A kind of hydrogel, oil-water separator and its preparation method and application

An oil-water separator and oil-water separation technology, which are applied in separation methods, liquid separation, grease/oily substance/floating matter removal devices, etc., can solve the problems of irreparability, repeated use, high swelling rate, and low cost. , long life, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1: P(AM-co-AA) / CS / MPS-SiO with different proportions of AA and AM 2 / Preparation of semi-interpenetrating hydrogels and simple oil-water separators.

[0067] Weigh different proportions of acrylamide and acrylic acid, dissolve them in a certain volume of deionized water and add them to a 50ml round bottom flask, then add a certain amount of double bond modified silica nanoparticles and fully disperse them under ultrasonic conditions. A transparent mixture A (a suspension) was obtained.

[0068] Then measure a certain amount of chitosan and add it therein, and after adjusting its pH to be acidic, stir ultrasonically to dissolve all the chitosan to obtain a viscous mixed solution B.

[0069] After passing nitrogen gas under magnetic stirring, add an initiator (a thermal initiator such as ammonium persulfate) and a catalyst to obtain a mixed solution C.

[0070] Seal the mixed solution C in a transparent mold and place it under sunlight for one day to obtain fiv...

Embodiment 2

[0072] Example 2: In this example, to investigate the mechanical properties of various hydrogels prepared by the present invention, the inventor prepared hydrogels as test specimens for testing tensile stress and strain. The test process is as follows:

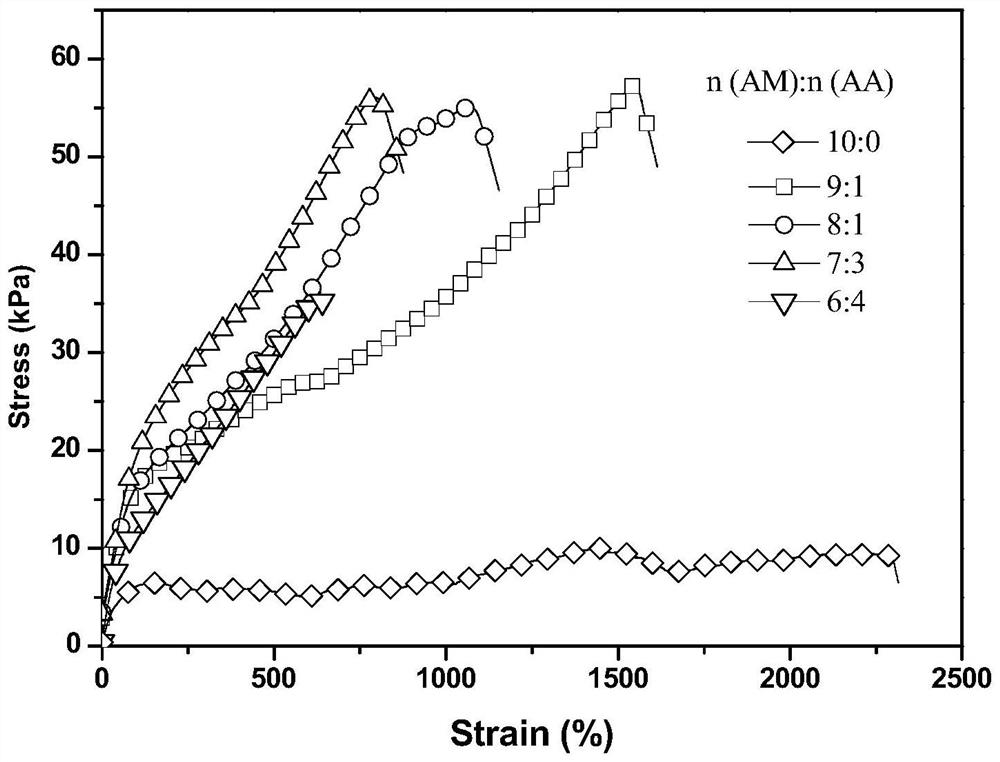

[0073] P(AM-co-AA) / CS / MPS-SiO of different proportions AM and AA obtained from Example 1 2 Semi-interpenetrating composite hydrogels. The obtained hydrogel was prepared as 10mm in diameter and 5 specimens with a height of 20mm at room temperature at a stretching rate of 30mm / min, and a tension machine was used to measure the tensile stress and strain of the prepared hydrogel. The result is as figure 1 shown. It can be seen that P(AM-co-AA) / CS / MPS-SiO when AM:AA is 9:1 2 The semi-interpenetrating composite hydrogel has the most superior tensile properties.

