A composite electrode material for an intelligent supercapacitor and its preparation method and application

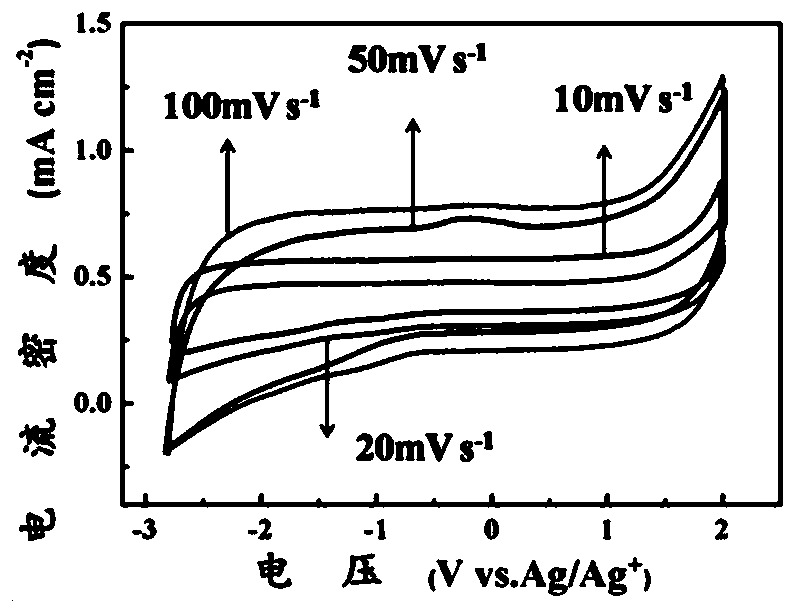

A supercapacitor and composite electrode technology, applied in the field of materials, can solve the problems that the composite cannot be processed in solution, the synthesis method is complicated, and the composite effect is not good, so as to achieve the effect of high energy density, simple composite method, and high cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of alkyl carbazole monomer: 2,7-dibromocarbazole (1 g, 3 mmol) was dissolved in 7.5 mL of DMF, NaH (0.5 g) was added and stirred at room temperature for 30 min. Then 1,8-dibromooctane (4.11 g, 15 mmol) was added dropwise to the above solution, and 2.5 mL of DMF was added to wash the flask wall, and the reaction was carried out at room temperature for 24 h. After the reaction, the mixture was extracted with 100 mL of deionized water to remove NaH, and then the filtrate was rotary evaporated until it reached 5 mL, and then 100 mg of silica gel powder was added and then rotary evaporated to powder again. The crude product was separated and purified through a silica gel column (the eluent is a molar ratio of petroleum ether: dichloromethane = 12:1, first add 100mL petroleum ether to wash away excess 1,8-dibromooctane) to obtain a colorless oily liquid compound , spin-dried by a rotary evaporator, sealed with plastic wrap (perforated) and vacuum-dried to obtain 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com