Super absorbent resin and preparation method thereof

A technology of super absorbent resin and auxiliary agent, applied in the field of super absorbent resin and its preparation, can solve the problems of insufficient antibacterial and heat resistance properties of super absorbent resin, achieve high efficiency of antibacterial and heat resistance, improve efficiency and biocompatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

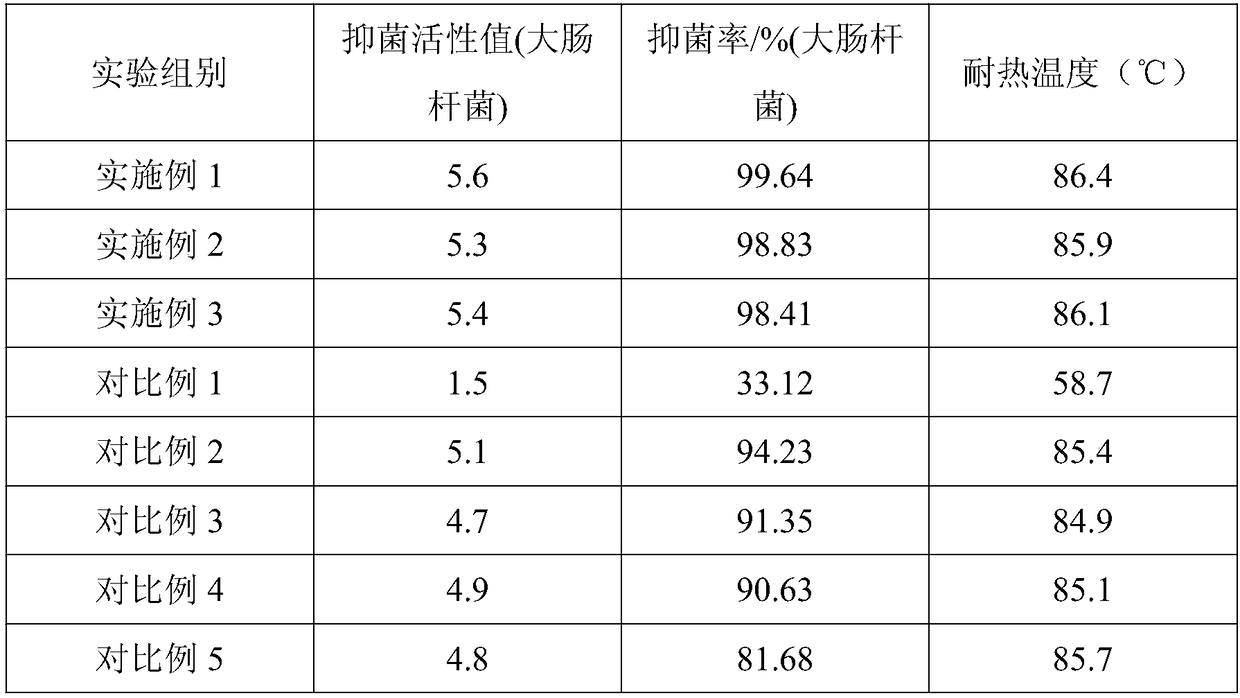

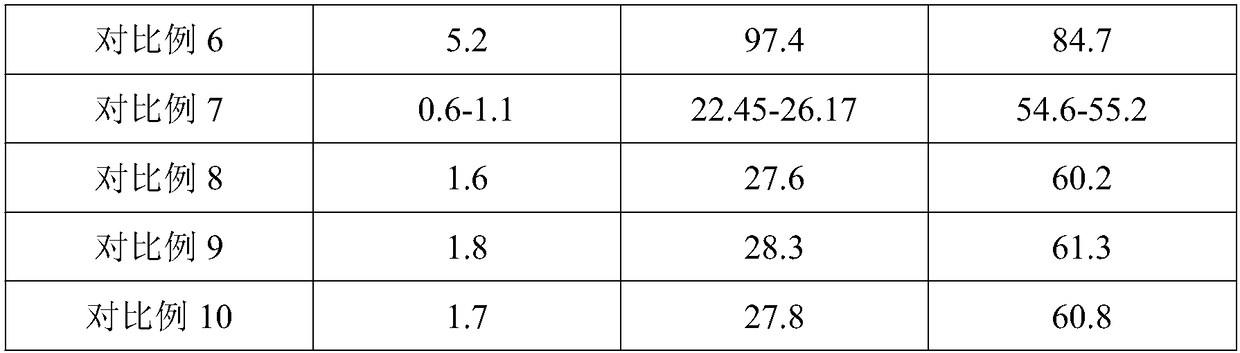

Examples

preparation example Construction

[0031] The preparation method of described superabsorbent resin, comprises the following steps:

[0032] S1. Mix methacrylate, inorganic alkali solution, acrylamide, 2-methylbenzenesulfonic acid, baking soda and ammonia water evenly, stir at 4000-6000r / min for 10-15min, then add xanthan gum and mix evenly. Heat up to 80-90°C, keep warm for 1-2h, stir at 650-850r / min for 1-2h, cool to room temperature to obtain the base material;

[0033] S2. After mixing polylactic acid, chitosan and silane coupling agent KH-570, heat up to 50-60°C, keep warm for 1-3h, keep stirring during the heat preservation process, and then add antibacterial modification additives and heat-resistant Mix the modified additives evenly, continue to heat up to 70-80°C, stir and disperse at 300-350r / min for 5-15min to obtain modified fillers;

[0034] S3. In a closed mixer, mix the base material and the modified filler evenly, heat up to 80-90°C, keep warm for 1-3h, then stir at 1500-2500r / min for 1-2h, cool ...

Embodiment 1

