Production and purification method of glucose dehydrogenase by taking FAD (Flavin Adenine Dinucleotide) as prothetic group

A glucose dehydrogenase, FAD-GDH technology, applied in the field of purification and glucose dehydrogenase production, can solve the problems of protein purification and scale-up production difficulties, and achieve good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The construction of embodiment 1 genetically engineered bacteria

[0057] (1) The obtained FAD-GDH gene SEQ ID NO: 1 is connected with the plasmid pTrc99A to obtain the expression vector pTrc99A-GDH;

[0058] (2) Transforming the recombinant vector pTrc99A-GDH into Escherichia coli BL21(DE3) to obtain the Escherichia coli recombinant bacteria.

Embodiment 2

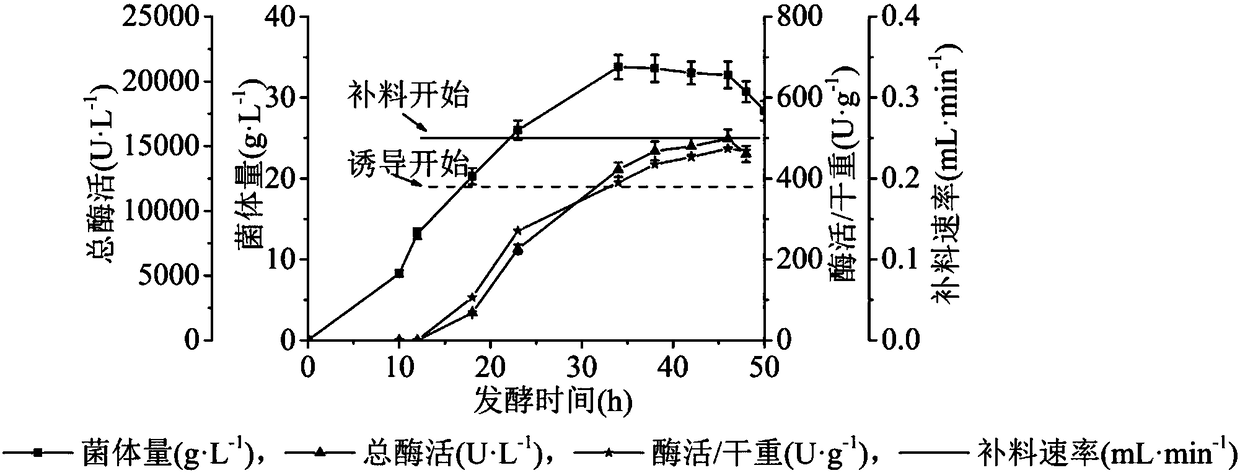

[0059] Example 2 Effect of 7.5L fermenter with constant flow and feeding medium on the production of glucose dehydrogenase by fermentation

[0060] The method for producing glucose dehydrogenase by recombinant Escherichia coli fermentation tank fermentation is carried out in a 7.5L tank, and the process is divided into three stages:

[0061] The first stage: Inoculate single colonies of recombinant E. coli in Example 3 into a 150mL Erlenmeyer flask equipped with 30mL LB medium, 200rpm, 37°C shaking culture for 8h, as a primary seed fermentation liquid;

[0062] The second stage: take 15 mL of the primary seed fermentation liquid and inoculate it in a 500 mL Erlenmeyer flask equipped with 300 mL of fermentation medium, 200 rpm, shake at 37°C for 8 hours, and use it as the secondary seed fermentation liquid;

[0063] The third stage: put the activated seed liquid into the fermenter in batches by 10% by volume, and when the DO value rises rapidly, the dissolved oxygen rises rapid...

Embodiment 3

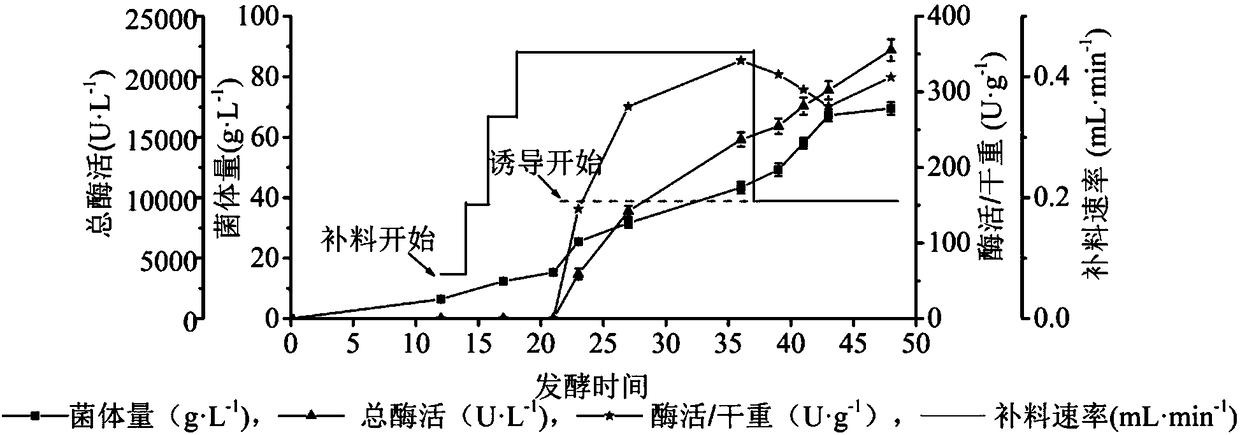

[0065] Example 3 Effect of 7.5L fermenter with constant flow and feeding medium on the production of glucose dehydrogenase by fermentation

[0066] The method for producing glucose dehydrogenase by recombinant Escherichia coli fermentation tank fermentation is carried out in a 7.5L tank, and the process is divided into three stages:

[0067] The first stage: Inoculate single colonies of recombinant E. coli in Example 3 into a 150mL Erlenmeyer flask equipped with 30mL LB medium, 200rpm, 37°C shaking culture for 8h, as a primary seed fermentation liquid;

[0068] The second stage: take 15 mL of the primary seed fermentation liquid and inoculate it in a 500 mL Erlenmeyer flask equipped with 300 mL of fermentation medium, 200 rpm, shake at 37°C for 8 hours, and use it as the secondary seed fermentation liquid;

[0069] The third stage: put the activated seed liquid into the fermenter in batches according to the volume fraction of 10%. When the DO value rises rapidly, the dissolved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com