Method for preparing superparamagnetic microspheres with surfactant-based nuclear shell

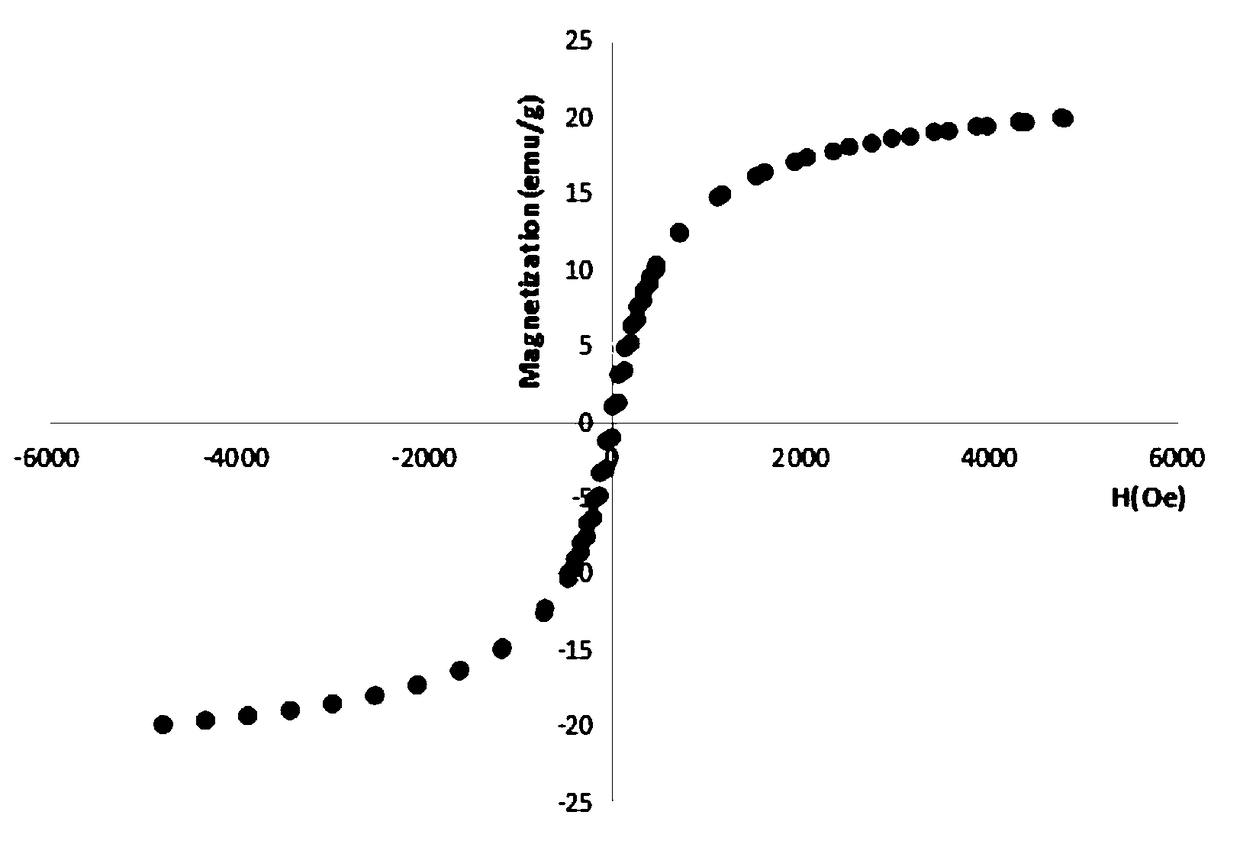

A superparamagnetic and microsphere technology, which is applied in the preparation of surface carboxyl core-shell superparamagnetic polymer microspheres, can solve the problems of less surface functional groups, low magnetic content, leaching of magnetic particles, etc., and achieve monodispersity Good, controllable magnetic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

