A negative electrode for an all-vanadium redox flow battery, its preparation method, and an all-vanadium redox flow battery

An all-vanadium redox flow battery and negative electrode technology, which is applied in battery electrodes, regenerative fuel cells, circuits, etc., can solve the problems of poor electrochemical activity and kinetic reversibility, etc., to weaken the hydrogen evolution side reaction, increase the binding rate, and broad The effect of market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

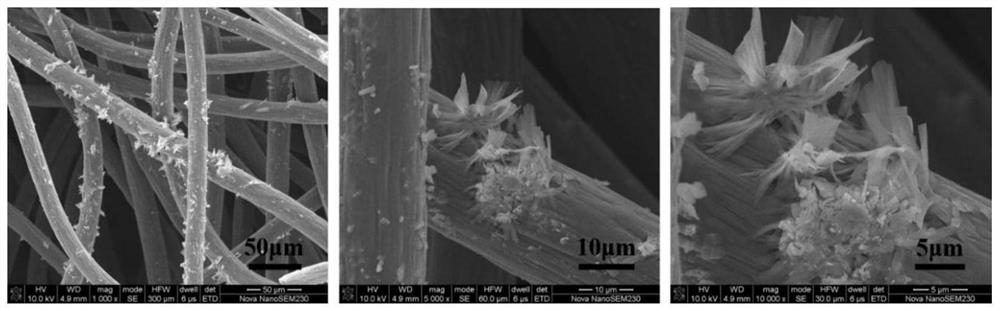

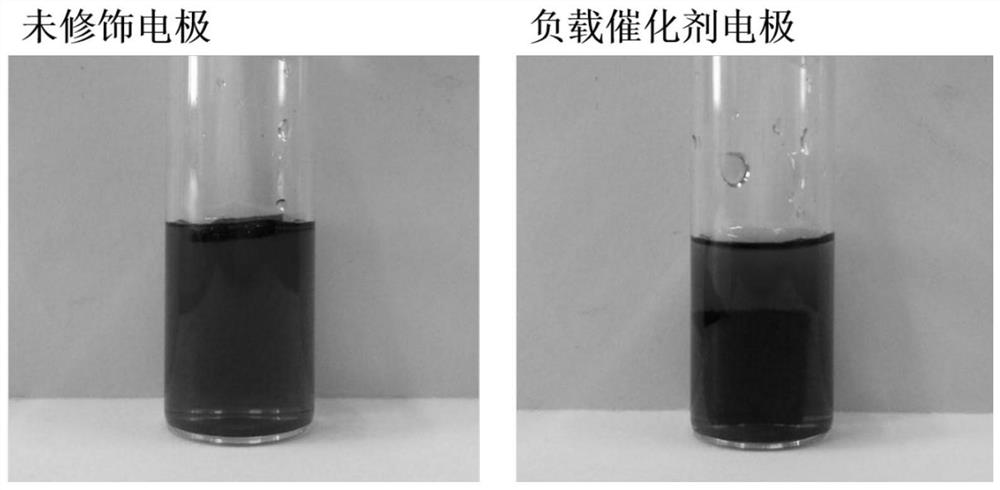

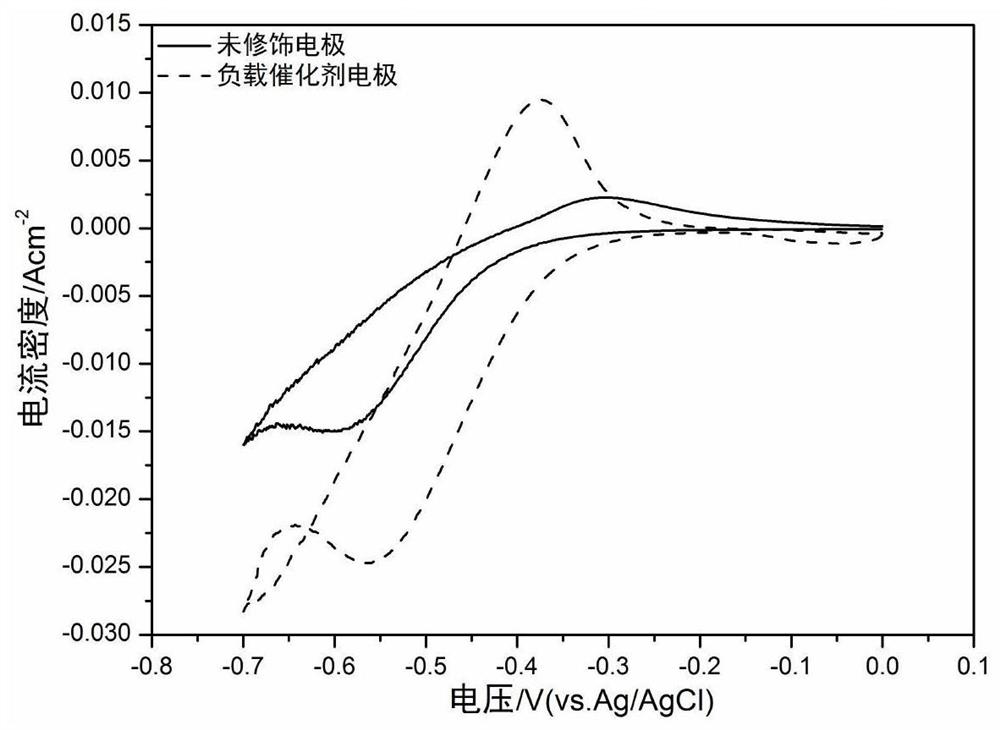

[0043] A negative electrode for an all-vanadium redox flow battery, comprising a carbon electrode substrate and a catalyst loaded on the surface of the carbon electrode substrate, wherein the carbon electrode substrate is carbon felt, and its length, width and thickness are respectively cut to 15 mm, 10 mm and 10 mm. 1.5mm, the catalyst is bismuth-ethylenediaminetetraacetic acid complex.

[0044] The preparation method of the negative electrode for the all-vanadium redox flow battery of the present embodiment comprises the following steps:

[0045] (1) Activated carbon electrode substrate: Soak the carbon felt in 18mol / L sulfuric acid, heat it at 80°C for 5h, wash it with deionized water several times until the pH is 7.0, then dry it at 60°C for 12h, and finally transfer Put it in a vacuum drying oven, and then dry it at 80°C for 16 hours to obtain an activated carbon felt electrode, which is stored for future use;

[0046] (2) Dissolving the bismuth-ethylenediaminetetraaceti...

Embodiment 2

[0049] A negative electrode for an all-vanadium redox flow battery, comprising a carbon electrode substrate and a catalyst loaded on the surface of the carbon electrode substrate, wherein the carbon electrode substrate is carbon cloth, and its length, width and thickness are respectively cut to 16mm, 11mm and 0.3mm, the catalyst is bismuth-ethylenediaminetetraacetic acid complex.

