Heat storage device for dryer

A technology of heat storage device and dryer, applied in drying chamber/container, dry gas arrangement, solar heat storage, etc., can solve the problems of shortened continuous drying time, poor drying effect, short heat storage time, etc., and achieve solar energy utilization rate Improve and improve the effect of heat preservation and high utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

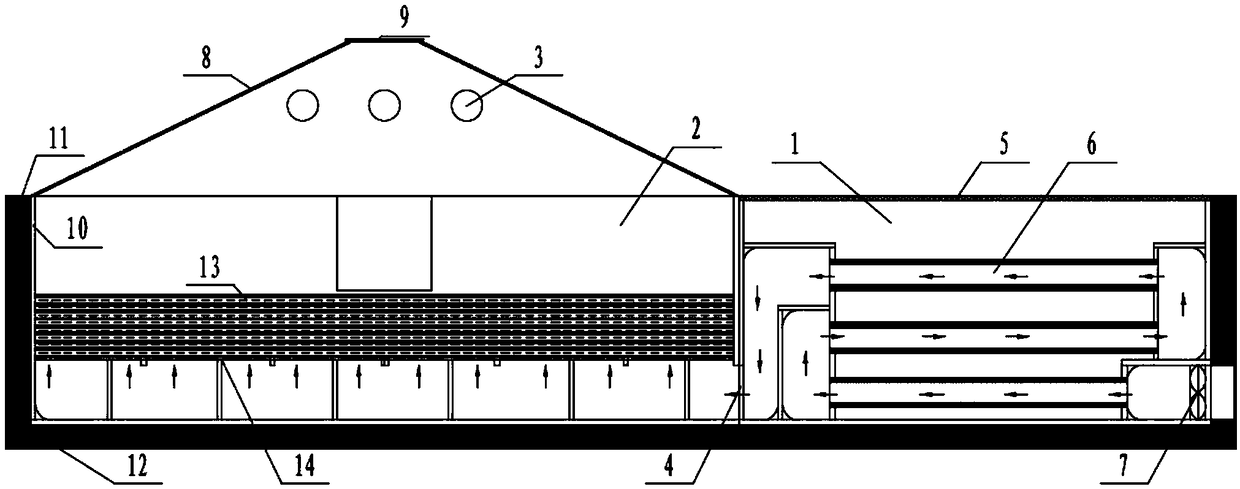

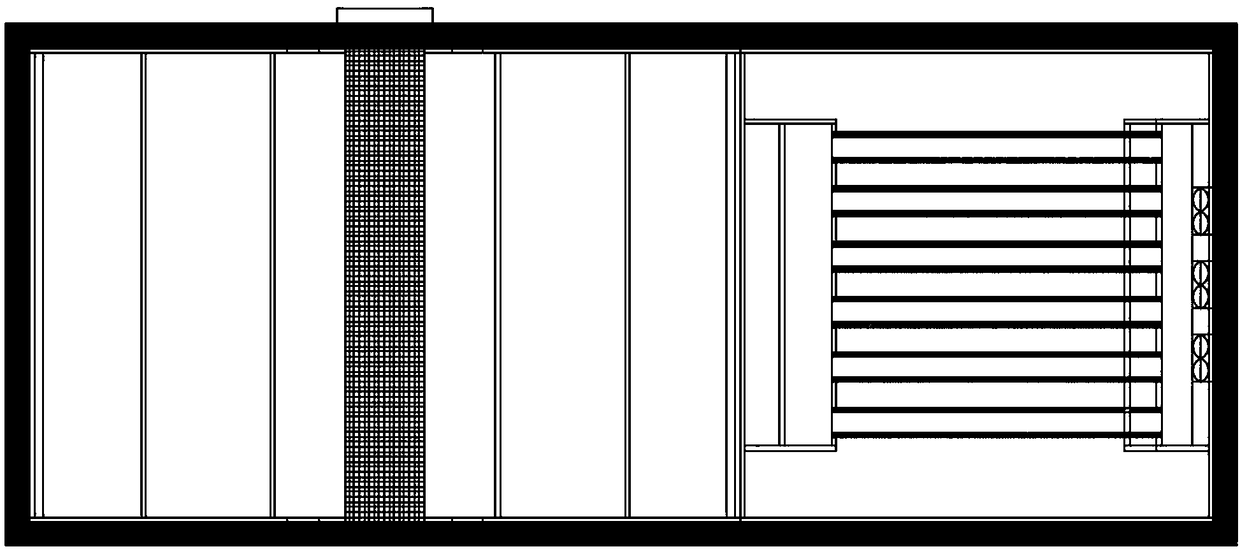

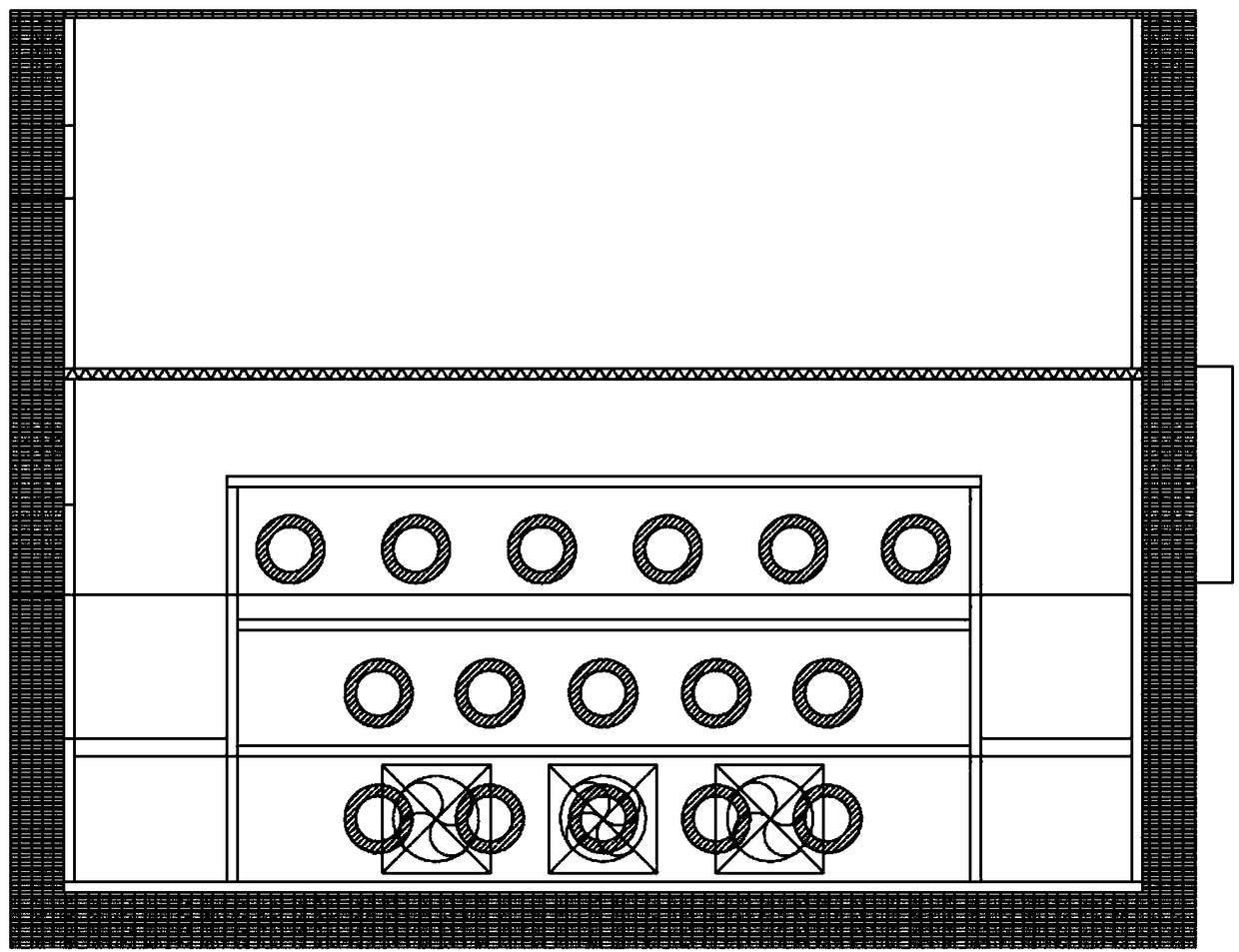

[0032] Example 1: Such as Figure 1-Figure 6 As shown, a heat storage device for a dryer includes an air inlet 4 connected to the heat storage chamber 1 at the bottom of the left side of the heat storage chamber 1, a linear Fresnel lens 5 at the top, and heat storage copper installed inside The tube 6, the heat storage copper tube 6 is connected with a fan 7, and the heat storage copper tube is made of high thermal conductivity copper. The outer wall of the heat storage chamber 1 and the drying chamber 2 is an integral structure, separated by partitions.

[0033] Preferably, the side wall of the heat storage chamber 1 includes an insulation layer 11 and an aluminum alloy layer 12 from the inside to the outside. The insulation layer is made of aluminum silicate, and the aluminum alloy tube layer plays a protective role.

[0034] Preferably, the above-mentioned material placement layer 13 adopts a drawer structure with multiple layers, and is supported by a frame-shaped bracket 14 wh...

Embodiment 2

[0041] Example 2: Such as Figure 1-Figure 6 As shown, the above-mentioned heat storage chamber is used in a dryer. The dryer includes a heat storage chamber 1 and a drying chamber 2 arranged on the left side of the heat storage chamber 1. The drying chamber 2 is provided with an exhaust hole 3 at the top and the bottom right The air inlet 4 is connected to the heat storage chamber 1, a material placement layer 13 is installed inside, a linear Fresnel lens 5 is installed on the top of the heat storage chamber 1, a heat storage copper pipe 6 is installed inside, and a fan 7 is connected to the heat storage copper pipe 6 , The heat storage copper tube is made of high thermal conductivity copper. The outer wall of the heat storage chamber 1 and the drying chamber 2 is an integrated structure, separated by a partition, and the sunlight is focused by a Fresnel lens and then the heat storage copper tube is used for storage The fan blows the hot air flow of the mobile phone in the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com