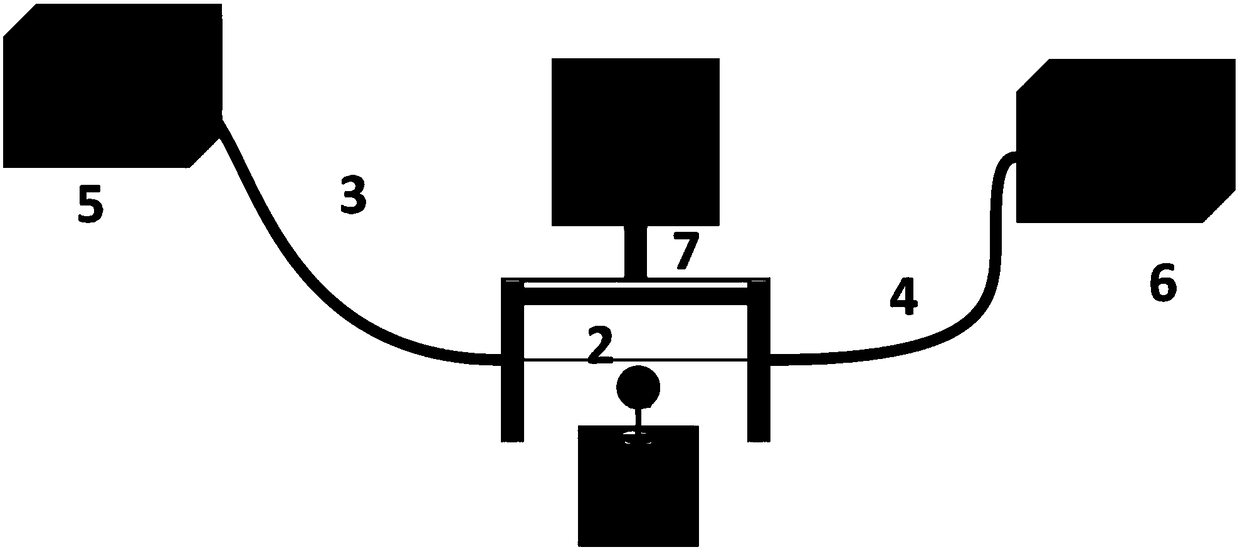

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

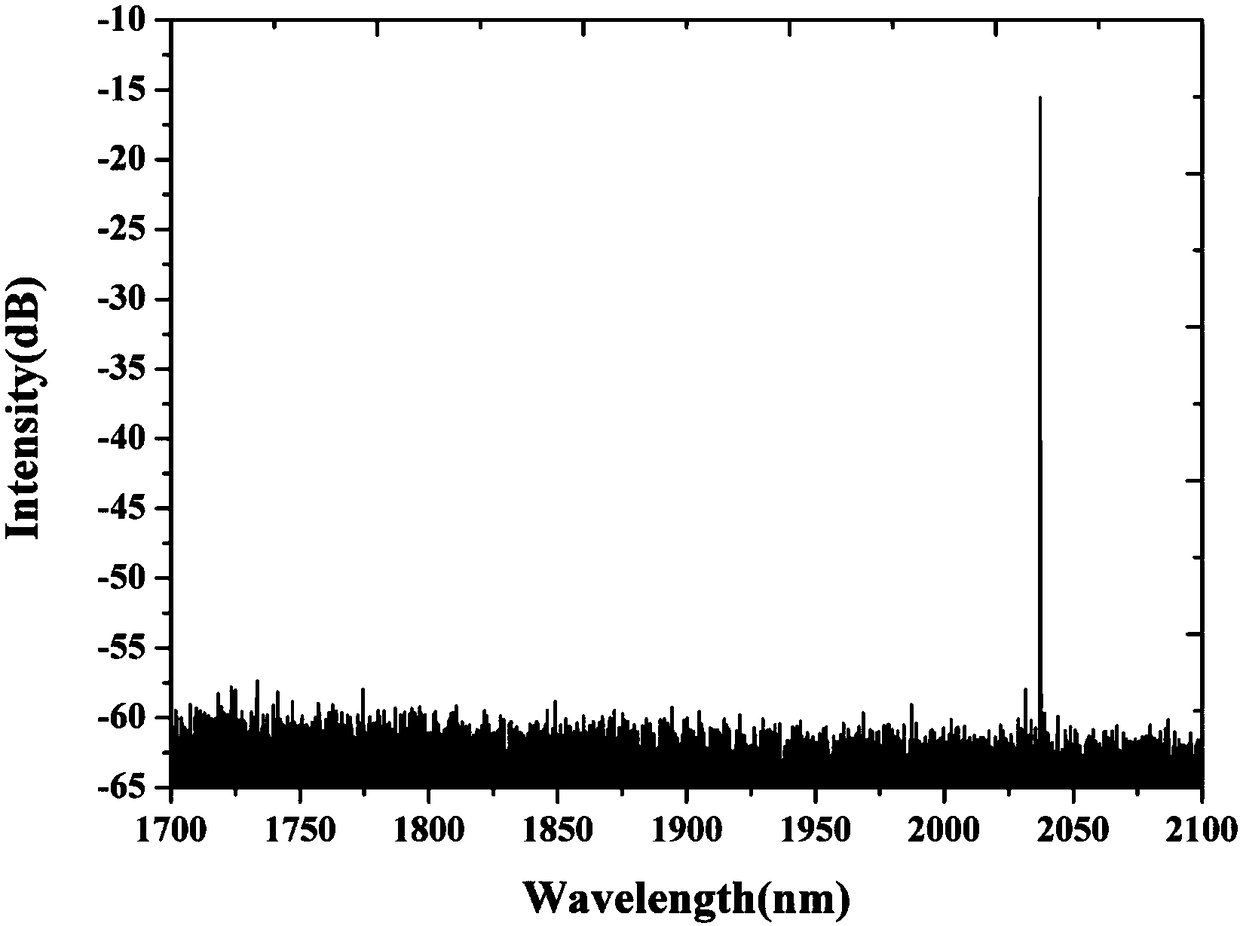

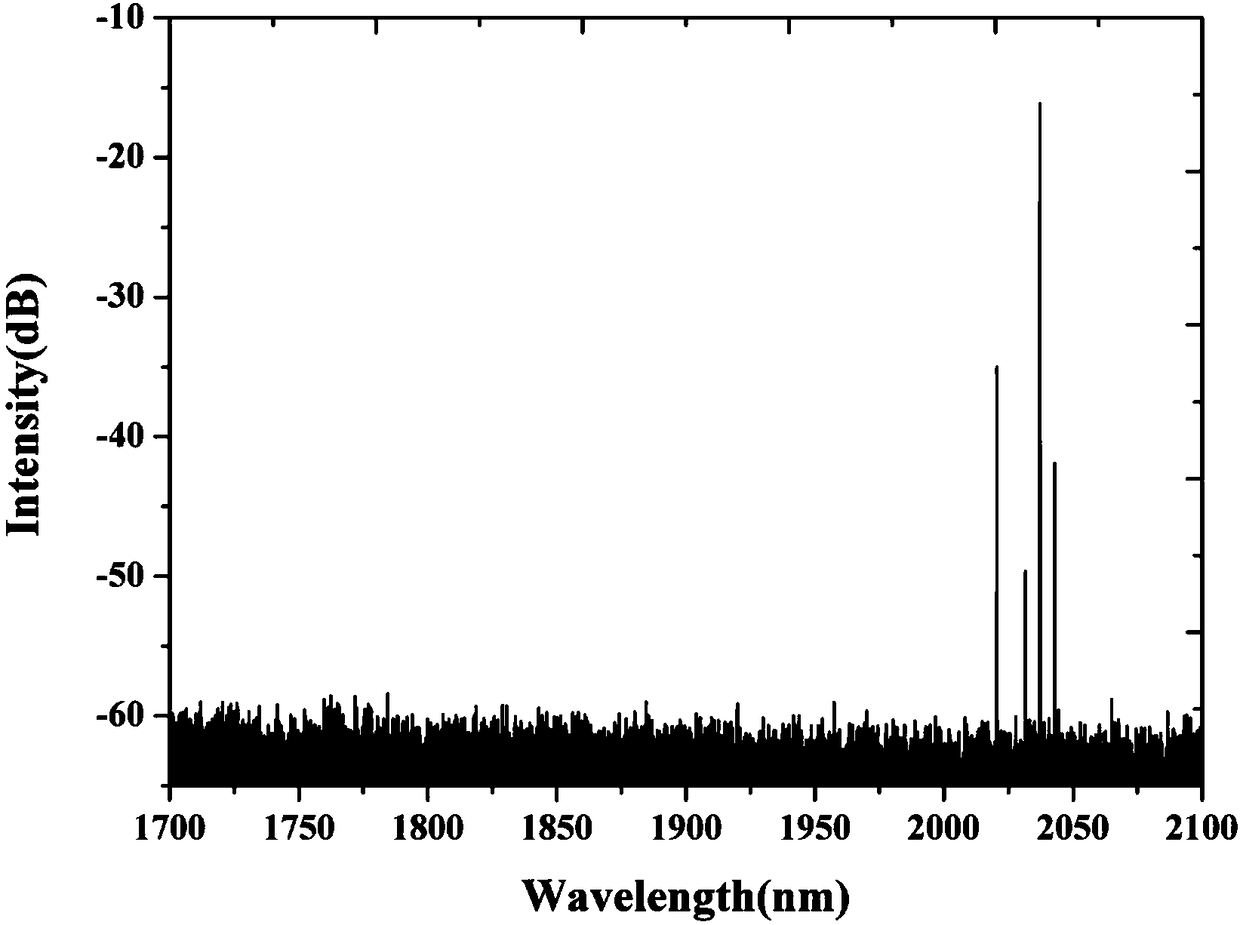

[0018] A thulium-doped microsphere cavity laser, consisting of microspheres doped with thulium ions coupled to a tapered fiber; the pump light source is 808nm laser, coupled with a tapered fiber to thulium-doped microspheres; a 2μm laser is output from the other end of the tapered fiber .

[0019] A method for preparing a thulium-doped microsphere cavity laser, comprising the following steps:

[0020] (1) prepare the solution containing thulium ion by sol-gel method;

[0021] (2) Immerse the end of the communication optical fiber with the coating removed in a solution containing thulium ions to make the solution adhere to the optical fiber, and then heat and melt the end of the optical fiber with a carbon dioxide laser; the end of the optical fiber forms a very smooth and very spherical microsphere, Immerse the microspheres again in the solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com