Preparation method of phellinus linteus polysaccharides

A technology of Phellinus linteus and polysaccharide, applied in the field of extraction of natural products, can solve the problems of fluctuation of polysaccharide extraction yield, unstable dissolved quality, strict reaction conditions, etc., and achieve the effects of improving medicinal value, easy operation and improving purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

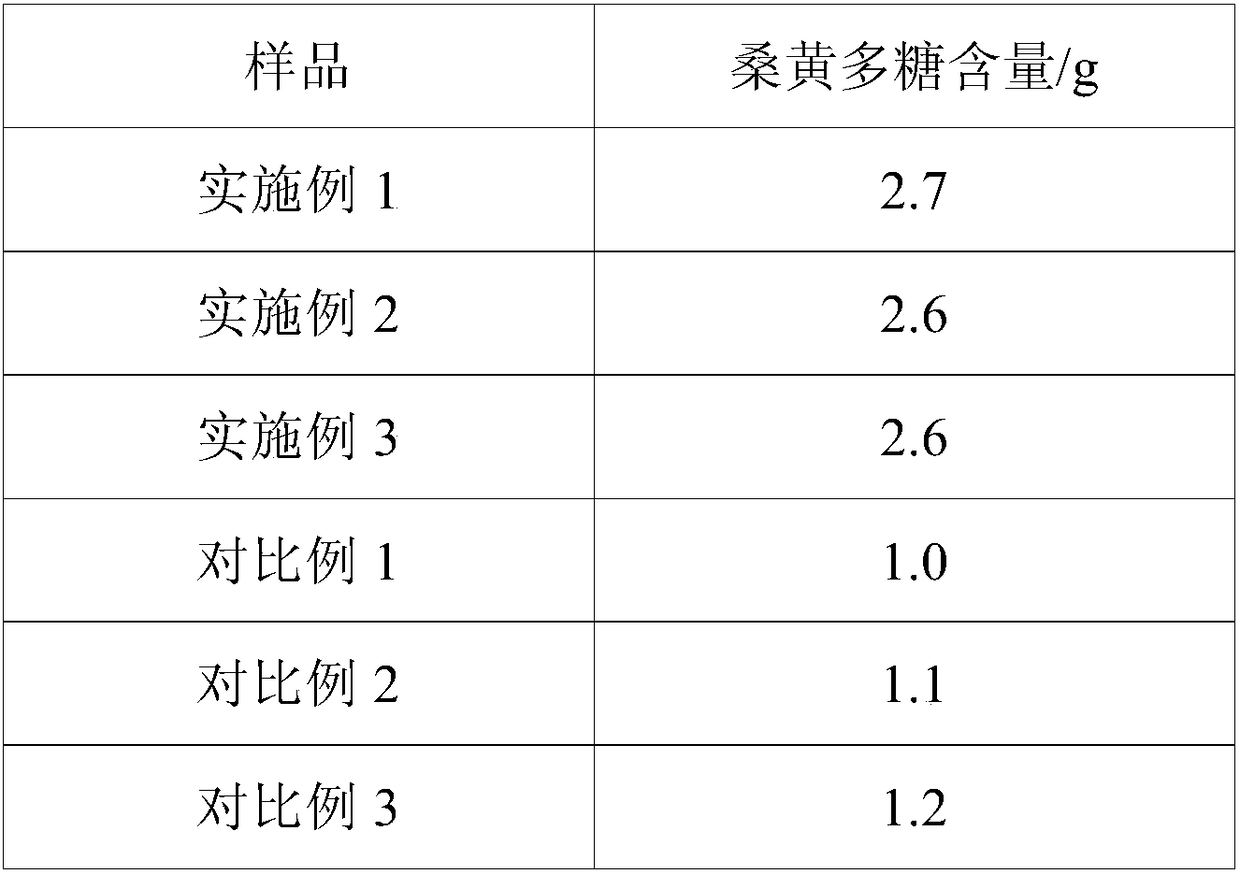

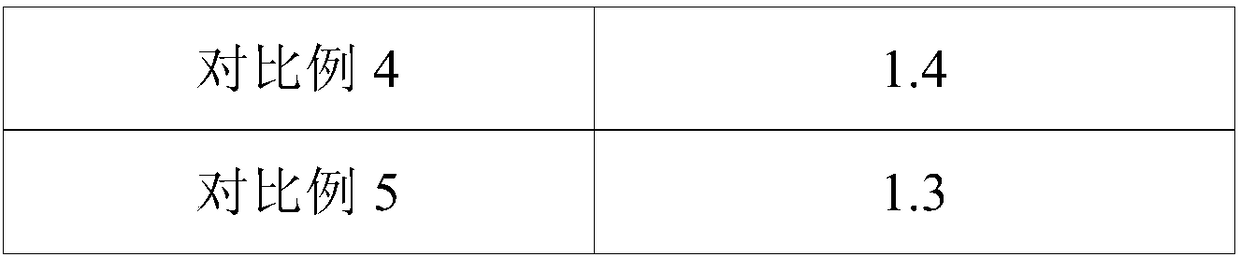

Examples

Embodiment 1

[0024] A preparation method of Phellinus polysaccharide, comprising the following steps:

[0025] (1) Get 1 kg of wild Phellinus japonica to remove impurities and pulverize it to a particle size of 80 orders with a universal pulverizer;

[0026] (2) freezing the Phellinus Phellinus crushed in the above step (1) at -25°C to obtain a freeze-dried powder;

[0027] (3) The freeze-dried powder obtained in step (2) is mechanically broken at -15°C, and the particle diameter after breaking is 20 μm;

[0028] (4) Adding water to the Phellinus Phellinus powder treated by the above step (3) for leaching, the mass ratio of Phellinus Phellinus powder and water is 1:30, the extraction process is leaching at 50°C for 40min, and leaching at 70°C for 90min , leached at 90°C for 70 minutes, filtered and then took the filtrate, concentrated under reduced pressure to obtain the water extract;

[0029] (5) Add 3 times the volume of ethanol, n-butanol and methanol to the water extract in the abov...

Embodiment 2

[0032] A preparation method of Phellinus polysaccharide, comprising the following steps:

[0033] (1) Get 1 kg of wild Phellinus japonica to remove impurities and pulverize it to a particle size of 90 orders with a universal pulverizer;

