Seamless coke oven ascension pipe raw gas evaporation cooling device structure

A technology of vaporization cooling and seamless coke oven, which is applied to the safety device of the furnace, the discharge device of dry distillation gas, and the coke oven. It can solve the problems of low service life, low strength, and difficult production, and achieve long service life Good pressure bearing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

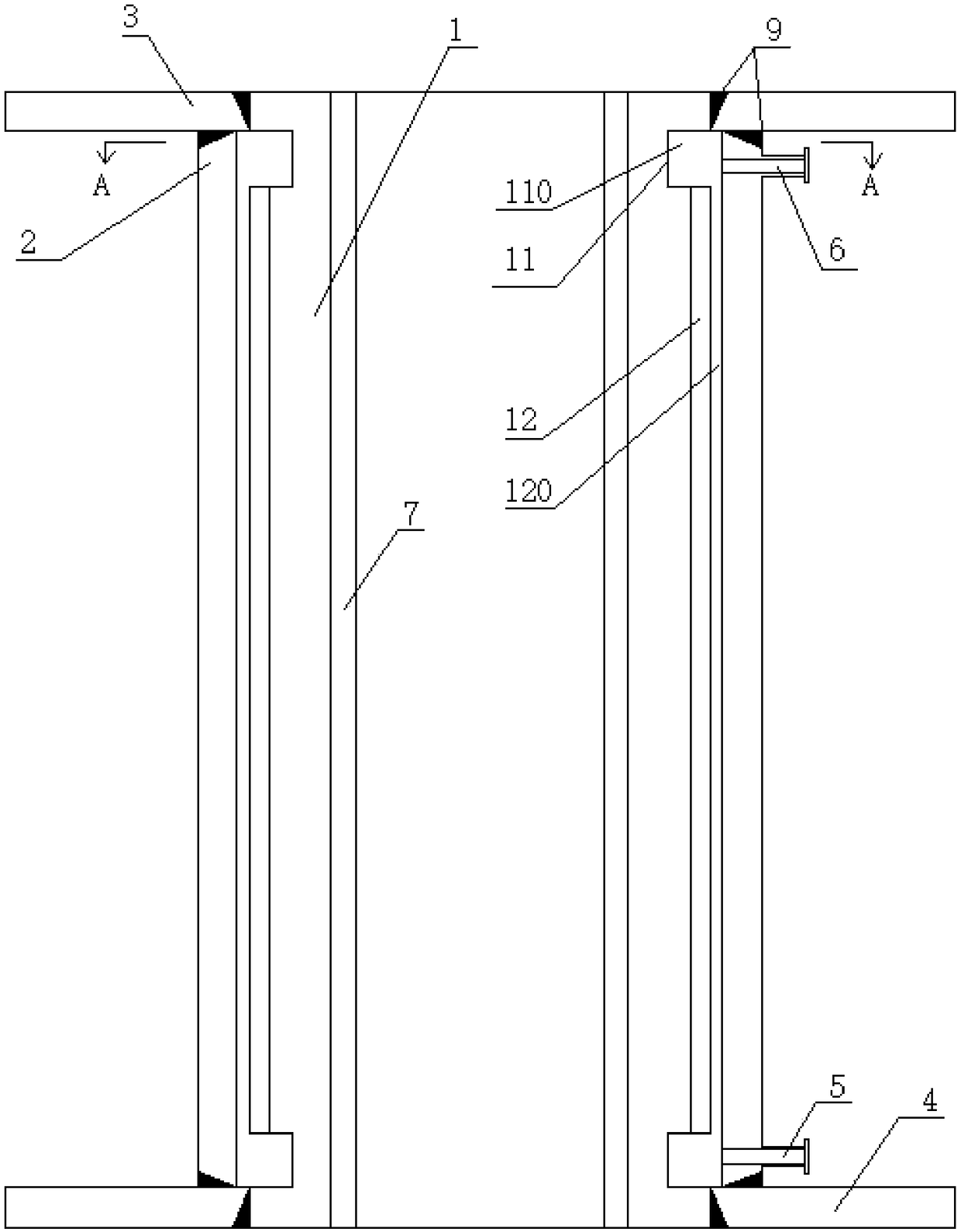

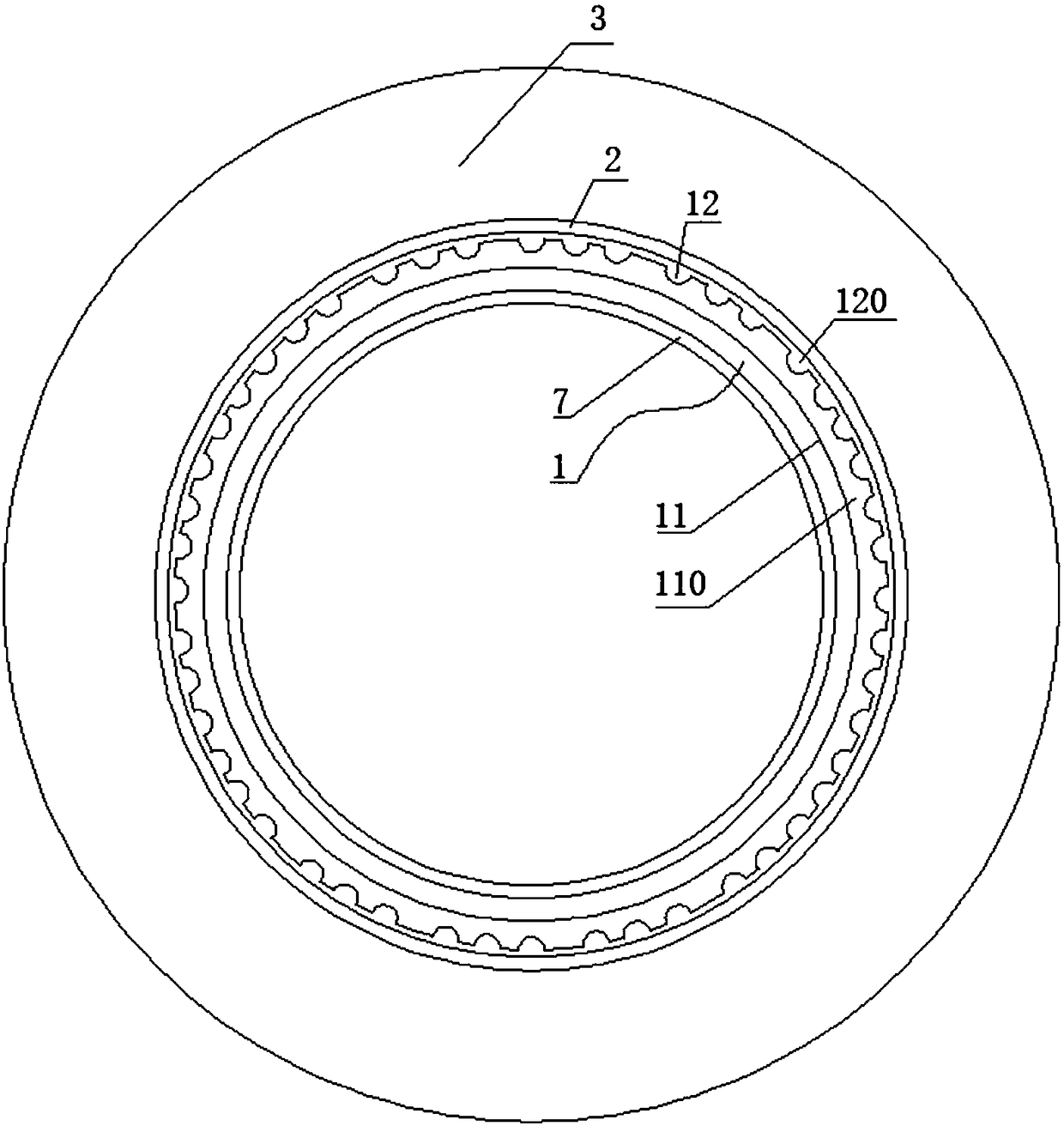

[0033] combine figure 1 and figure 2As shown, the structure of a seamless coke oven riser raw gas vaporization cooling device in this embodiment includes an inner cylinder 1, an outer cylinder 2, an upper flange 3 and a lower flange 4, and the outer cylinder 2 is sleeved on The outer side of the inner cylinder 1, the two ends of the inner cylinder 1 and the outer cylinder 2 are fixedly connected by the upper flange 3 and the lower flange 4 respectively, and a closed water tank is formed between the inner cylinder 1 and the outer cylinder 2 Jacket, the upper flange 3 is welded with the inner cylinder 1 and one end of the outer cylinder 2 through the slit 9, and the lower flange 4 is welded with the other end of the inner cylinder 1 and the outer cylinder 2 through the slit 9. connected to form the main structure of the coke oven riser. The inner cylinder 1 has a certain thickness, and an annular vapor-liquid tank 11 and a vapor-liquid communication groove 12 are formed on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com