Reforming reactor used in vapor reforming hydrogen production device

A technology of steam reforming and reforming reactor, which is applied in the directions of hydrogen, steam generation, climate sustainability, etc., can solve the problem that the waste heat of high temperature flue gas is not fully utilized, the structure of the reforming reactor is complicated, and the cost of hydrogen production is high. and other problems, to achieve the effect of reducing equipment space, improving speed and conversion rate, and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

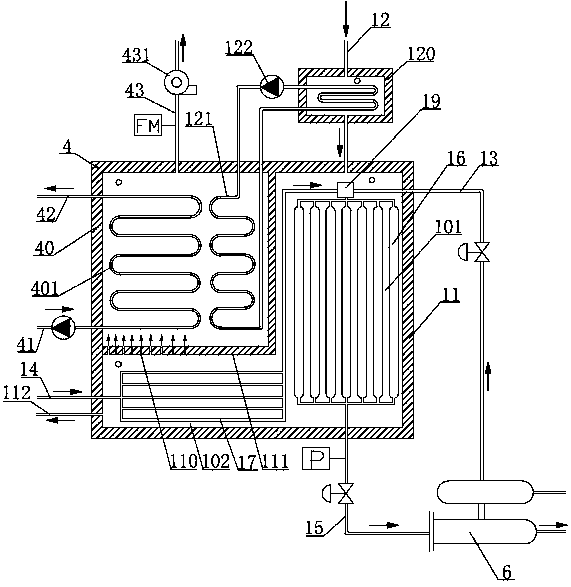

[0019] Such as figure 1 As shown, the reforming reactor in the steam reforming hydrogen production device includes: a shell 11, and the shell 11 is provided with a flue gas input pipe 12, a water vapor input pipe 13, a material delivery pipe 14, and a reformed gas output pipe. Tube 15. The housing 11 is divided into a reforming zone 101 and a heat storage zone 102 . Several reaction tubes 16 are arranged in the reforming zone 101, the flue gas input pipe 12 communicates with the shell 11 at the feed end of the reaction tube 16, and the reformed gas output tube 15 communicates with the discharge end of the reaction tube 16 and extends out of the shell. Body 11. The heat storage area 102 is located on the side of the discharge end of the reaction tube 16. A number of material preheating pipes 17 are arranged in the heat storage area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com