[0034] (2) freezing the Phellinus Phellinus crushed in the above step (1) at -20°C to obtain a freeze-dried powder;

[0035] (3) The freeze-dried powder obtained in step (2) is mechanically broken at -12°C, and the particle diameter after breaking is 25 μm;

[0036] (4) Add water to the phellinus powder treated in the above step (3) for leaching, the mass ratio of phellinus powder and water is 1:35, the extraction process is leaching at 55°C for 35min, and leaching at 75°C for 80min , leached at 95°C for 65 minutes, filtered and then took the filtrate, concentrated under reduced pressure to obtain the water extract;

[0037] (5) Add 4 times the volume of ethanol, n-butanol and methanol mixture to the water extract in the above step (4) for ...

Embodiment 3

[0040] A preparation method of Phellinus polysaccharide, comprising the following steps:

[0041] (1) Get 1kg of wild Phellinus japonica to remove impurities and pulverize it to a particle size of 100 orders with a universal pulverizer;

[0042] (2) freezing the Phellinus Phellinus pulverized in the above step (1) at -18°C to obtain a freeze-dried powder;

[0043] (3) The freeze-dried powder obtained in step (2) is mechanically broken at -10°C, and the particle diameter after breaking is 30 μm;

[0044] (4) Add water to the phellinus powder treated by the above step (3) for leaching, the mass ratio of phellinus powder and water is 1:40, the extraction process is leaching at 60°C for 30min, and leaching at 80°C for 70min , leached at 100°C for 60 minutes, filtered and then took the filtrate, concentrated under reduced pressure to obtain the water extract;

[0045] (5) Add 5 times the volume of ethanol, n-butanol and methanol to the water extract in the above step (4) to preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com