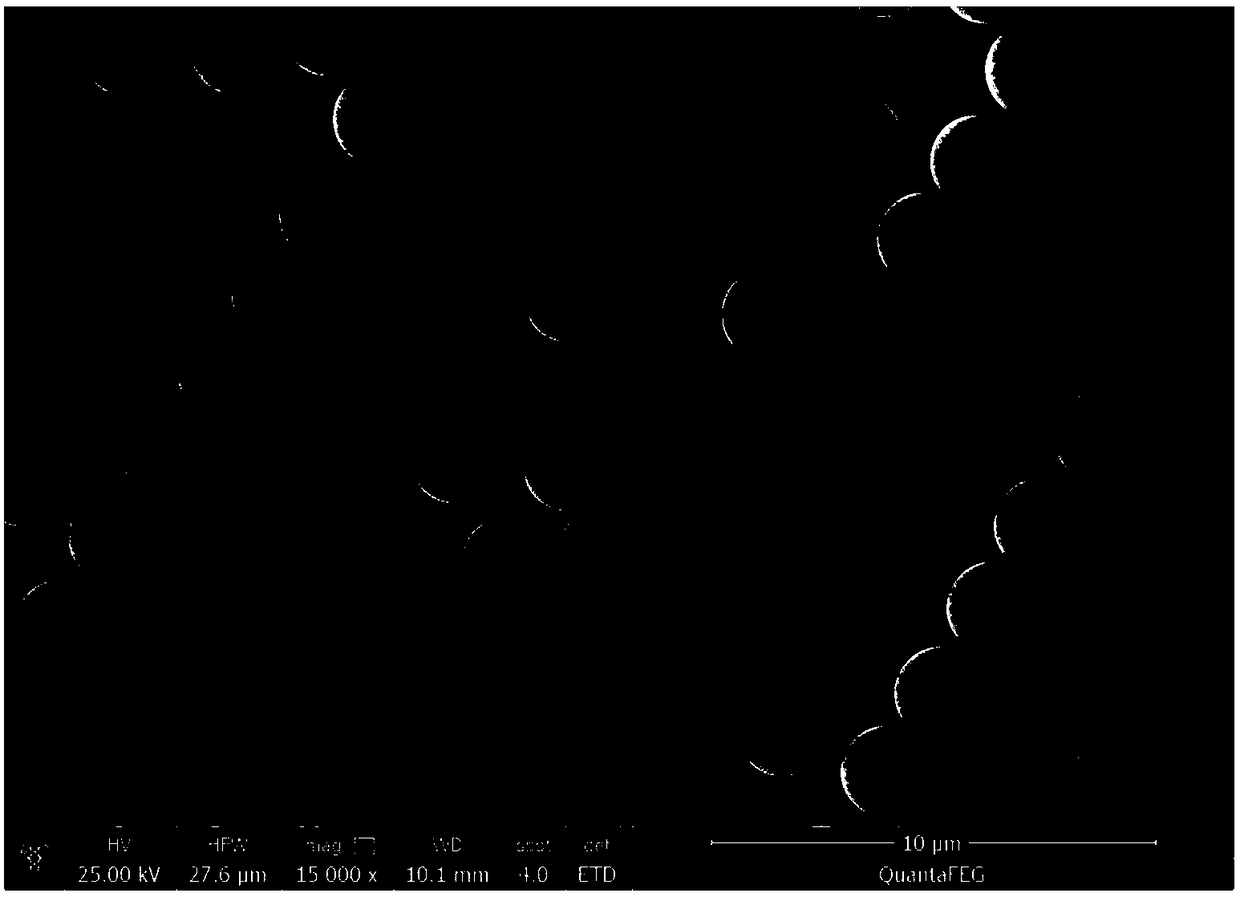

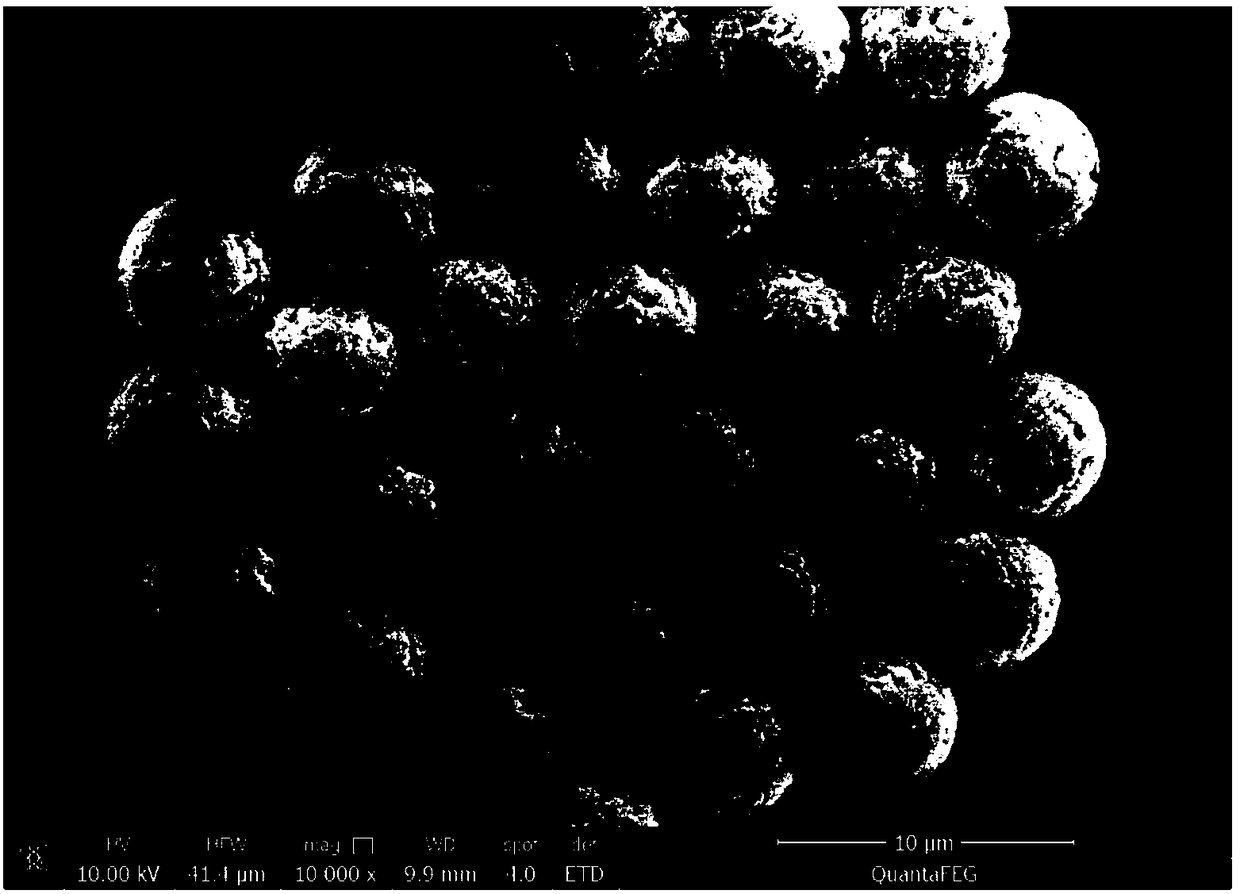

[0026] Weigh 900 g of absolute ethanol, 100 g of pure water, and 10 g of polyvinylpyrrolidone into a 2L four-necked flask equipped with mechanical stirring, and dissolve them by mechanical stirring. 100 g of glycidyl methacrylate monomer was added thereto. The temperature of the water bath was set at 70° C., and when the temperature was raised to 70° C., 100 g of ethanol solution in which 1.2 g of azobisisobutyronitrile was dissolved was quickly added to the reaction system. Mechanical stirring at 200 rpm, water bath at 70°C, and polymerization reaction for 24 hours. The polyglycidyl methacrylate seed microspheres were obtained by centrifugal washing with pure water.

[0027] Weigh 20 g of the seed microspheres prepared above, and disperse them in 1500 g of 0.5% polyvinyl alcohol solution by mass fraction to form dispersion A, which is added to a 2L four-necked flask equipped with mechanical stirring, in a water bath of 35°C, and mechanical stirring at 120 rpm. Weigh 112g of...

Embodiment 2

[0033]Weigh 900 g of absolute ethanol and 10 g of polyvinylpyrrolidone into a 2L four-necked flask equipped with mechanical stirring, and dissolve them by mechanical stirring. 60 g of glycidyl methacrylate monomer was added thereto. The temperature of the water bath was set at 70° C., and when the temperature was raised to 70° C., 100 g of ethanol solution in which 1.2 g of azobisisobutyronitrile was dissolved was quickly added to the reaction system. Mechanical stirring at 200 rpm, water bath at 70°C, and polymerization reaction for 24 hours. The polyglycidyl methacrylate seed microspheres were obtained by ethanol centrifugal washing.

[0034] Weigh 20 g of the seed microspheres prepared above, and disperse them in 1500 g of polyvinyl alcohol solution with a mass fraction of 0.5% to form dispersion A, and place it in a 2L four-necked flask equipped with mechanical stirring, in a water bath of 35°C, and mechanical stirring at 120rpm . Weigh 84g of glycidyl methacrylate, 20g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com