Multi-temperature-range composite halide ammonia storage tank structure with temperature range self-adaption function

An adaptive, ammonia storage tank technology, applied in the direction of mufflers, exhaust treatment, engine components, etc., can solve problems that do not involve the analysis of the adaptability of working conditions, so as to improve the utilization rate of residual energy, increase the release rate, increase The effect of ammonia storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

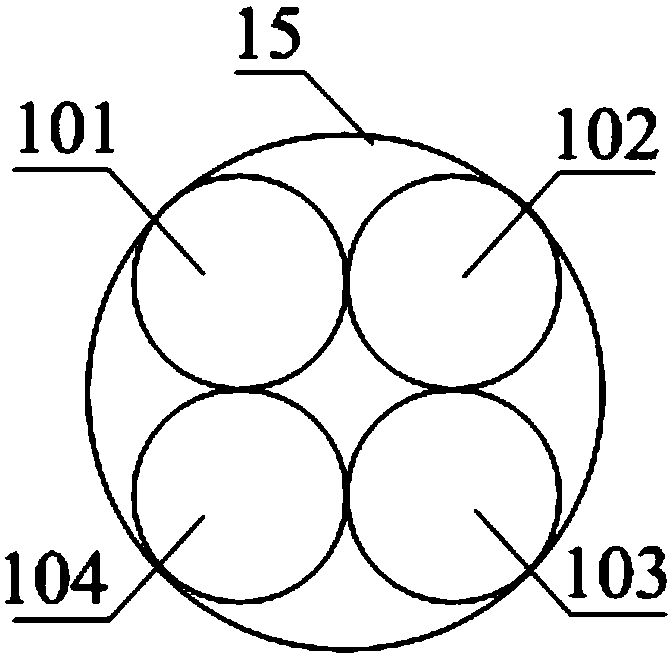

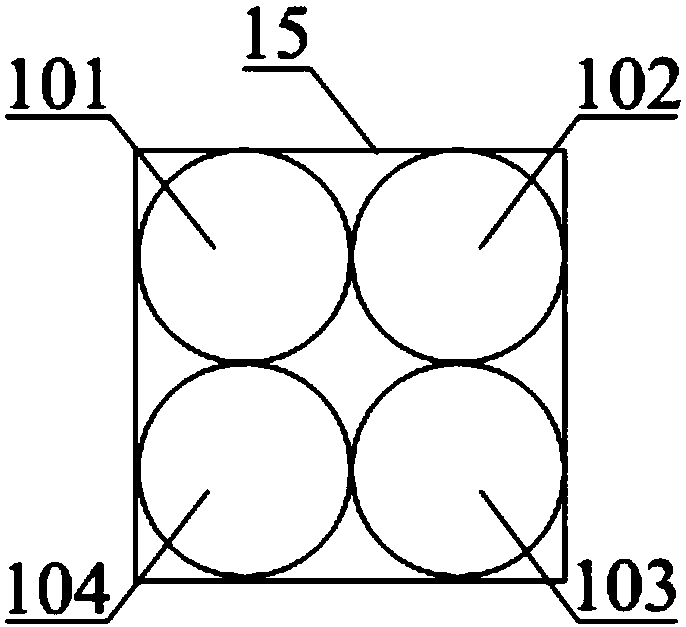

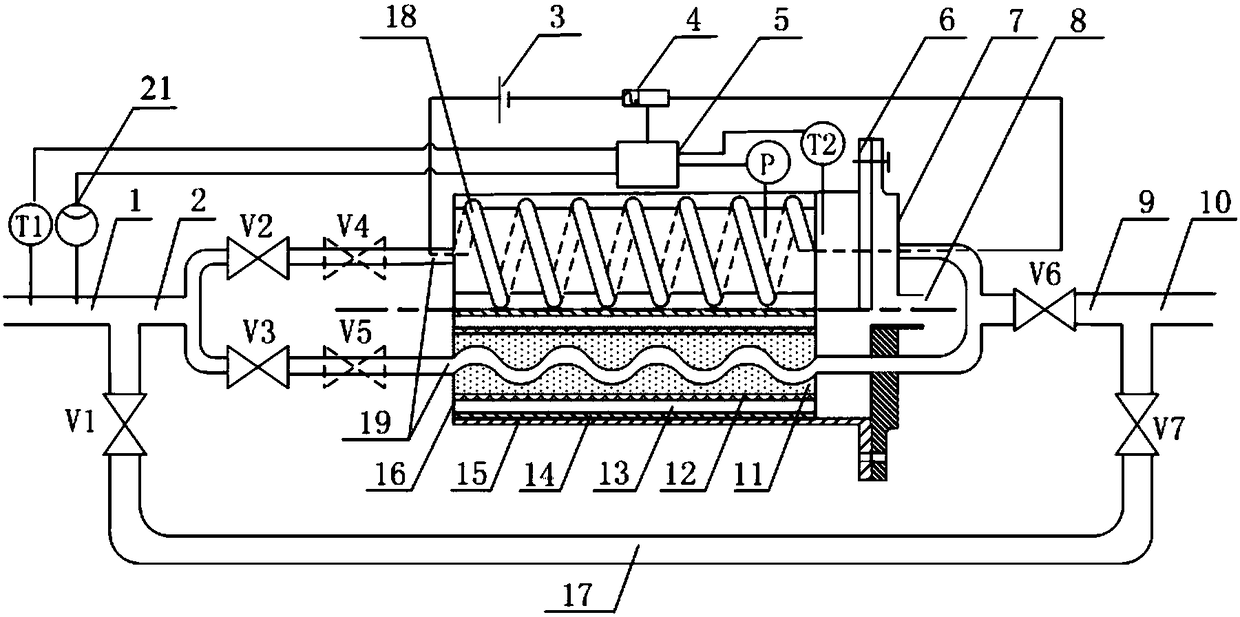

[0060] Such as image 3 As shown, the plurality of unit tubes include a first unit tube 101 , a second unit tube 102 , a third unit tube 103 and a fourth unit tube 104 . The first unit pipe 101, the second unit pipe 102, the third unit pipe 103, and the fourth unit pipe 104 are respectively provided with a first flue gas branch pipe, a second flue gas branch pipe, and a third flue gas branch pipe. pipe, the fourth flue gas branch pipe; the first flue gas branch pipe, the second flue gas branch pipe, the third flue gas branch pipe, and the fourth flue gas branch pipe are respectively provided with valve V2 and valve V3 , valve V4, valve V5; among the two ends of the flue gas safety pipe 17 along the length direction, one end close to the flue gas inlet pipe 1 and one end close to the flue gas outlet pipe 10 are respectively provided with a valve V1 and a valve V7; the downstream of the main flue gas pipe Section 9 is provided with a valve V6. The heating belt 18 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com