A kind of preparation method of bimetallic PT-BI catalyst and a kind of method of selective catalytic oxidation glycerol to DHA

A catalytic oxidation and catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, organic compound preparation, catalyst regeneration/reactivation, etc., can solve the problem of reducing glycerin conversion rate and product selectivity, Pt catalyst loss In order to achieve the effect of high DHA selectivity, simple preparation method and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

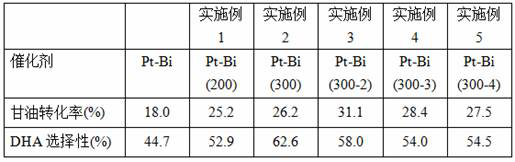

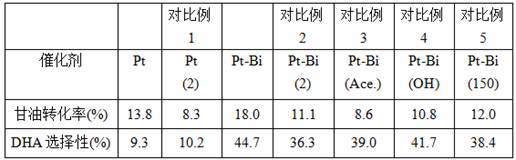

Embodiment 1

[0055] (1) Catalytic oxidation of glycerol to 1,3-dihydroxyacetone

[0056] In the four-necked flask of 150mL, add aqueous glycerol (50 g, 10wt.%, Bi (m Bi / m Pt = 0.2)) and 100mg of Pt catalyst to form an in-situ bimetallic Pt-Bi catalyst, the temperature was raised to 60°C at a stirring rate of 600 rpm, and then oxygen (150 mL / min) was introduced to start the reaction; after 6h, the reaction was stopped. The mixture of the reaction solution and the catalyst in the reactor must be weighed before and after the reaction, and then the liquid-solid phase mixture is filtered; the reaction liquid is detected and analyzed by liquid chromatography.

[0057] (2) Regeneration of bimetallic Pt-Bi catalyst

[0058] The bimetallic Pt-Bi catalyst reacted in (1) was filtered, washed with water and alcohol, dried in vacuum, ground, put into a porcelain boat, placed in a horizontal high-temperature tube furnace for calcination, and the calcination condition was a temperature of 200 °C, A...

Embodiment 2

[0060] The difference between this example and Example 1 is that the calcination temperature in (2) is 300° C.; the others are the same as Example 1; the obtained catalyst is marked as Pt-Bi(300).

Embodiment 3

[0062] The Pt-Bi(300) prepared in Example 2 was recycled once, that is, steps (1) and (2) were repeated, and the obtained catalyst was marked as Pt-Bi(300-2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com