Wood-plastic-glass painting door

A glass baking varnish and wood-plastic technology, applied to glass/slag layered products, door leaves, fire doors, etc., can solve problems affecting heat insulation, moisture resistance and noise reduction, shortening the service life of baking varnish doors, easy oxidation, warping and falling off, etc. Problems, to achieve the effect of improving heat insulation and sound insulation and noise reduction, improving the effect of pasting and fixing, and improving the moisture-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

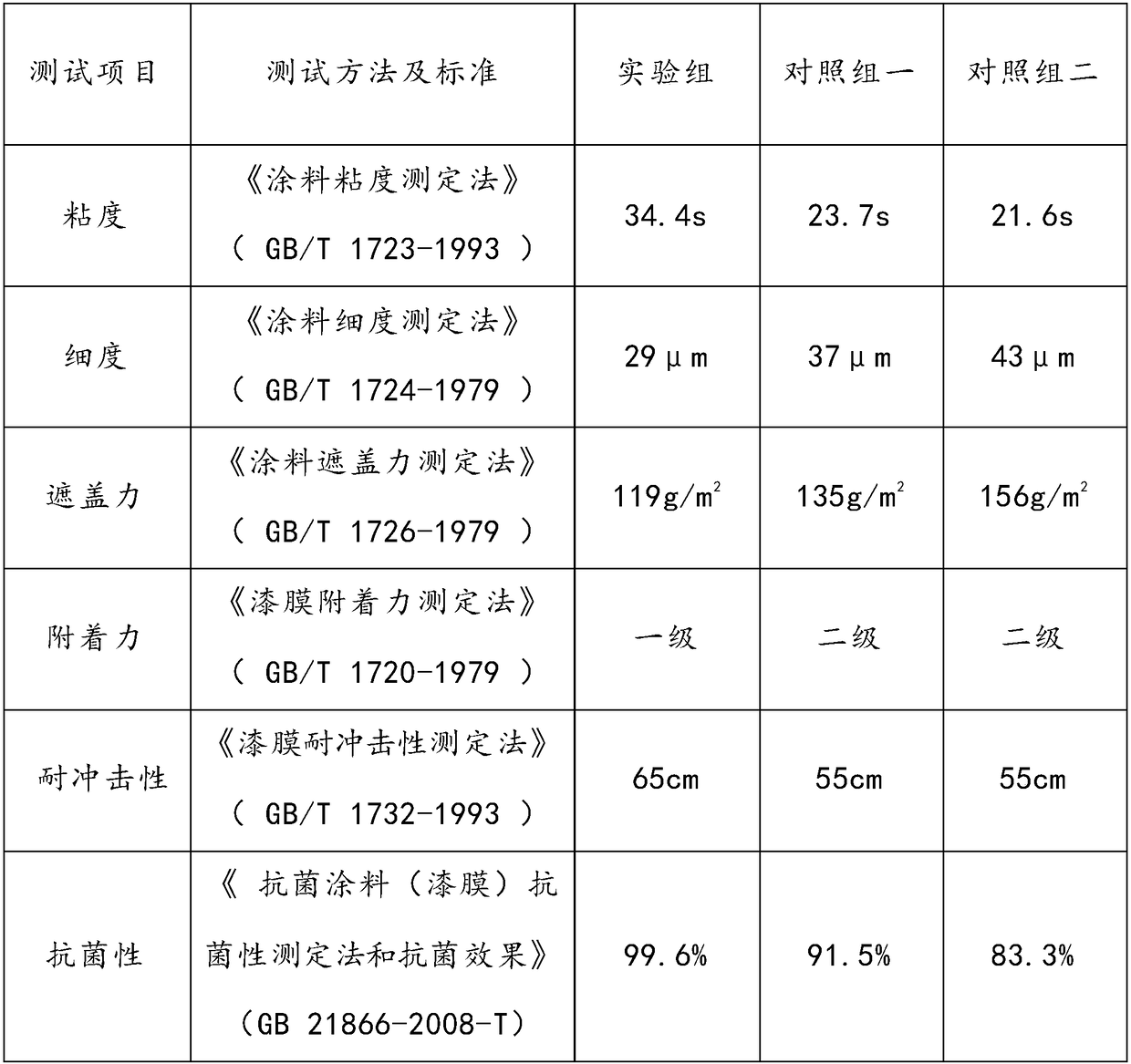

Embodiment 1

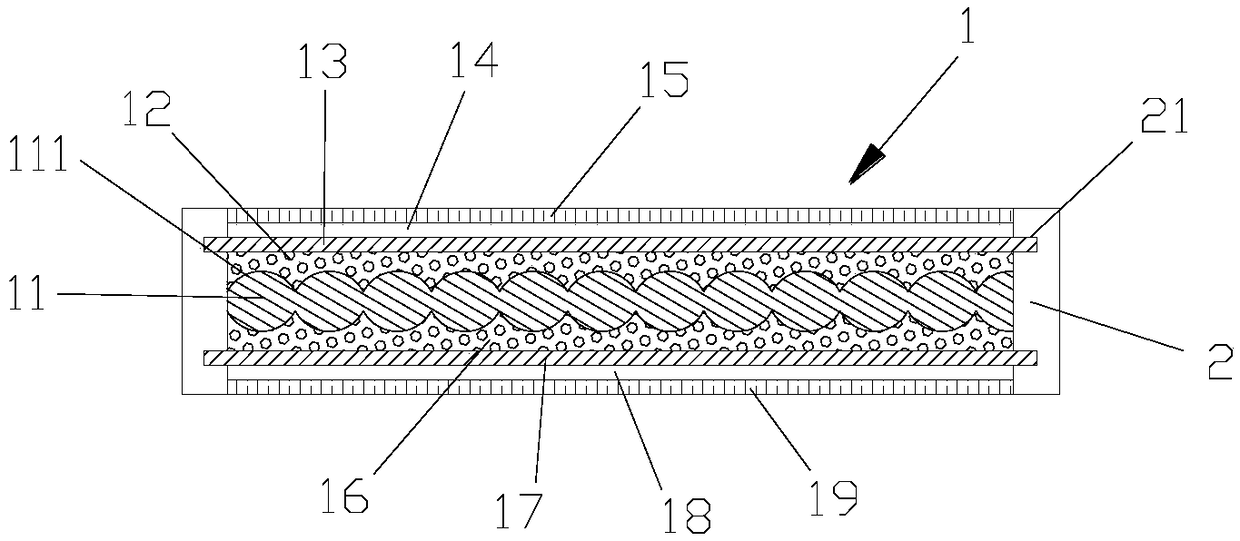

[0027] A wood-plastic glass baking paint door, such as figure 1 As shown, it includes a paint-baking door body 1, and a solid wood frame strip 2 arranged on the side of the paint-baking door body 1 for reinforcing the paint-baking door body 1; The first foam particle layer 12 on one side surface of the board 11 and fixed with the central density board 11 by glue is used for heat insulation and noise reduction, and the first foam particle layer 12 is arranged on the surface of the first foam particle layer 12 and is connected to the first foam particle layer. The foam particle layer 12 is pasted and fixed by glue, the first solid wood board 13 for extruding and fixing the first foam particle layer 12, and the first solid wood board 13 that is arranged on the surface of the first solid wood board 13 and covers the first solid wood board 13. The baking varnish layer 14, and the first glass layer 15 that is arranged on the surface of the first baking varnish layer 14 and fixed wit...

Embodiment 2