[0037] A superabsorbent resin, in parts by weight, comprising the following raw materials: 189 parts of methacrylate, 305 parts of inorganic alkali solution, 89 parts of acrylamide, 64 parts of 2-methylbenzenesulfonic acid, 5.4 parts of xanthan gum, 1.7 parts of baking soda, 38.6 parts of ammonia water, 14.6 parts of polylactic acid, 8.5 parts of chitosan, 23.5 parts of antibacterial modified additives, 14.9 parts of heat-resistant modified additives, and 2.6 parts of silane coupling agent KH-570.

[0038] The antibacterial modified auxiliary agent is prepared according to the following process: 8.4 parts of seaweed powder, 5.7 parts of natural zeolite and 4.8 parts of sodium chloride solution with a mass fraction of 13.4% are mixed uniformly by weight, stirred for 2.8 hours, filtered and dehydrated, and dried. Then roasted at 496.6°C for 0.9h, then placed in 6.8 parts of lanthanum chloride solution with a mass fraction of 28%, stirred for 2.3h, filtered and dehydrated, dried, ...

Embodiment 2

[0045] A superabsorbent resin, in parts by weight, comprising the following raw materials: 100 parts of methacrylate, 320 parts of inorganic alkali solution, 30 parts of acrylamide, 80 parts of 2-methylbenzenesulfonic acid, 2 parts of xanthan gum, 2 parts of baking soda, 25 parts of ammonia water, 15 parts of polylactic acid, 6 parts of chitosan, 24 parts of antibacterial modification additives, 10 parts of heat-resistant modification additives, 3 parts of silane coupling agent KH-5703.

[0046]The antibacterial modified auxiliary agent is prepared according to the following process: 6 parts of seaweed powder, 8 parts of natural zeolite and 2 parts of sodium chloride solution with a mass fraction of 15% are mixed uniformly by weight, stirred for 1 hour, filtered and dehydrated, dried, and then Calcined at 550°C for 0.5h, then placed in 7 parts of lanthanum chloride solution with a mass fraction of 15%, stirred for 3h, filtered and dehydrated, dried, then placed at 180°C for 1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com