A kind of silicone rubber sheet with antistatic heat conduction function and preparation method thereof

A silicone rubber sheet, anti-static technology, applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problem of only focusing on thermal conductivity, ignoring the anti-static ability of products, etc., to improve anti-static ability, reduce harmfulness, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

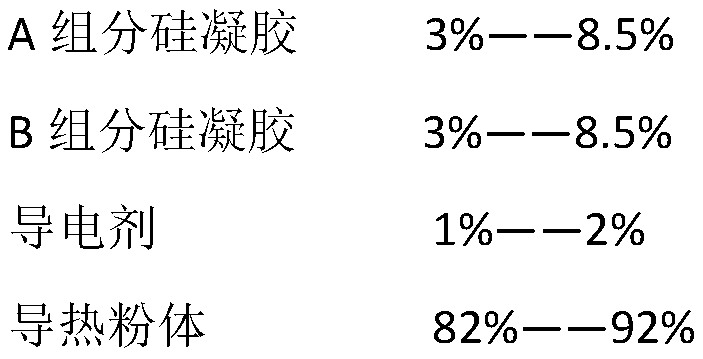

[0029] A method for preparing a silicone rubber sheet with antistatic and heat conduction functions is prepared according to the following steps:

[0030] (1) Add to 50g of liquid silicone gel component A to meet the conditions (according to the GB / T-24521-2009 standard test, the volume resistivity of the conductive agent powder is ≤10 under the pressure of 20-30MPa -3 Ω·cm) conductive agent conductive carbon black powder 5.6g, use 500W power to ultrasonically disperse for 0.5 hours; add 5.6g of conductive agent conductive carbon black powder that meets the conditions to 50g liquid silicone gel B component, use 500W power to ultrasonically disperse 0.5 hours.

[0031] (2) Select 150g of magnesium oxide powder with a sheet diameter of 2μm, 375g of α-spherical alumina with a particle size of 90μm, and 225g of α-spherical alumina with a particle size of 45μm for compound mixing, and then add it to 300ml to dissolve 1g of A174 In the 95% ethanol solution of the joint agent, use a...

Embodiment 2

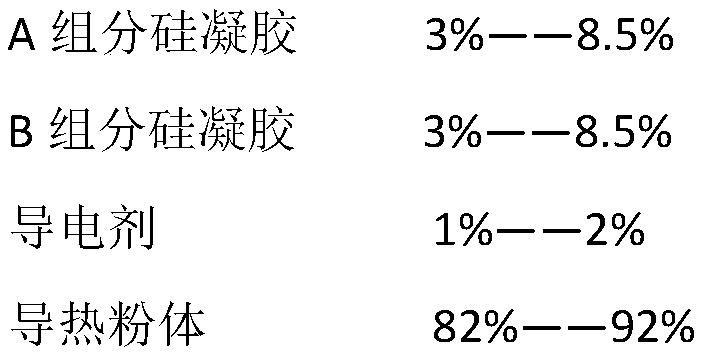

[0035] A method for preparing a silicone rubber sheet with antistatic and heat conduction functions is prepared according to the following steps:

[0036] (1) Add to 50g of liquid silicone gel component A to meet the conditions (according to the GB / T-24521-2009 standard test, the volume resistivity of the conductive agent powder is ≤10 under the pressure of 20-30MPa -3 Ω cm) conductive agent graphene powder 5.6g, use 1000W power ultrasonic dispersion for 0.5 hours; add 5.6g conductive agent graphene powder meeting the conditions to 50g liquid silicone gel B component, use 1000W power ultrasonic dispersion 0.5 hours.

[0037](2) Select 150g of hexagonal boron nitride powder with a diameter of 2μm, 375g of α-spherical alumina with a particle size of 90μm, and 225g of α-spherical alumina with a particle size of 45μm for compound mixing, and then add it to 300ml to dissolve 1g of KH560 coupling agent in 95% ethanol solution, disperse with high-speed disperser for 2 hours, dry in ...

Embodiment 3

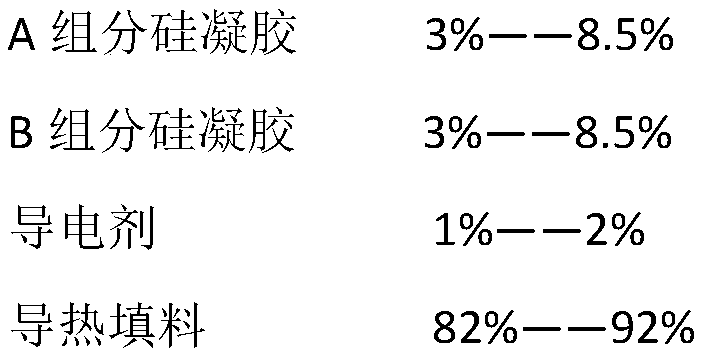

[0041] A method for preparing a silicone rubber sheet with antistatic and heat conduction functions is prepared according to the following steps:

[0042] (1) Add to 50g of liquid silicone gel component A to meet the conditions (according to the GB / T-24521-2009 standard test, the volume resistivity of the conductive agent powder is ≤10 under the pressure of 20-30MPa -3 Ω·cm) conductive agent graphite fiber powder 5.6g, use 800W power to ultrasonically disperse for 0.5 hours; add conductive agent graphite fiber powder 5.6g to 50g liquid silicone gel B component, use 800W power to ultrasonically disperse for 0.5 hours .

[0043] (2) Select 150g of hexagonal boron nitride powder with a diameter of 2μm, 375g of α-spherical alumina with a particle size of 90μm, and 225g of α-spherical alumina with a particle size of 45μm for compound mixing, and then add it to 300ml to dissolve 1g of KH560 coupling agent in 95% ethanol solution, disperse with high-speed disperser for 2 hours, dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com