High-power microwave hole interior fracturing device for engineering rock mass

一种大功率、微波的技术,应用在隔离装置、微波加热、微波激射器等方向,能够解决安装和拆卸不方便、微波发生器体积庞大、微波能利用效率降低等问题,达到方便现场安装和拆卸、避免击穿打火现象、降低微波反射功率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

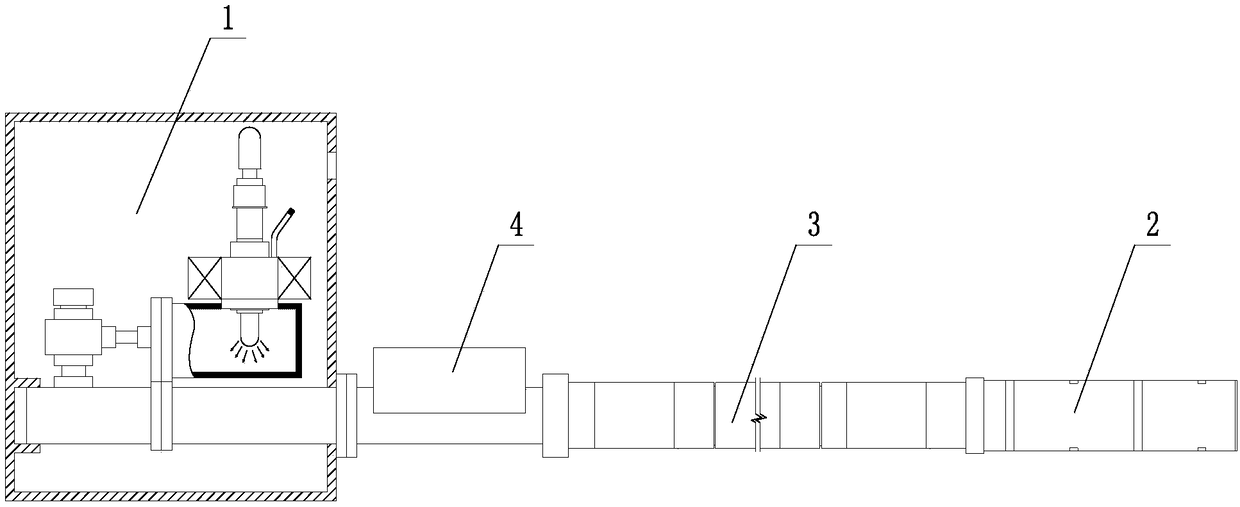

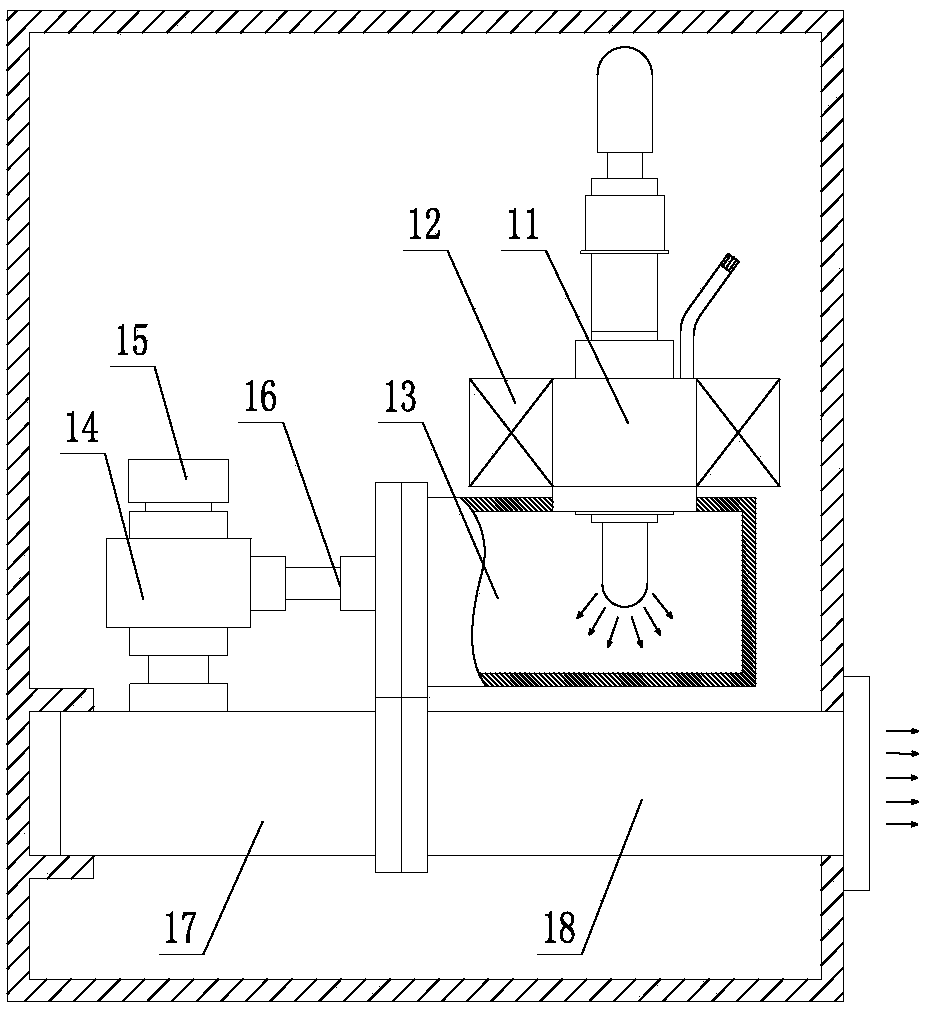

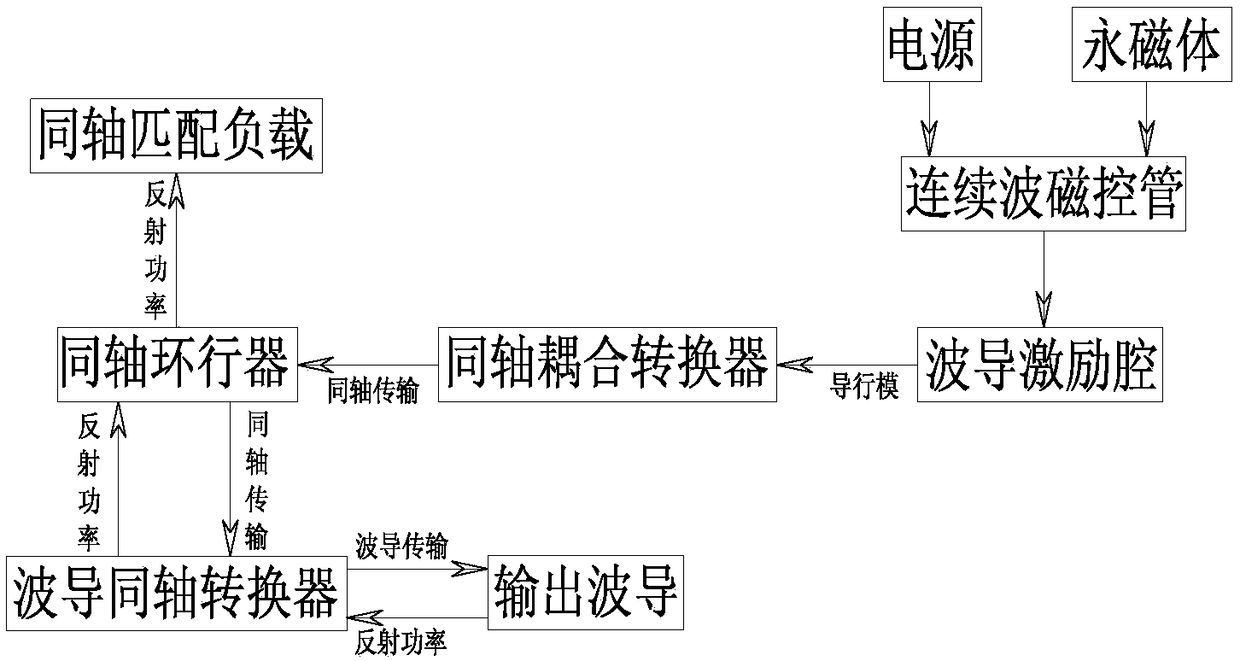

[0035] Such as Figure 1-12 As shown, a high-power microwave in-hole fracturing device for engineering rock mass includes a high-power microwave generator 1, a high-power microwave coaxial heater 2, a high-power low-loss microwave coaxial transmission line 3 and a microwave power adaptive control system 4; the high-power microwave generator 1 is sequentially connected to the high-power microwave coaxial heater 2 through the microwave power adaptive control system 4 and the high-power low-loss microwave coaxial transmission line 3; the high-power microwave coaxial heater 2 It is used to radiate microwave energy to cause cracking of rocks around engineering rock mass holes; the microwave power adaptive control system 4 is used to match the microwave power output by the high-power microwave generator 1 in real time; the high-power low-lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com