[0050] The preparation method of the negative electrode for the all-vanadium redox flow battery of the present embodiment comprises the following steps:

[0051] (1) Activated carbon electrode substrate: Soak the carbon cloth in 16mol / L sulfuric acid, heat it at 70°C for 6h, wash it with deionized water several times until the pH is 7.0, then dry it at 60°C for 6h, and finally transfer Put it in a vacuum drying oven, and then dry it at 60°C for 12 hours to obtain an activated carbon cloth electrode, which is stored for future use;

[0052] (2) Dissolving the bismuth-EDTA complex in N,N-dimethylform...

Embodiment 3

[0057] A negative electrode for an all-vanadium redox flow battery, comprising a carbon electrode substrate and a catalyst loaded on the surface of the carbon electrode substrate, wherein the carbon electrode substrate is carbon felt, and its length, width and thickness are respectively cut to 60 mm, 50 mm and 6mm, the catalyst is bismuth-ethylenediaminetetraacetic acid complex.

[0058] The preparation method of the negative electrode for the all-vanadium redox flow battery of the present embodiment comprises the following steps:

[0059] (1) Activated carbon electrode substrate: Soak carbon felt in 18mol / L sulfuric acid, heat at 90°C for 4h, wash with deionized water several times to pH 6.5, then dry at 60°C for 24h, and finally transfer Put it in a vacuum drying oven, and then dry it at 80°C for 24 hours to obtain an activated carbon felt electrode, which is stored for future use;

[0060] (2) Dissolving the bismuth-ethylenediaminetetraacetic acid complex in N,N-dimethylfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com