Preparation method of multilayered two-dimensional lamellar transition metal carbide material MXene

A transition metal, two-dimensional layered technology, applied in carbides, carbon compounds, chemical instruments and methods, etc., can solve the problems of less applied research, serious environmental pollution, dangerous operation, etc., to improve preparation efficiency and structure stability. Good performance and clear layer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Dissolve 2 g of ammonium fluoride in 30 ml of concentrated hydrochloric acid (concentration: 35 wt %), and stir in a three-necked polytetrafluoroethylene flask for 5 minutes.

[0035] (2) 3gTi 3 AlC 2 Slowly added to the three-necked flask of step (1) within 10 minutes, stirred at a high speed of 300 rpm in a constant temperature oil bath at 50°C for 18h, centrifuged to remove the supernatant, and dried in vacuum at 50°C for 10h.

[0036] (3) the two-dimensional transition metal carbide Ti obtained in step (2) 3 C 2 Add 15ml of dimethyl sulfoxide solvent and stir for 1.5h, centrifuge to remove the supernatant, and vacuum dry at 50°C for 10h.

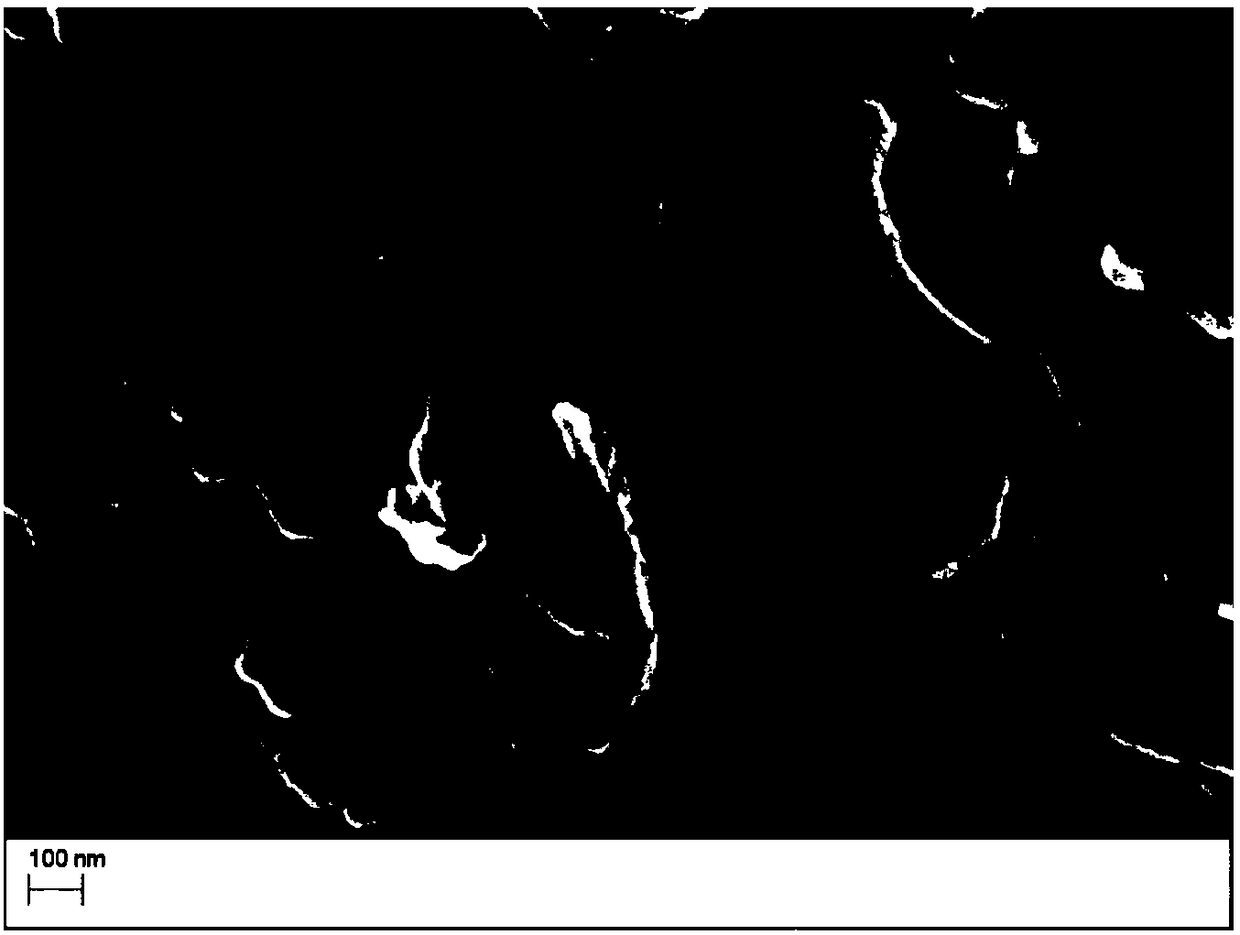

[0037] (4) Ti obtained by step (3) 3 C 2 Mix it with 80ml of deionized water, add it to a multi-functional microreactor, and conduct a hydrothermal reaction at a high temperature of 175°C for 35 minutes, collect the product in the reactor, and obtain a two-dimensional layered transition metal carbide Ti 3 C 2 .

[0038...

Embodiment 2

[0041] (1) Weigh 2g of ammonium fluoride and dissolve it in 30ml of concentrated hydrochloric acid (concentration: 35wt%), and stir in a three-necked polytetrafluoroethylene flask for 10 minutes.

