Reinforced ni-based wear-resistant laser cladding coating using nb element and preparation method thereof

A laser cladding and elemental technology, which is applied in coating, metal material coating process, etc., can solve the problems of mold steel surface wear and other problems, and achieve the effect of no pollution, simple preparation process and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

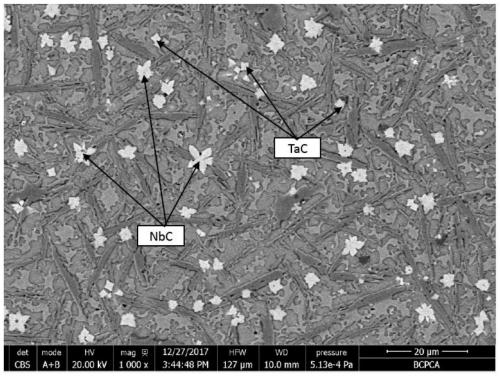

Image

Examples

Embodiment 1

[0023] Example 1: The laser power is 1800W, and the amount of pure Nb powder added is 4.5% of the mass of the nickel-based alloy composite powder.

[0024] (1) Cr12MoV steel substrate pretreatment

[0025] The surface of the processed automobile die steel Cr12MoV steel substrate was polished with sandpaper and cleaned with acetone to obtain a smooth and clean surface.

[0026] (2) Laser cladding

[0027] The composition and mass fraction of the nickel-based alloy powder used to prepare the coating are: 0.73%C, 4.05%B, 4.66%Si, 0.58%Ce, 0.18%Mg, 19.04%Cr, 0.53%K, 2.47%Fe, Ni Quantity; the particle size range of nickel-based alloy powder is 75-150μm; add pure Nb powder and pure Ta powder with a particle size of 35-45μm to the nickel-based alloy powder, and the addition amount of pure Nb powder and pure Ta powder is nickel-based alloy powder 4.5% and 1.5% of the mass of the composite powder; the mixed powder was mechanically mixed with a planetary ball mill for 3 hours, and aft...

Embodiment 2

[0030] Example 2: The laser power is 1800W, and the amount of pure Nb powder added is 3.0% of the mass of the nickel-based alloy composite powder.

[0031] (1) Cr12MoV steel substrate pretreatment

[0032] The surface of the processed automobile die steel Cr12MoV steel substrate was polished with sandpaper and cleaned with acetone to obtain a smooth and clean surface.

[0033] (2) Laser cladding

[0034]The composition and mass fraction of the nickel-based alloy powder used to prepare the coating are: 0.97%C, 3.24%B, 5.10%Si, 0.37%Ce, 0.27%Mg, 18.26%Cr, 0.69%K, 4.64%Fe, Ni Quantity; the particle size range of nickel-based alloy powder is 75-150μm; add pure Nb powder and pure Ta powder with a particle size of 35-45μm to the nickel-based alloy powder, and the addition amount of pure Nb powder and pure Ta powder is nickel-based alloy powder 3.0% and 2.0% of the mass of the composite powder; the mixed powder was mechanically mixed with a planetary ball mill for 3 hours, and then...

Embodiment 3

[0036] Example 3: The laser power is 1800W, and the amount of pure Nb powder added is 3.8% of the mass of the nickel-based alloy composite powder.

[0037] (1) Cr12MoV steel substrate pretreatment

[0038] The surface of the processed automobile die steel Cr12MoV steel substrate was polished with sandpaper and cleaned with acetone to obtain a smooth and clean surface.

[0039] (2) Laser cladding

[0040] The composition and mass fraction of the nickel-based alloy powder used to prepare the coating are: 0.79%C, 3.50%B, 4.87%Si, 0.43%Ce, 0.23%Mg, 18.71%Cr, 0.62%K, 3.84%Fe, Ni Quantity; the particle size range of nickel-based alloy powder is 75-150μm; add pure Nb powder and pure Ta powder with a particle size of 35-45μm to the nickel-based alloy powder, and the addition amount of pure Nb powder and pure Ta powder is nickel-based alloy powder 3.8% and 1.7% of the mass of the composite powder; the mixed powder was mechanically mixed with a planetary ball mill for 3 hours, and aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com