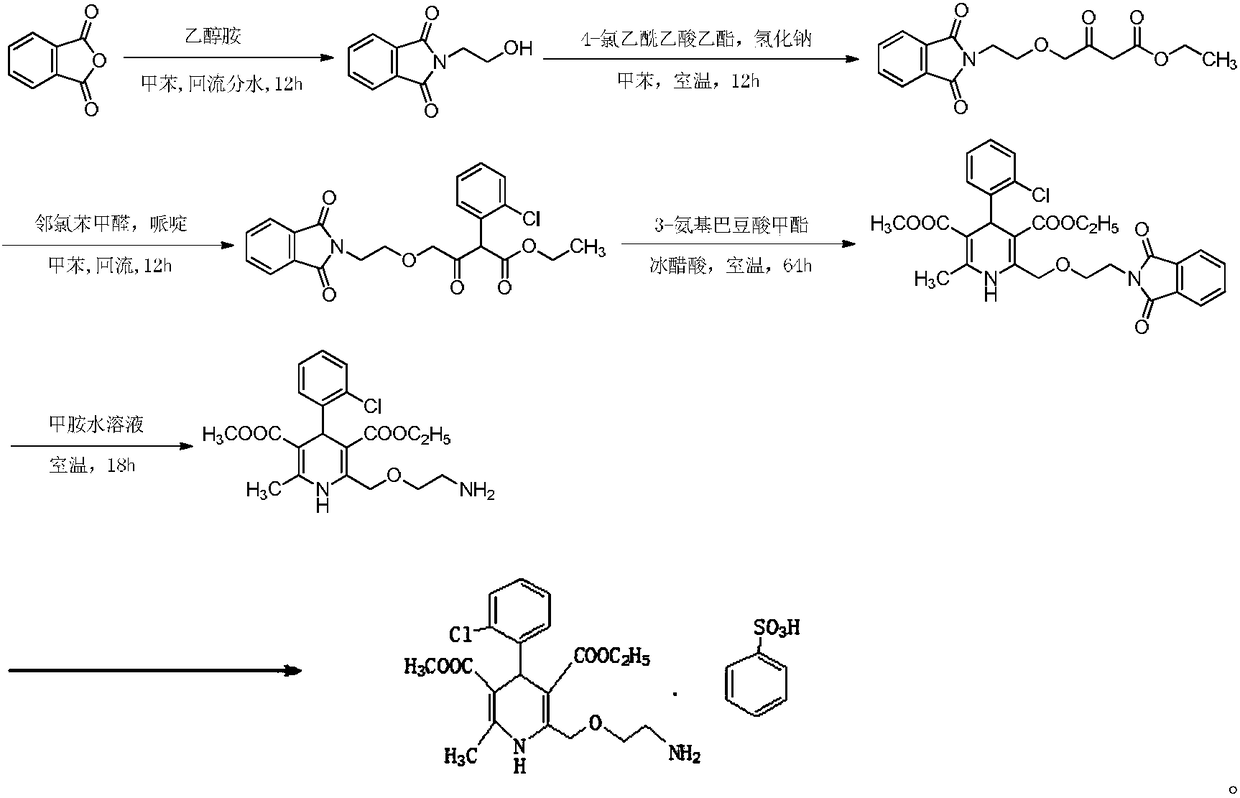

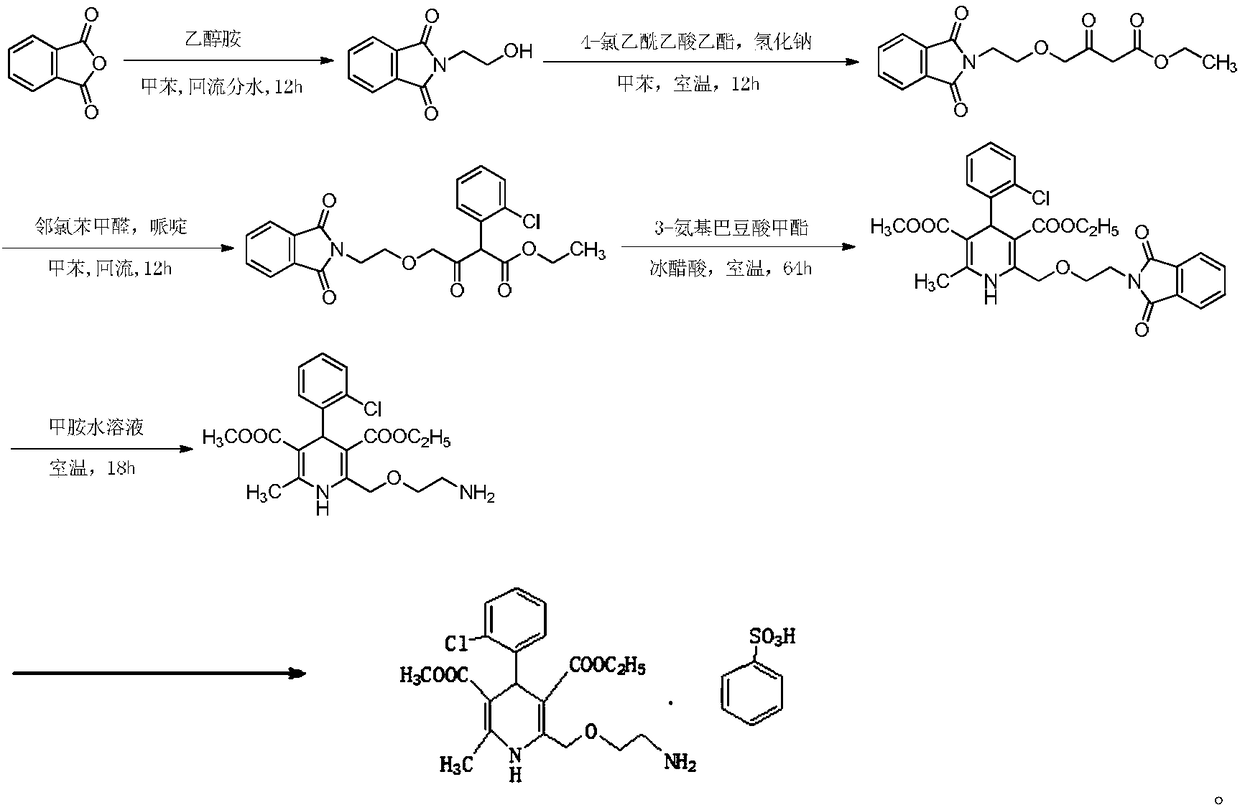

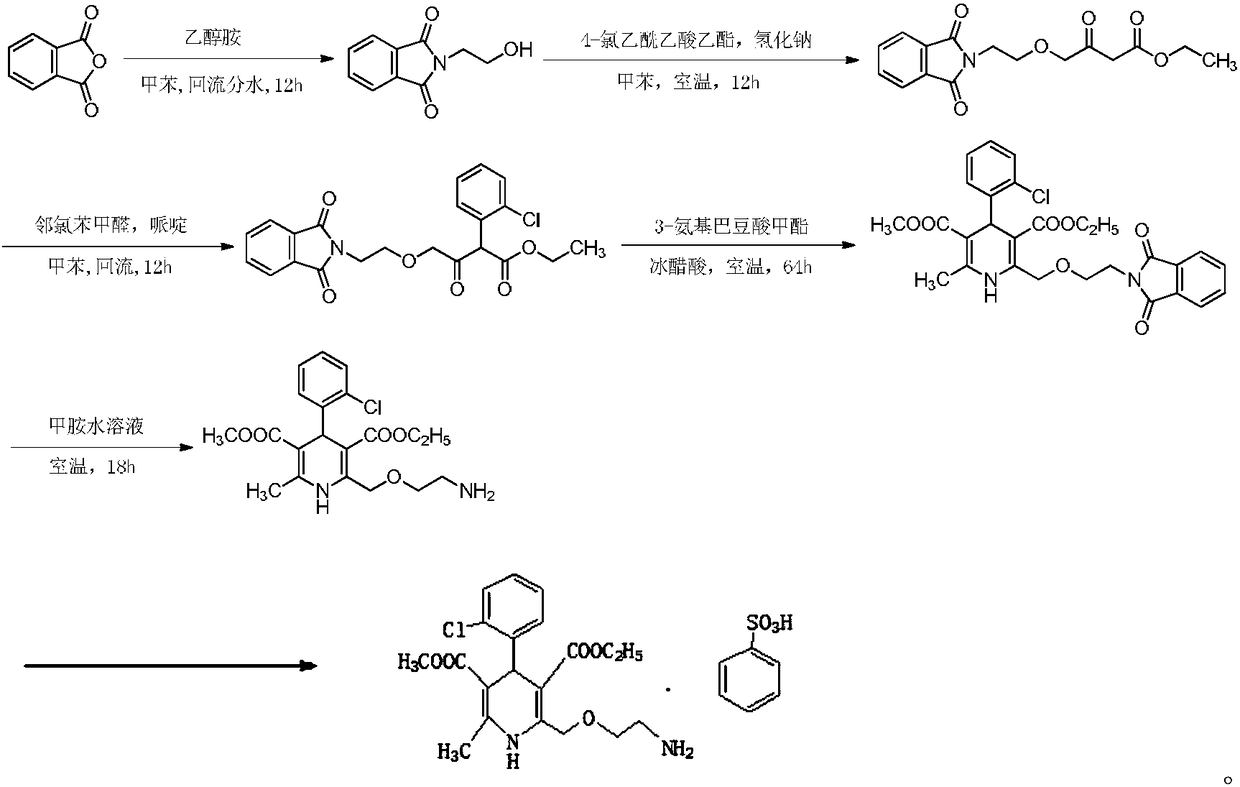

Synthesis process of amlodipine besylate

A kind of technology of amlodipine besylate and synthesis technology, applied in the field of synthesis technology of amlodipine besylate, can solve problems such as unfavorable product quality control, difficult to completely eliminate, increase reaction steps and the like, and achieve product quality controllability The effect of strengthening, reducing synthesis cost and reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: a kind of synthetic technique of amlodipine besylate, comprises the following steps:

[0036] Step 1, the preparation of N-(2-hydroxyethyl)-phthalimide:

[0037]In the reaction tank, put 133kg of toluene, add 40kg of phthalic anhydride under stirring condition, raise the temperature to 60°C, add 16.4kg of ethanolamine dropwise, after adding, raise the temperature to 110°C, reflux and dehydrate for more than 12 hours, cool down to 15°C, and centrifugally filter. Wash the filter residue with toluene, spin dry, dry, dry at 65°C and a vacuum of -0.1MPa, cool down to normal temperature, and discharge to obtain 51kg of N-(2-hydroxyethyl)-phthaloyl Imine, yield 99%, purity 98.5%;

