A kind of core-shell micron silver and its preparation method and application

A micro-silver, core-shell type technology, applied in the direction of botany equipment and methods, applications, metal processing equipment, etc., can solve the problems of large limitations and strong pertinence, and achieve mild conditions, simple operation, and broad-spectrum bactericidal performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

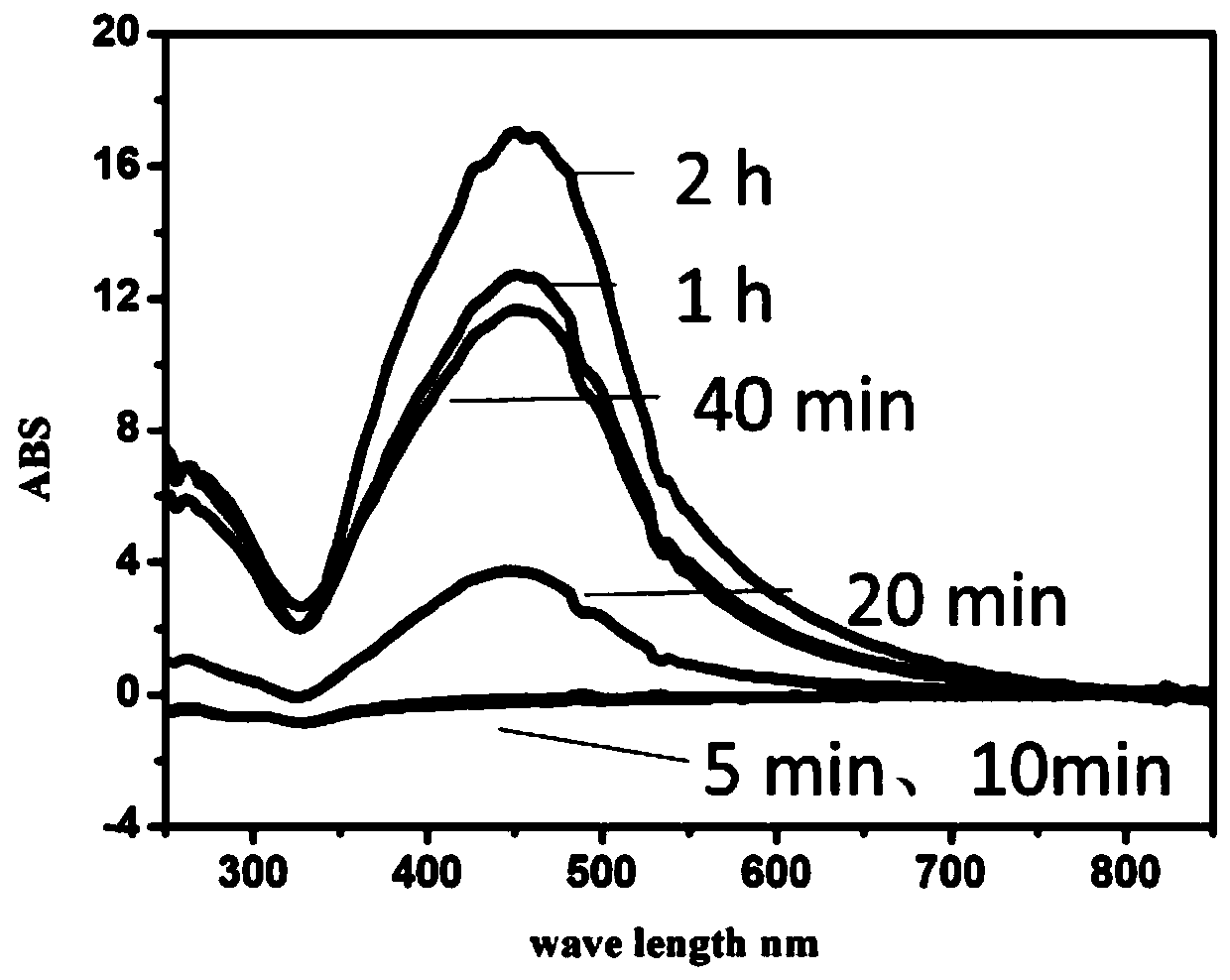

[0026] Dissolve the rhamnolipid in pure water first, make a 1 g / L solution, adjust to pH 6-7, mix well; then add AgNO 3 Add it to the rhamnolipid solution, the final concentration is 1 g / L, and mix well. Place it in a water bath at 80°C for 2 h, and react while stirring. Sampling at 5 min, 10 min, 20 min, 40 min, 1 h, 2 h. The reaction solution was cooled to room temperature, centrifuged, and the precipitate was collected and dissolved in ultrapure water to obtain the product, see figure 2 .

[0027] It can be seen from the figure that with the increase of time, the maximum absorption peak remains unchanged at 451 nm, indicating that with the increase of time, the product is constantly accumulating, and time will not affect the size of nano-silver. After 2 h of reaction, the maximum absorption peak rises to OD 451 =17.06. Therefore, 2 h was selected as the optimal reaction time.