[0042] (2) 3gTi 2 AlC was slowly added to the three-neck flask in step (1) within 10 minutes, stirred at a high speed of 300 rpm in a constant temperature oil bath at 50°C for 18h, centrifuged to remove the supernatant, and dried in vacuum at 50°C for 10h.

[0043] (3) the two-dimensional transition metal carbide Ti obtained in step (2) 2 C was added to 15ml of dimethyl sulfoxide solvent and stirred for 1.5h, centrifuged to remove the supernatant, and dried in vacuum at 50°C for 10h.

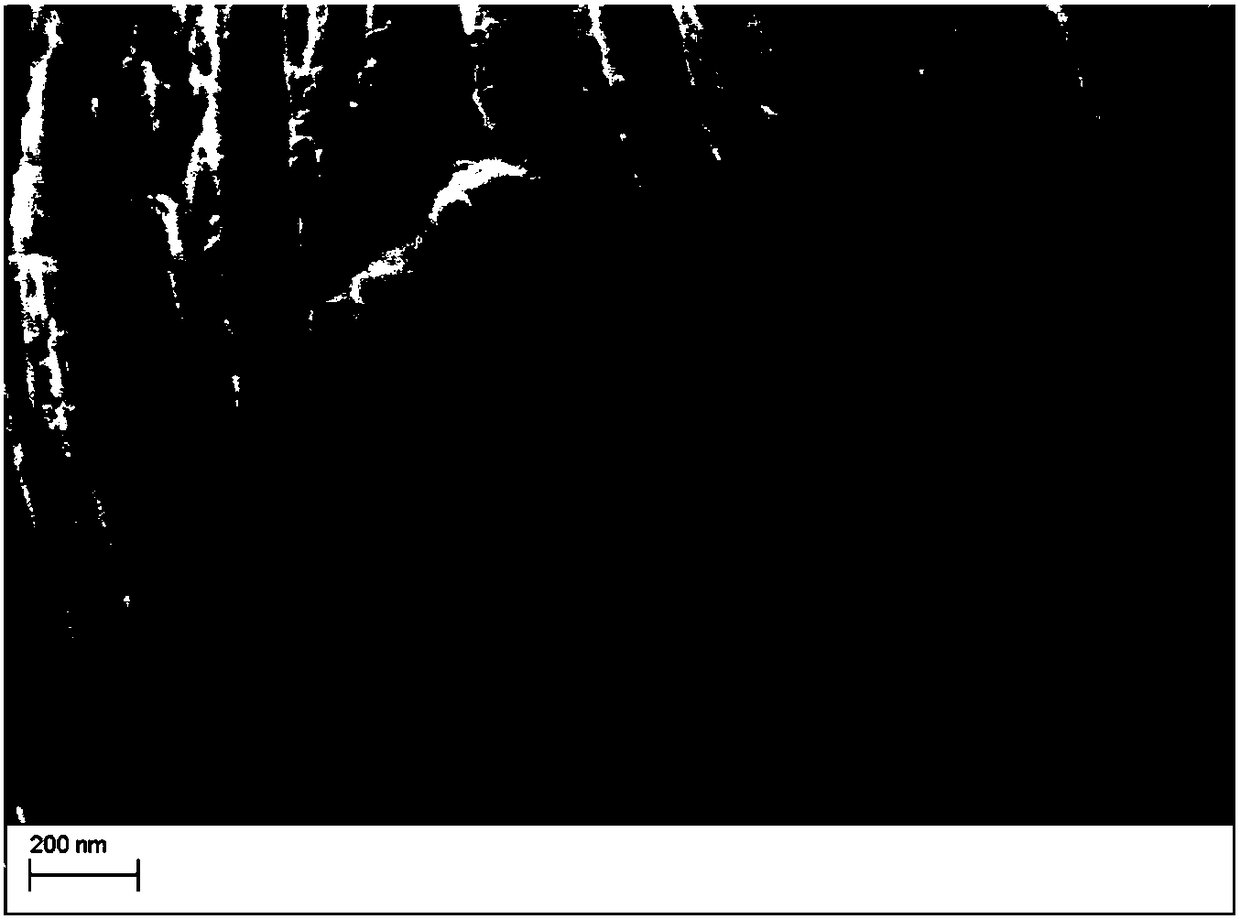

[0044] (4) Ti obtained by step (3) 2 C was mixed with 80ml deionized water, added to a multi-functional micro-reactor and hydrothermally reacted at a high temperature of 175°C for 35 minutes, and the product in the reactor was collected to obtain a two-dimensional layered transition metal carbide Ti...

Embodiment 3

[0048] (1) Weigh 2g of ammonium fluoride and dissolve it in 30ml of concentrated hydrochloric acid (concentration: 35wt%), and stir in a three-necked polytetrafluoroethylene flask for 10 minutes.

[0049] (2) 3gTi 4 SiC 3 Slowly added to the three-necked flask of step (1) within 10 minutes, stirred at a high speed of 300 rpm in a constant temperature oil bath at 50°C for 18h, centrifuged to remove the supernatant, and dried in vacuum at 50°C for 10h.

[0050] (3) the two-dimensional transition metal carbide Ti obtained in step (2) 4 C 3 Add 15ml of dimethyl sulfoxide solvent and stir for 1.5h, centrifuge to remove the supernatant, and vacuum dry at 50°C for 10h.

[0051] (4) Ti obtained by step (3) 4 C 3 Mix it with 80ml of deionized water, add it to a multi-functional microreactor, and conduct a hydrothermal reaction at a high temperature of 175°C for 35 minutes, collect the product in the reactor, and obtain a two-dimensional layered transition metal carbide Ti 4 C 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com