Embodiment 3

[0074]Example 3: In order to investigate the mechanical properties of various hydrogels prepared by the present invention, the inventors prepared the hydrogels as test specimens for the test of compressive stress and strain. The test process is as follows:

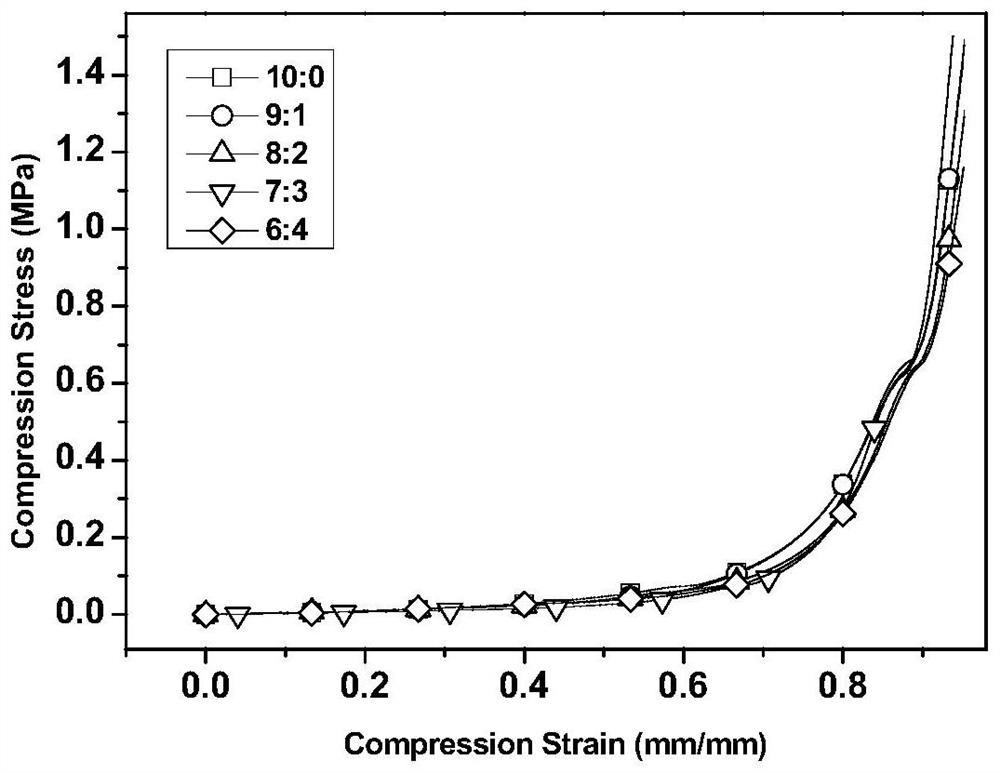

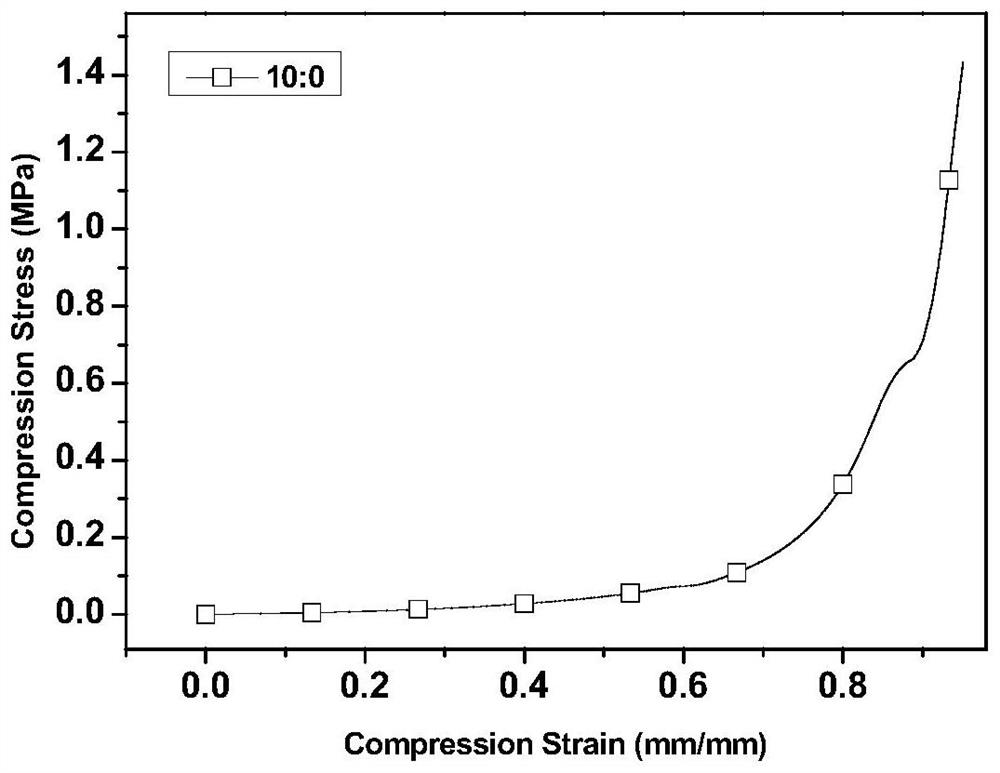

[0075] The hydrogel obtained in Example 1 is prepared as a diameter of 10mm, and each 5 specimens of high 10mm are at room temperature with a stretching rate of 5mm / min, and the compressive stress strain of the prepared hydrogel is measured with a universal tensile machine . P(AM-co-AA) / CS / MPS-SiO of different proportions AM and AA obtained from Example 1 2 The semi-interpenetrating composite hydrogel was tested for tensile stress and strain, and the results are as follows Figure 2 to Figure 7 shown. It can be seen that P(AM-co-AA) / CS / MPS-SiO when AM:AA is 9:1 2 Semi-interpenetrating composite hydrogels have the most superior compressive properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile stress | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| tensile strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com