Embodiment 2

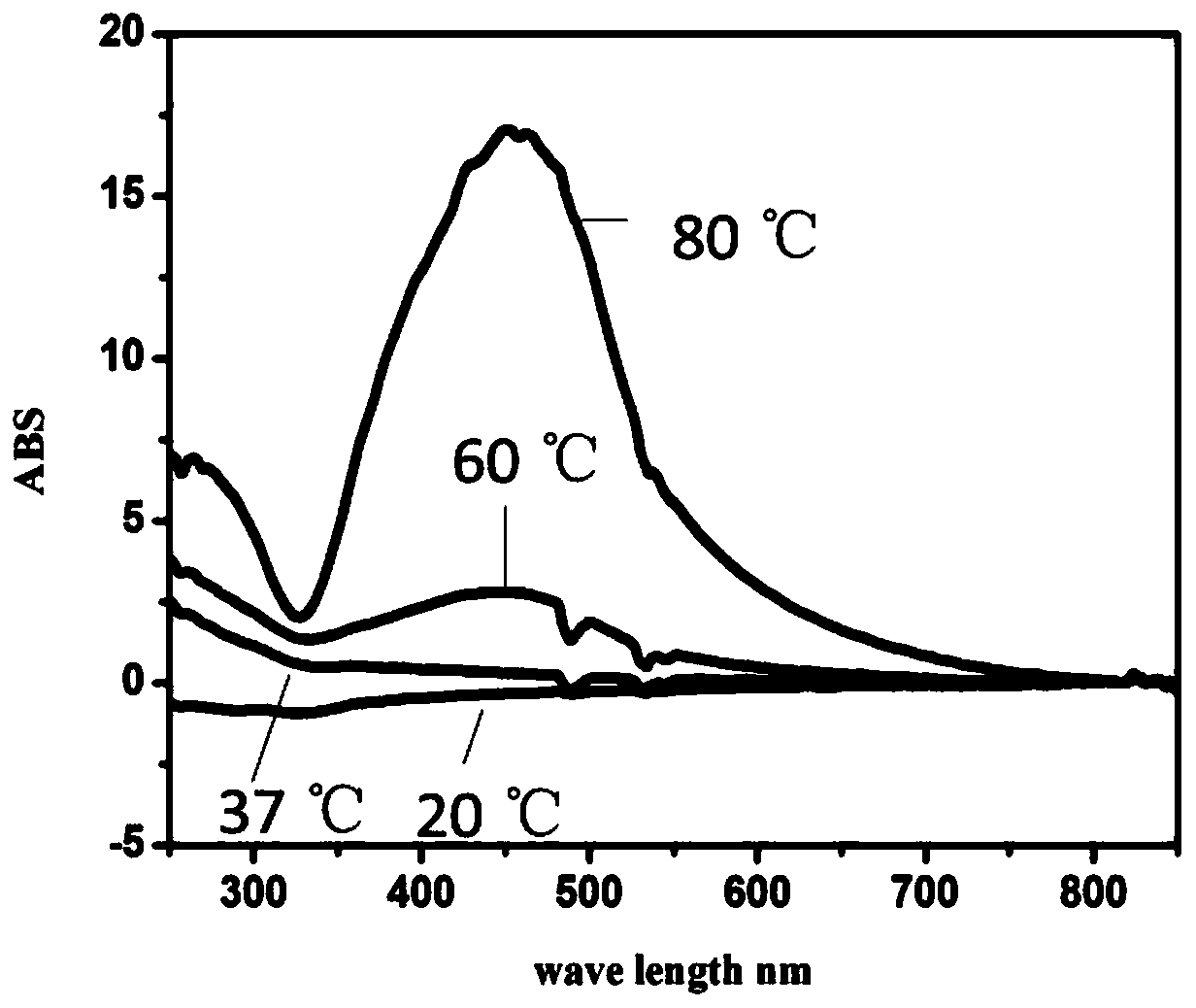

[0029] Dissolve the rhamnolipid in pure water first, make a 1 g / L solution, adjust to pH 6-7, mix well; then add AgNO 3 Add it to the rhamnolipid solution, the final concentration is 1 g / L, and mix well. Place them in water baths at 20°C, 37°C, 60°C, and 80°C for 2 h, and react while stirring. The reaction solution was cooled to room temperature, centrifuged, and the precipitate was collected and dissolved in ultrapure water to obtain the product, see image 3 . It can be seen from the figure that when the reaction temperature is 80°C, the maximum absorption peak of the reactant is the largest. It can be seen that as the temperature increases, the reaction rate is the largest and the yield is the highest. Therefore, the optimal reaction temperature of 80°C was selected.

Embodiment 3

[0031] Dissolve rhamnolipid in pure water first, make 1 g / L, 2 g / L, 4 g / L solutions, adjust to pH 6-7, mix well; then add AgNO 3 Add it to the rhamnolipid solution, the final concentration is 1 g / L, and mix well. Place it in a water bath at 80°C for 2 h, and react while stirring. The reaction solution was cooled to room temperature, centrifuged, and the precipitate was collected and dissolved in ultrapure water to obtain the product, see Figure 4 . It can be seen from the figure that the maximum absorption peaks of the products are different with the addition of different concentrations of rhamnolipids. When the added concentration of rhamnolipid was 1 g / L, the maximum absorption peak of the reactant was the largest. Therefore, the optimal reaction concentration of rhamnolipid was selected as 1 g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com