Industrial gas desulphurization system

A desulfurization system and industrial gas technology, applied in gas treatment, combustion methods, lighting and heating equipment, etc., can solve the problems of high difficulty in automatic control, single types of sulfur-containing compounds, complex chemical reactions in the desulfurization process, etc., to achieve fully automatic Controlling, beneficial to the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

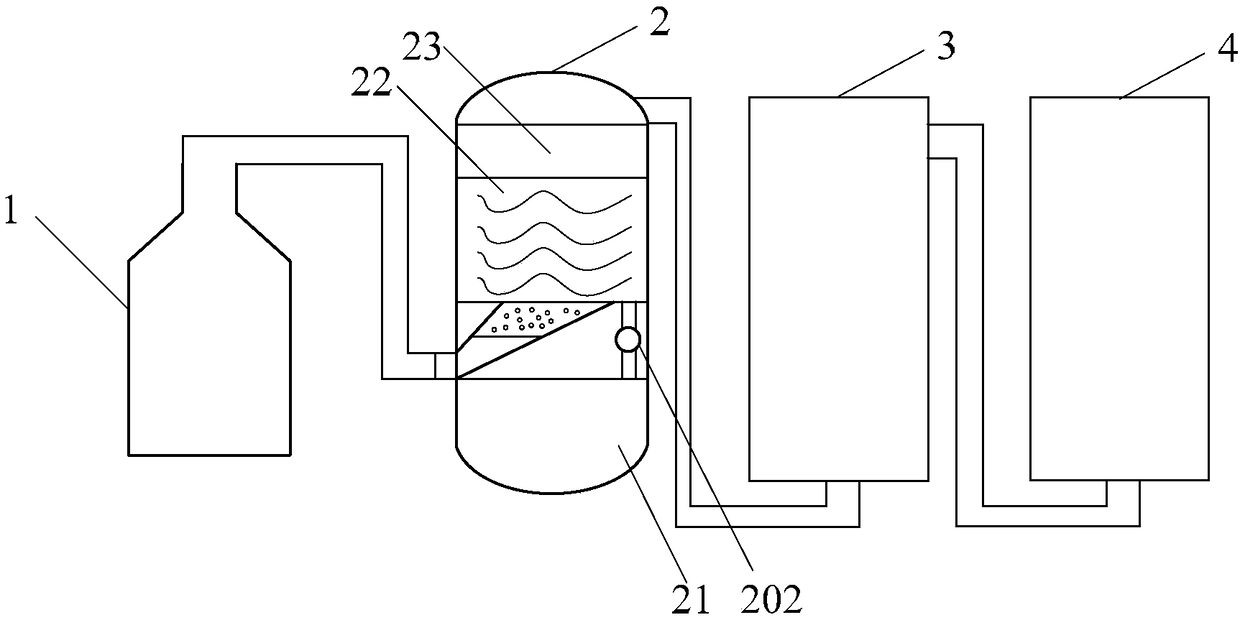

[0024] An industrial gas desulfurization system, such as figure 1 As shown, it includes a gas generating device 1 and a first desulfurization body 2 communicating with the gas generating device 1 . The gas generating device is a device for generating industrial waste gas in the prior art, such as a device for producing industrial waste gas in a chemical plant, a steel plant, a pharmaceutical factory, a coking plant and an oil refinery.

[0025] A slurry pool 21, a spray layer 22, and a demister 23 are sequentially arranged in the first desulfurization body 2 from bottom to top; there is a flue entrance between the slurry pool 21 and the spray layer 22, along the Dust removal components are arranged around the flue gas passage leading to the spray layer 22 at the entrance of the duct to remove particulate matter in the exhaust gas containing sulfide. Limestone slurry is stored in the slurry pool 21. The slurry pool 21 is connected to the spray Layer 22 is connected by a water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com