Gasoline hydrorefining catalyst, and preparation method thereof

A gasoline hydrogenation and catalyst technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of slow coking speed, high metal content, and poor desulfurization and denitrification effects Good and other questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

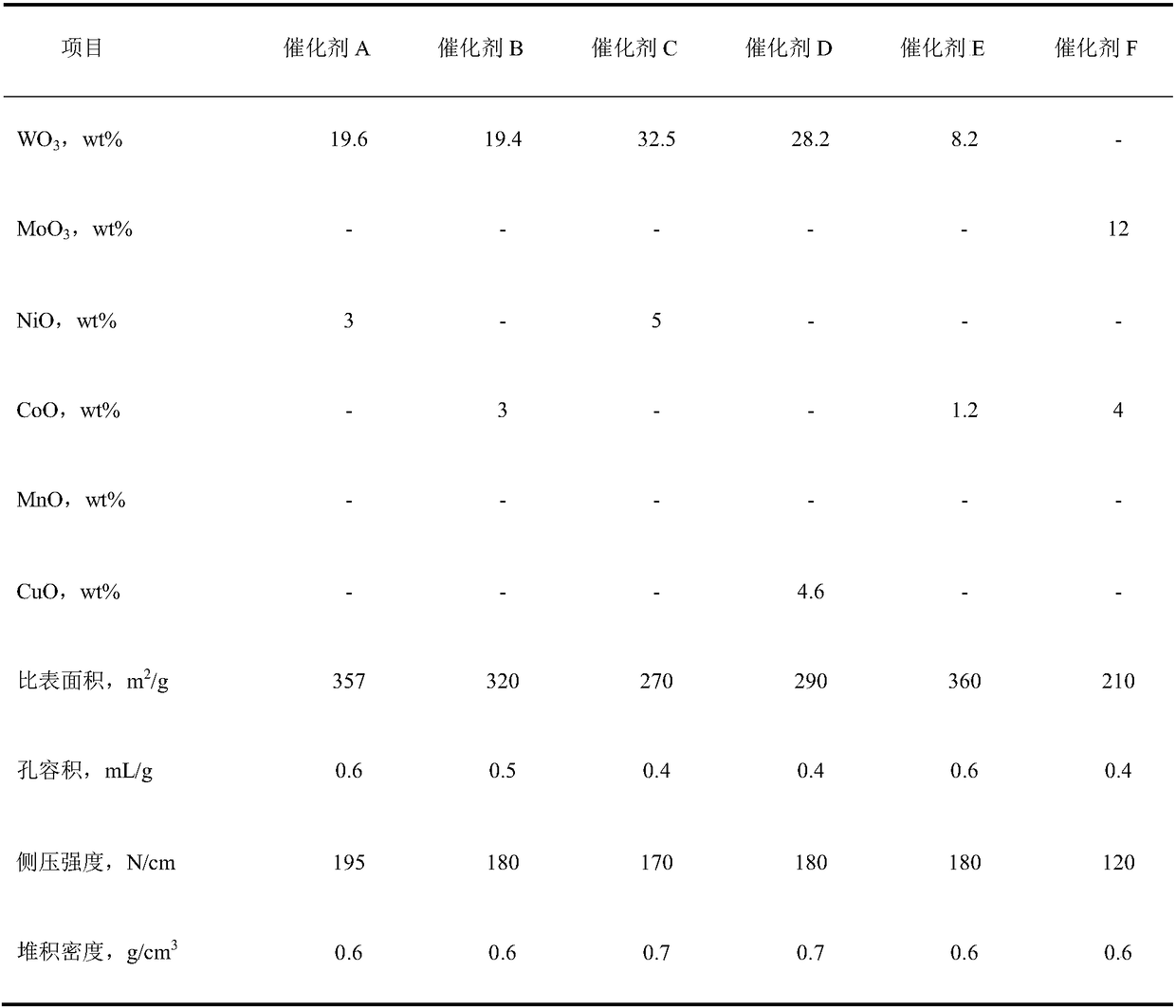

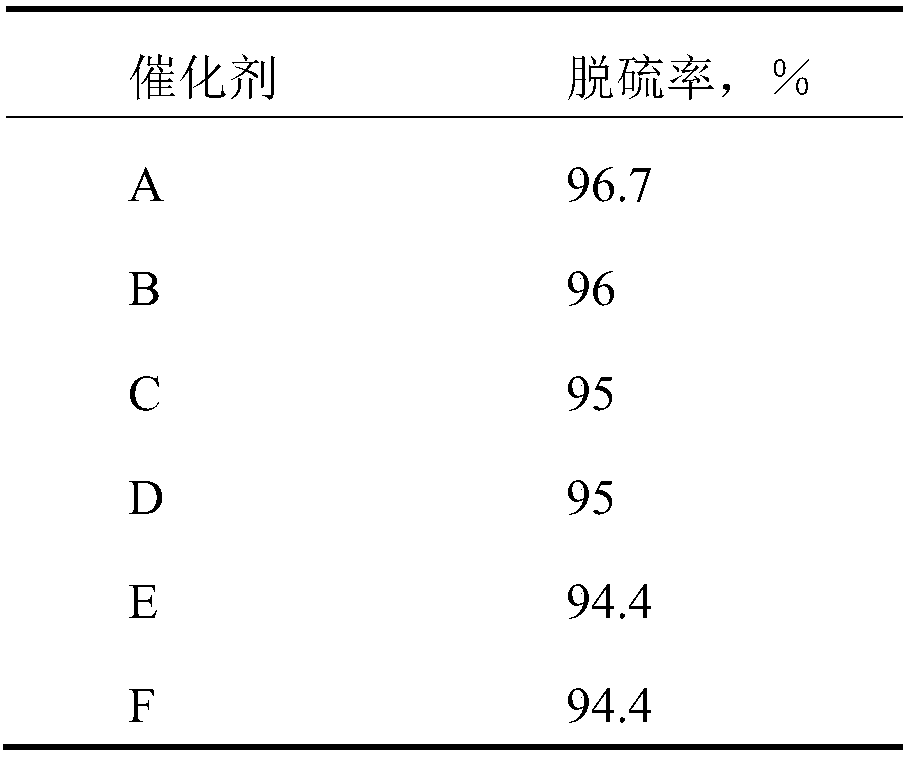

Embodiment 1

[0039] Take 100g of pseudoboehmite, 20g of TS-1 molecular sieve, add 1g of graphene, and mix well. Add 4g of scallop powder, mix evenly, add dropwise a mixed solution consisting of 4g of nitric acid, 4g of citric acid and 40g of deionized water and knead, extrude into a clover shape of 1.5mm, freeze-dry, and then roast at 550°C for 4h to make a carrier . Use Ni again 6 [WNi 3 (H 2 O) 2 (ZnW 9 o 34 ) 2 ] The impregnated solution was impregnated with equal volume, freeze-dried, and calcined at 400°C for 4h to obtain catalyst A.

Embodiment 2

[0041] Take 100g of pseudoboehmite, 20g of TS-1 molecular sieve, add 1g of graphene, and mix well. Add 4g of scallop powder, mix evenly, add dropwise a mixed solution consisting of 4g of nitric acid, 4g of citric acid and 40g of deionized water and knead, extrude into a clover shape of 1.5mm, freeze-dry, and then roast at 550°C for 4h to make a carrier . Reuse Co 6 [WCo 3 (H 2 O) 2 (ZnW 9 o34 ) 2 ] The impregnated solution was impregnated with an equal volume, freeze-dried, and calcined at 400°C for 4h to obtain Catalyst B.

Embodiment 3

[0043] Take 100g of pseudo-boehmite, 84g of TS-1 molecular sieve, add 14g of graphene, and mix well. Add 14g of scallop powder, mix evenly, add dropwise an aqueous solution containing 14g of nitric acid and 14g of citric acid, knead, extrude into 1.5mm cylindrical strips, freeze-dry, and then roast at 550°C for 4h to make a carrier. Use Ni again 6 [WNi 3 (H 2 O) 2 (ZnW 9 o 34 ) 2 ] The impregnated solution was impregnated with equal volume, freeze-dried, and calcined at 400°C for 6h to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com