Preparation method of nitrogen-doped graphitized carbon nanocage

A nano-carbon cage and graphitization technology, which is applied in the direction of nano-carbon, nanotechnology, nanotechnology, etc., can solve the problems of time-consuming and labor-consuming, complicated process of amorphous carbon precursor, and achieve the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The embodiment of the present invention provides a preparation method of nitrogen-doped graphitized nano-carbon cage, the preparation method comprising:

[0030] The cyanamide compound is physically mixed with metal acetate or metal carbonate to obtain a mixture.

[0031] Under the atmosphere of inert gas, the mixture is subjected to carbonization treatment to obtain a carbonized product; the carbonized product is a cyanometallic compound covered with a carbon layer on the surface.

[0032] After the carbonization product is subjected to acid etching to remove the metal compound, an etching product is obtained.

[0033] The etching product is purified to obtain the nitrogen-doped graphitized nano-carbon cage.

[0034] Specifically, the mass ratio of the cyanamide compound to the metal acetate or metal carbonate may be (5-20):1.

[0035] Specifically, the cyanamide compound may be dicyandiamide or melamine.

[0036] Specifically, the metal acetate may be calcium aceta...

Embodiment 1

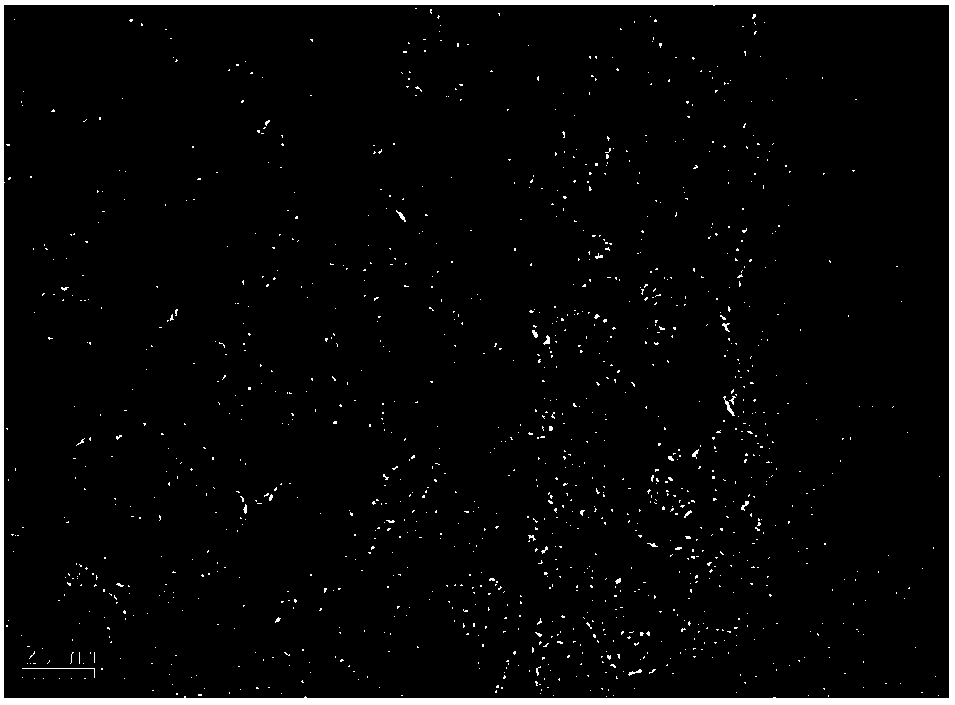

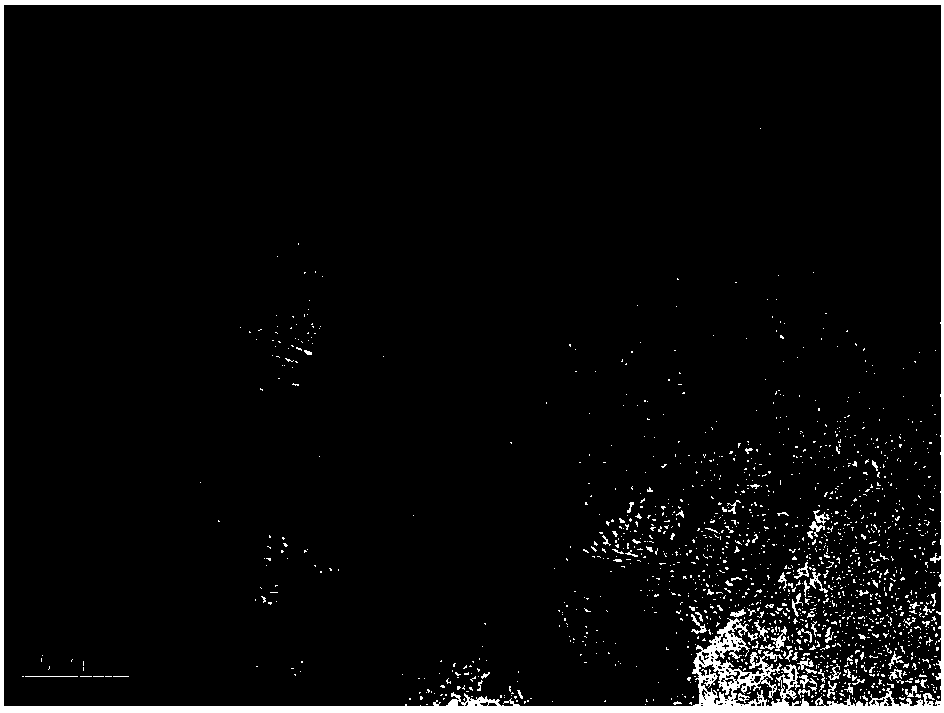

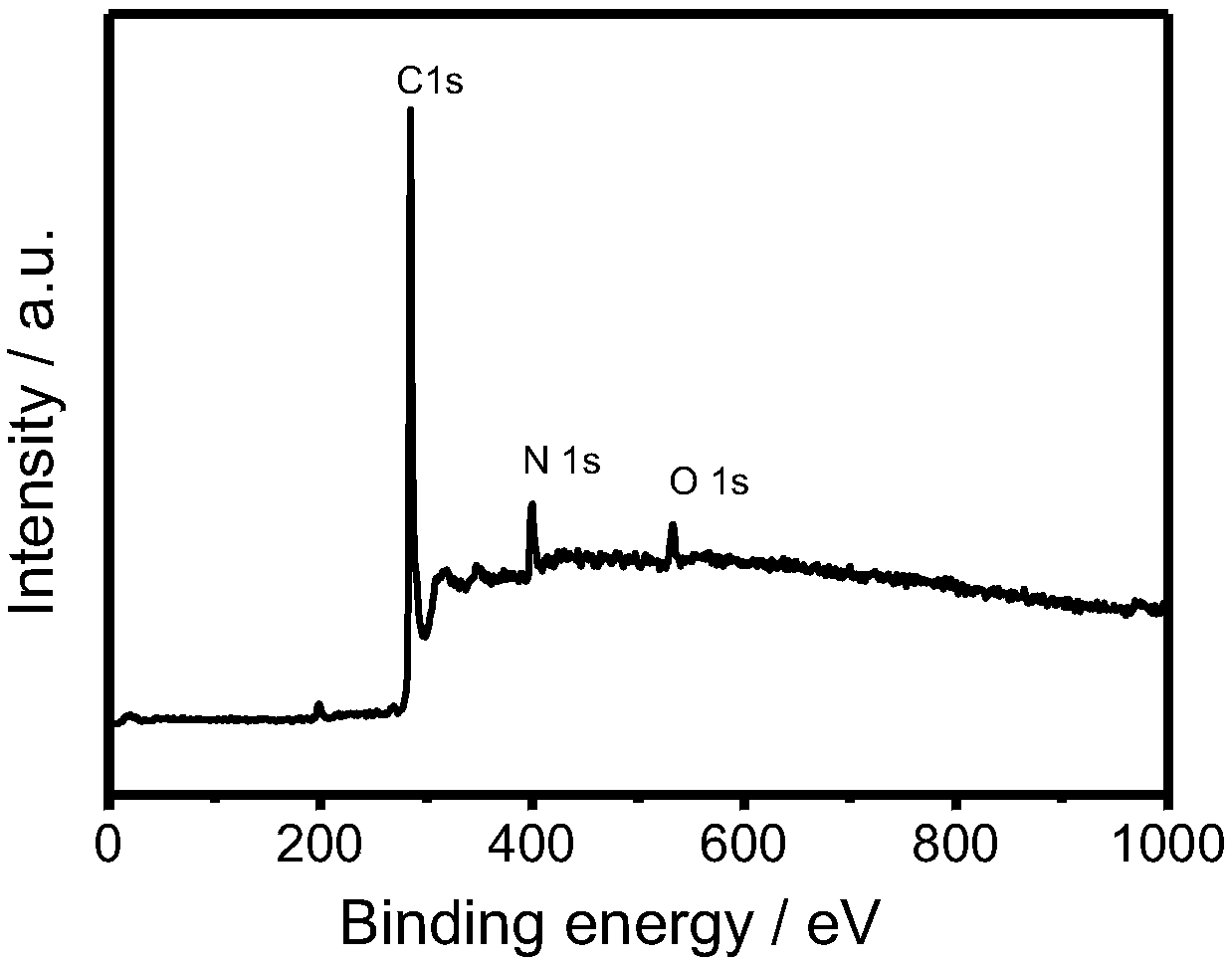

[0044] Physically mix dicyandiamide and calcium acetate with a mass ratio of 5:1 to obtain a mixture. After the mixture is fully ground in a mortar, the mixture is placed on a quartz burning boat, and the quartz burning boat loaded with the mixture is placed on the tube. In a type