Diethylenetriamine-modified magnetic graphene oxide adsorbent as well as preparation method and application of diethylenetriamine-modified magnetic graphene oxide adsorbent

A technology of ethylenediene triamine and oxidized rock, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve secondary pollution, difficult separation and recovery, and hinder heavy metals Application and other issues, to achieve the effect of improved adsorption performance, high adsorption capacity, and good magnetic separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

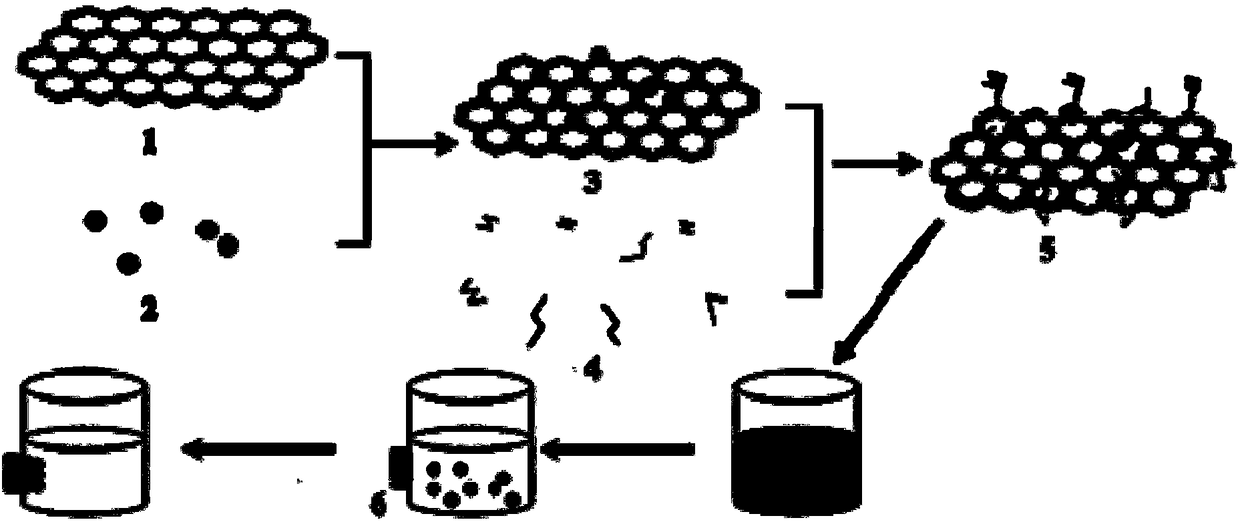

[0037] The preparation of the magnetic graphene oxide adsorbent modified by ethylenediene triamine, concrete steps are as follows:

[0038] (1) 0.3 g GO was gradually added into 100 g deionized water, and then sonicated for 1 hour to obtain solution A;

[0039] (2) Under stirring, FeCl 2 4H 2 O (0.257g) and FeCl 3 ·6H 2 O (0.699g) was dissolved in 100mL of deionized water to obtain mixed solution B;

[0040] (3) Then slowly add solution B to solution A, then add NH dropwise 3 ·H 2 O to adjust the pH to 9, keep the mixed solution at 70°C and keep stirring for 5 hours to obtain the mGO solution;

[0041] (4) The mGO solution obtained in step (3) was added to ethylenedienetriamine (5 mL), stirred continuously at 50 °C for 12 hours, then washed with methanol and deionized water successively, and dried in vacuum at 50 °C for 24 hours, The ethylenedienetriamine-modified magnetic graphene oxide adsorbent (DLTA-mGO) was obtained.

[0042] The prepared ethylenedienetriamine-modif...

Embodiment 2

[0044] The preparation of the magnetic graphene oxide modified by ethylenediene triamine, concrete steps are as follows:

[0045] (1) 0.4 g GO was gradually added into 150 g deionized water, and then sonicated for 1 hour to obtain solution A;

[0046] (2) Under stirring, FeCl 2 4H 2 O (0.257g) and FeCl 3 ·6H 2 O (0.699g) was dissolved in 100mL of deionized water to obtain mixed solution B;

[0047] (3) Then slowly add solution B to solution A, then add NH dropwise 3 ·H 2 O to adjust the pH to 10, keep the mixed solution at 80°C and keep stirring for 4 hours to obtain the mGO solution;

[0048] (4) The mGO solution obtained in step (3) was added to ethylenedienetriamine (8 mL), stirred continuously at 60 °C for 8 hours, then washed with methanol and deionized water successively, and dried in vacuum at 50 °C for 24 hours. The ethylenedienetriamine-modified magnetic graphene oxide adsorbent (DLTA-mGO) was obtained.

[0049] Adsorb the prepared ethylenedienetriamine-modifi...

Embodiment 3

[0051] The preparation of the magnetic graphene oxide modified by ethylenediene triamine, concrete steps are as follows:

[0052] (1) Add 0.5 g GO gradually to 200 g deionized water, and then sonicate for 1 hour to obtain solution A;

[0053] (2) Under stirring, FeCl 2 4H 2 O (0.257g) and FeCl 3 ·6H 2 O (0.699g) was dissolved in 100mL of deionized water to obtain mixed solution B;

[0054] (3) Then slowly add solution B to solution A, then add NH dropwise 3 ·H 2 O to adjust the pH to 11, keep the mixed solution at 90°C and keep stirring for 3 hours to obtain the mGO solution;

[0055] (4) The mGO solution obtained in step (3) was added to ethylenedienetriamine (10 mL), stirred continuously at 70 °C for 6 hours, then washed with methanol and deionized water successively, and dried in vacuum at 50 °C for 24 hours, The ethylenedienetriamine-modified magnetic graphene oxide adsorbent (DLTA-mGO) was obtained.

[0056] TEM image of unmodified graphene oxide Figure 2a As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com