Extraction and application of glowworm grease

A firefly and oil technology, which is applied in the field of oil extraction from fireflies, can solve problems such as undiscovered, and achieve the effects of preventing volatilization, enhancing memory, and enriching unsaturated fatty acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

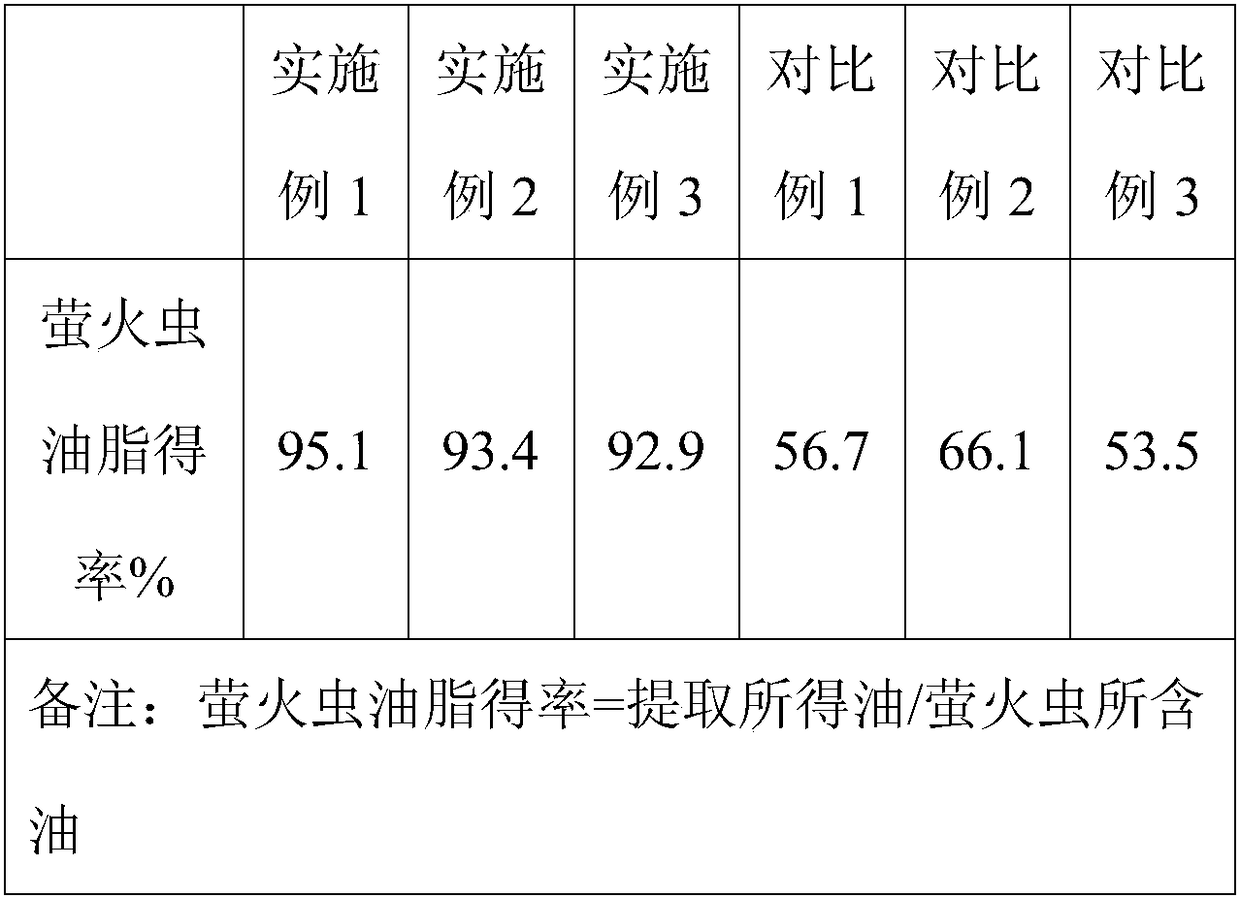

Examples

Embodiment 1

[0026] A method for extracting oil from fireflies, comprising the steps of:

[0027] (1) Fireflies are dried, pulverized into powder, and set aside;

[0028] (2) Preheat the firefly dry powder in step (1) with a microwave device, the microwave frequency is 300w, heat up to 90°C, and heat at a constant temperature until the oil is precipitated, and then adjust the pressure to a negative pressure state. The pressure in the negative pressure state is 80kpa, according to the ratio of material to liquid 1:8, add water to extract for 60min;

[0029] (3) The precipitated oil was left to settle for 18 hours until the oil-water layer was separated and the oil layer was collected;

[0030] (4) Filter the oil layer collected in step (3) with a filter membrane of 0.05 μm, and then conduct microwave heating at 65° C. until the water content is lower than 0.1%, to obtain firefly oil.

Embodiment 2

[0032] A method for extracting oil from fireflies, comprising the steps of:

[0033] (1) Fireflies are dried, pulverized into powder, and set aside;

[0034] (2) Preheat the dry firefly powder in step (1) with a microwave device, the microwave frequency is 100w, raise the temperature to 70°C, and heat at a constant temperature until the oil is precipitated, and then adjust the pressure to a negative pressure state. The pressure in the negative pressure state is 60kpa, according to the ratio of material to liquid 1:5, add water for extraction for 30min;

[0035] (3) The precipitated oil was left to settle for 12 hours until the oil-water layer was separated and the oil layer was collected;

[0036] (4) Filter the oil layer collected in step (3) with a 0.05 μm filter membrane, and then heat it with microwaves at 50° C. until the water content is lower than 0.1%, to obtain firefly oil.

Embodiment 3

[0038] A method for extracting oil from fireflies, comprising the steps of:

[0039] (1) Fireflies are dried, pulverized into powder, and set aside;

[0040] (2) Preheat the firefly dry powder in step (1) with a microwave device, the microwave frequency is 500w, heat up to 110°C, and heat at a constant temperature until the oil is precipitated, and then adjust the pressure to a negative pressure state. The pressure in the negative pressure state is 100kpa, according to the ratio of material to liquid 1:10, add water to extract for 90min;

[0041] (3) The precipitated oil was left to settle for 24 hours until the oil-water layer was separated and the oil layer was collected;

[0042] (4) Filter the oil layer collected in step (3) with a filter membrane of 0.05 μm, and then conduct microwave heating at 80° C. until the water content is lower than 0.1%, to obtain firefly oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com