furnace, under the protection of a nitrogen atmosphere, the temperature was raised from room temperature to 800 °C at a rate of 2 °C / min, kept at 800 °C for 1 h, and then cooled to room temperature to obtain a carbonized product (powder). Put the carbonized product into a round-bottom flask, add a hydrochloric acid solution with a concentration of 3mol / L into the round-bottom flask, and reflux the round-bottom flask at 80°C for 24 hours to obtain an etching product, which is subjected to suction filtration , to obtain a filter cake, repeatedly disperse the filter cake in distilled water and then carry out suction filtration, collect the filtrate respectively until the pH value of the filtrate is 6.8 t...

Embodiment 2

[0048] Physically mix melamine and magnesium acetate with a mass ratio of 10:1 to obtain a mixture. After the mixture is fully ground in a mortar, the mixture is placed on a quartz burning boat, and the quartz burning boat loaded with the mixture is placed in a tube furnace Inside, under the protection of a helium atmosphere, the temperature was raised from room temperature to 800 °C at a rate of 2 °C / min, kept at 800 °C for 3 h, and then cooled to room temperature to obtain a carbonized product (powder). Put the carbonized product into a round bottom flask, add a sulfuric acid solution with a concentration of 5mol / L into the round bottom flask, and reflux the round bottom flask at 80°C for 48 hours to obtain an etching product, which is suction filtered , to obtain a filter cake, repeatedly disperse the filter cake in distilled water and then carry out suction filtration, collect the filtrate respectively until the pH value of the filtrate is 6.8 to 7.2, obtain the washed filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com