High-quality dendrobium officinale and varying-temperature differential-pressure puffing drying method thereof

A technology of variable temperature and pressure difference puffing and dendrobium candidum, which is applied in food drying, application, food ingredients, etc., can solve the problems of poor taste, inability to eat directly, and high cost of dendrobium candidum, so as to improve human immunity, good taste, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

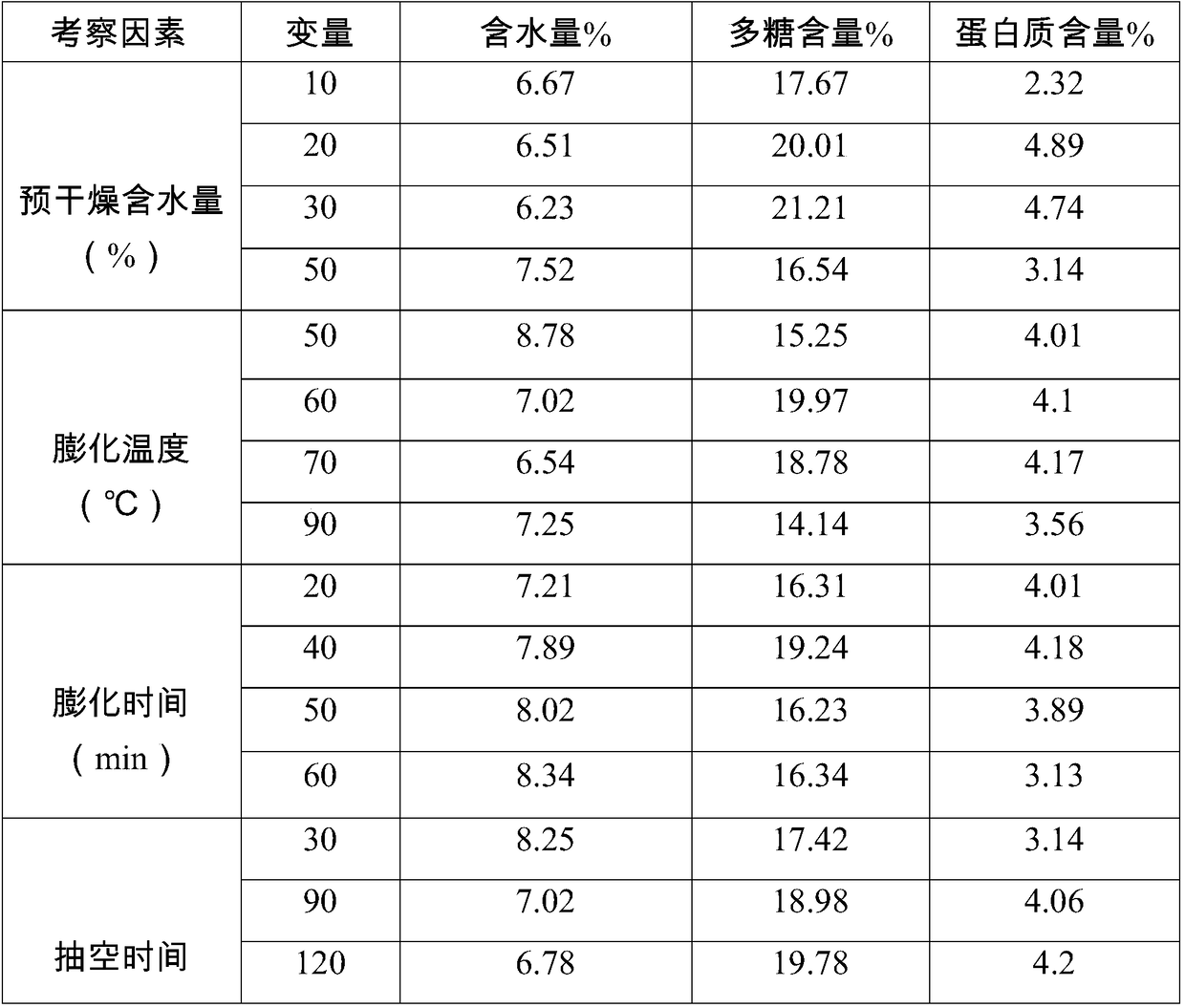

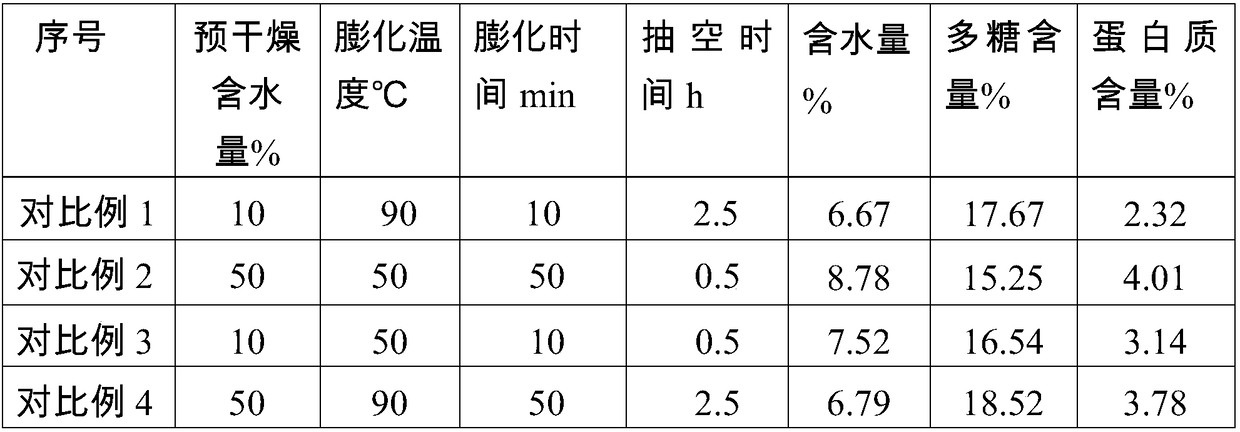

Method used

Image

Examples

Embodiment 1

[0030] 1) raw material selection: select fresh, healthy and clean dendrobium candidum stems as raw materials;

[0031] 2) Raw material pretreatment: cut the stems of Dendrobium officinale in step 1) into 5mm long sections, place them in 10% sucrose aqueous solution for 0.5h soaking at a material-to-liquid ratio of 1:5kg / l, take them out and drain, and set aside.

[0032] 3) Pre-drying of raw materials:

[0033] The pretreated Dendrobium candidum in step 2) was pre-dried in a hot air drying oven at 60° C. to make the water content of Dendrobium candidum 40%, and then put it in a refrigerator at 4° C. to soften for 12 hours and set aside.

[0034] 4) Puffing and drying with variable temperature and pressure difference:

[0035] Put the Dendrobium candidum treated in step 3) into the expansion tank, raise the expansion temperature in the tank to 80°C, raise the air pressure in the tank to 0.1-0.2Mpa, and leave the expansion time for 30min; open the pressure relief valve to make ...

Embodiment 2

[0038] 1) raw material selection: select fresh, healthy and clean dendrobium candidum stems as raw materials;