[0038] Step 2, the preparation of 4-[(2-phthalimide) ethoxy] ethyl acetoacetate:

[0039] Put 350kg of toluene into the reaction tank, stir and heat up, and distill the toluene. After the liquid in the water separator is full, keep reflux and water separation for 60 minutes, and take...

Embodiment 2

[0054] Embodiment 2: A kind of synthesis technique of amlodipine besylate, the difference with embodiment 1 is that step 2 specifically includes: in the reaction tank, drop into 350kg toluene, stir and heat up, distill toluene, wait for water separator After the medium liquid is full, keep reflux for 60 minutes to divide the water, and take samples to measure the water division. When the water content of the reflux liquid is ≤0.2%, change the reflux to distillation, distill out toluene, stir and lower the temperature, and when the temperature in the tank drops to 45°C, give Fill the reaction tank with nitrogen, continue to cool down to 5°C, add 40kg of N-(2-hydroxyethyl)-phthalimide under stirring, then add 20kg of sodium hydride, after the addition is complete, cover the tank tightly, Stir under the condition of ℃, pump 38.4kg of ethyl 4-chloroacetoacetate and 45kg of toluene into the metering tank and mix evenly, add the toluene solution of ethyl 4-chloroacetoacetate dropwise...

Embodiment 3

[0055] Embodiment 3: a kind of synthesis technique of amlodipine besylate, the difference with embodiment 1 is that step 4 specifically includes: in the reaction tank, drop into 2-(2-chloro-benyl)-4-[ The toluene solution of (2-phthalimide)ethoxy]ethyl acetoacetate was distilled under reduced pressure below 65°C, the toluene was recovered, 56kg of n-hexane was added, stirred for 25 minutes, cooled to 25°C, and allowed to stand After 15 minutes, take out the n-hexane lotion, then add 56kg of n-hexane, stir at 25°C, let stand, then draw out the n-hexane lotion, distill the remaining n-hexane under reduced pressure at 25°C, add 240kg of glacial acetic acid , stir to dissolve the material, add 64kg methyl 3-aminocrotonate, maintain the internal temperature at 25°C, stir and react for more than 65 hours, centrifugally filter, wash the filter residue with 50kg glacial acetic acid, spin dry, and dry at 60°C until it loses weight on drying ≤5%, cooled to normal temperature, and discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com