[0038] A wood-plastic glass baking paint door, such as figure 1 As shown, it includes a paint-baking door body 1, and a solid wood frame strip 2 arranged on the side of the paint-baking door body 1 for reinforcing the paint-baking door body 1; The first foam particle layer 12 on one side surface of the board 11 and fixed with the central density board 11 by glue is used for heat insulation and noise reduction, and the first foam particle layer 12 is arranged on the surface of the first foam particle layer 12 and is connected to the first foam particle layer. The foam particle layer 12 is pasted and fixed by glue, the first solid wood board 13 for extruding and fixing the first foam particle layer 12, and the first solid wood board 13 that is arranged on the surface of the first solid wood board 13 and covers the first solid wood board 13. The baking varnish layer 14, and the first glass layer 15 that is arranged on the surface of the first baking varnish layer 14 and fixed wit...

Embodiment 3

[0049] A wood-plastic glass baking paint door, such as figure 1 As shown, it includes a paint-baking door body 1, and a solid wood frame strip 2 arranged on the side of the paint-baking door body 1 for reinforcing the paint-baking door body 1; The first foam particle layer 12 on one side surface of the board 11 and fixed with the central density board 11 by glue is used for heat insulation and noise reduction, and the first foam particle layer 12 is arranged on the surface of the first foam particle layer 12 and is connected to the first foam particle layer. The foam particle layer 12 is pasted and fixed by glue, the first solid wood board 13 for extruding and fixing the first foam particle layer 12, and the first solid wood board 13 that is arranged on the surface of the first solid wood board 13 and covers the first solid wood board 13. The baking varnish layer 14, and the first glass layer 15 that is arranged on the surface of the first baking varnish layer 14 and fixed wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com