[0039] 2) Raw material pretreatment: cut the stems of Dendrobium officinale in step 1) into 6mm long pieces, place them in 15% sucrose aqueous solution and soak for 0.8h at a material-to-liquid ratio of 1:4kg / l, take them out and drain, and set aside.

[0040] 3) Pre-drying of raw materials:

[0041] The pretreated Dendrobium candidum in step 2) was pre-dried in a hot air drying oven at 70° C. to make the water content of Dendrobium candidum 30%, and then put it in a refrigerator at 4° C. to soften for 12 hours and set aside.

[0042] 4) Puffing and drying with variable temperature and pressure difference:

[0043] Put the Dendrobium candidum treated in step 3) into an expansion tank, raise the expansion temperature in the tank to 80°C, raise the air pressure in the tank to 0.1-0.2Mpa, and leave the expansion time for 20 minutes; open the pressure relief valve to ma...

Embodiment 3

[0046] 1) raw material selection: select fresh, healthy and clean dendrobium candidum stems as raw materials;

[0047] 2) Raw material pretreatment: cut the stems of Dendrobium officinale in step 1) into 4mm long pieces, place them in 5% sucrose aqueous solution for 1 hour at a material-to-liquid ratio of 1:6kg / l, take them out and drain them, and set aside.

[0048] 3) Pre-drying of raw materials:

[0049] The pretreated Dendrobium candidum in step 2) is pre-dried in a hot air drying oven at 80° C. to make the water content of Dendrobium candidum 20%, and then put it in a refrigerator at 4° C. to soften for 12 hours and set aside.

[0050] 4) Puffing and drying with variable temperature and pressure difference:

[0051] Put the Dendrobium candidum processed in step 3) into an expansion tank, raise the expansion temperature in the tank to 80°C, raise the air pressure in the tank to 0.1-0.2Mpa, and place the expansion time for 40 minutes; open the pressure relief valve to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com