Rare earth modified ethylbenzene dealkylation catalyst and preparation method thereof

A technology of ethylbenzene dealkylation and rare earth modification, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of long catalyst preparation process and high cost, and achieve high ethylbenzene conversion activity and p-xylene selectivity, improved activity, timely effect of reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

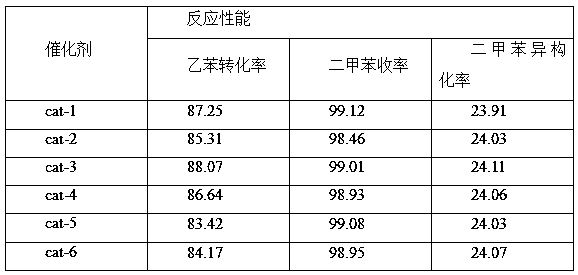

Embodiment 1

[0023] First, modify the EUO molecular sieve and ZSM-5 molecular sieve: prepare a lanthanum acetate solution with a concentration of 0.05mol / L with deionized water, and mix the EUO molecular sieve or ZSM-5 molecular sieve with the lanthanum acetate solution at a solid-to-liquid ratio of 1:5 , impregnated and exchanged at 80°C, then dried at 120°C for 12 hours, and calcined at 500°C to obtain a lanthanum-modified EUO or ZSM-5 molecular sieve catalyst.

[0024] Take 20kg of the prepared rare earth lanthanum modified EUO molecular sieve, 50kg of rare earth lanthanum modified ZSM-5 molecular sieve, and 30kg of alumina powder, and fully mix them. Add 40% of the total mass of the powder with a weight concentration of 2.0% nitric acid aqueous solution and knead, extrude into a cylindrical strip with a diameter of 2.0 mm, dry at 120° C. for 5 hours, and roast at 550° C. in air for 6 hours to obtain a catalyst carrier.

[0025] Get 50 grams of the prepared catalyst carrier, join in 200...

Embodiment 2

[0028] First, EUO molecular sieve and ZSM-5 molecular sieve are modified: the modification method is the same as in Example 1, 20 kg of prepared rare earth lanthanum modified EUO molecular sieve, 50 kg of rare earth lanthanum modified ZSM-5 molecular sieve, alumina powder 30kg, fully mixed. Add 40% of the total mass of the powder with a weight concentration of 2.0% nitric acid aqueous solution and knead, extrude into a cylindrical strip with a diameter of 2.0 mm, dry at 120° C. for 5 hours, and roast at 550° C. in air for 6 hours to obtain a catalyst carrier.

[0029] Take 50 grams of the prepared carrier, add it to 200 milliliters of impregnation solution containing 0.2 grams of chloroplatinic acid and 2.0 grams of ammonium metatungstate, and dynamically impregnate it for 12 hours at room temperature. Calcined at 550°C for 6 hours to obtain the catalyst, numbered cat-2. The catalyst evaluation method is as in Example 1, and the reaction results are shown in Table 1.

Embodiment 3

[0031] First, modify the EUO molecular sieve and ZSM-5 molecular sieve: prepare a cerium nitrate solution with a concentration of 0.1mol / L with deionized water, and mix the EUO molecular sieve or ZSM-5 molecular sieve with the cerium nitrate solution at a solid-to-liquid ratio of 1:2 , impregnated and exchanged at 60°C, then dried at 120°C for 10 hours, and calcined at 600°C to obtain a cerium-modified EUO or ZSM-5 molecular sieve catalyst.

[0032] Take 40kg of the prepared rare earth cerium-modified EUO molecular sieve, 40kg of rare earth cerium-modified ZSM-5 molecular sieve, and 20kg of alumina powder, and fully mix them. Add 40% of the total mass of the powder with a weight concentration of 5.0% nitric acid aqueous solution and knead, extrude into a cylindrical strip with a diameter of 2.0 mm, dry at 120° C. for 5 hours, and roast at 550° C. in air for 6 hours to obtain a catalyst carrier.

[0033]Take 50 grams of the catalyst carrier, add it to 200 milliliters of an impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com