Agricultural production waste closed aerobic sub-high-temperature microorganism fermentation seven-day fertilizer-making method and device

A microbial fermentation, sub-high temperature technology, applied in fertilization equipment, agriculture, animal carcass fertilizer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

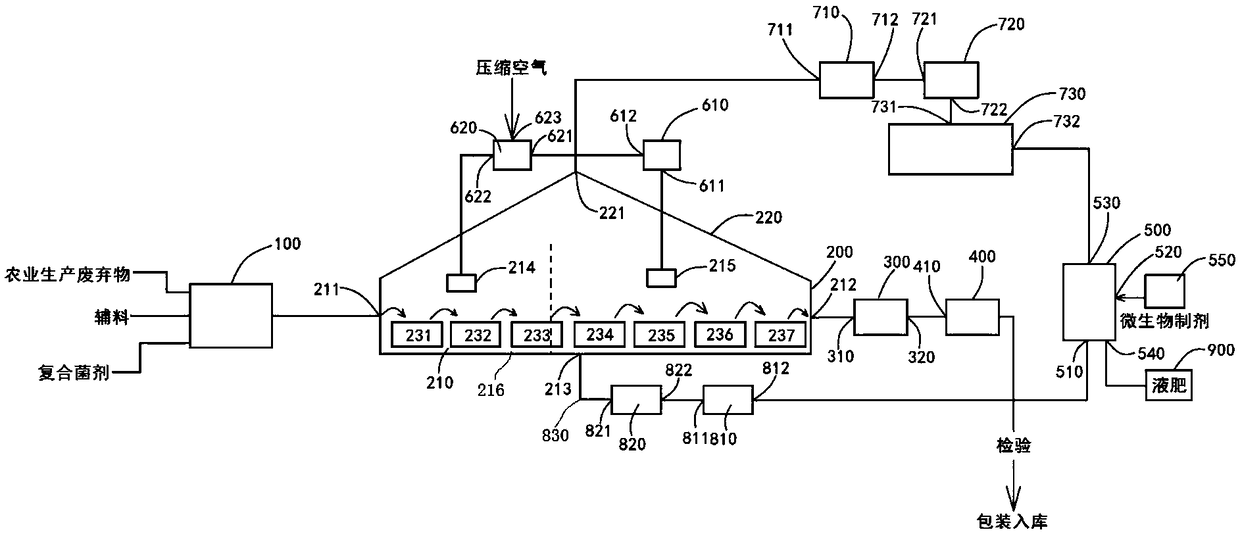

[0060] see figure 1 , shown in the figure is a closed aerobic sub-high temperature microbial fermentation fertilizer plant for seven days of agricultural production waste, including a batching stirring device 100, a sealed fermentation tank 200, a crushing device 300, an aging device 400, fermentation gas recycling and fresh air Gas distribution system, residual fermentation gas recovery and treatment system, fermentation material leachate and microbial fermentation secretion diversion system, fermentation sequestration device 500.

[0061] The batching stirring device 100 is composed of a batching part (not shown in the figure) and a stirring part (not shown in the figure). The predetermined formula quantity is matched with the mixed material, and the mixed part is randomly input. docking with the stirring part;

[0062] The mixing part is a double-shaft knife holder counter-rotating horizontal assembly mixer. The feed inlet of the double-shaft knife rest counter-rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com