Coal gasification-gas base shaft furnace direct reduction system and technology

A gas-based shaft furnace and coal-to-gas technology, applied in shaft furnaces, combustible gas manufacturing, furnaces, etc., to achieve the effects of long life of furnace tubes, simple equipment, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

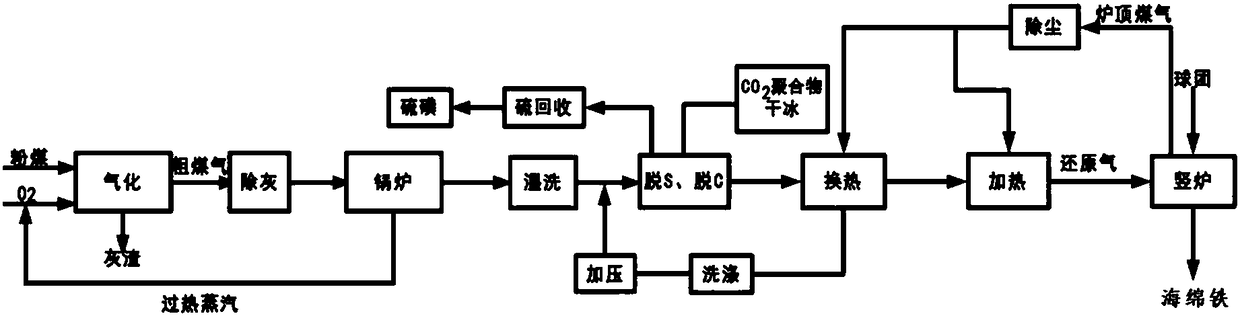

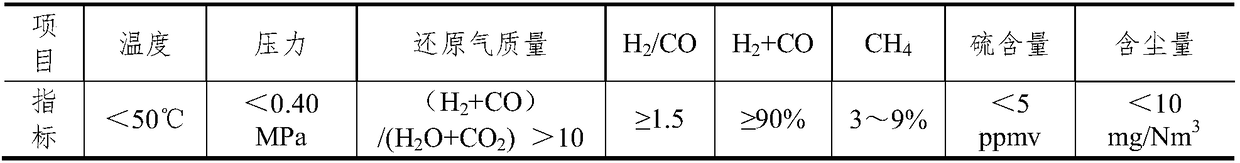

[0042] refer to figure 1 , this embodiment provides a coal-based gas-based shaft furnace direct reduction system, including a coal-based reducing gas system and a gas-based shaft furnace direct reduction system, wherein the coal-based reducing gas system includes a gas production unit, ash removal and wet cleaning unit , purification unit and heat exchange unit, the gas-based shaft furnace direct reduction system includes a reducing gas heating unit and a gas-based shaft furnace unit.

[0043] Specifically, the gas production unit is used to make pulverized coal into a gas rich in carbon monoxide (CO) and hydrogen (H 2 ) of crude gas, the ash removal and wet cleaning unit is used for deashing and wet cleaning of the crude gas, and the purification unit is used for desulfurization and decarbonization of the crude gas output from the ash removal and wet cleaning unit to obtain clean gas. The heat exchange unit is used to exchange heat between the clean coal gas and the top gas ...

Embodiment 2

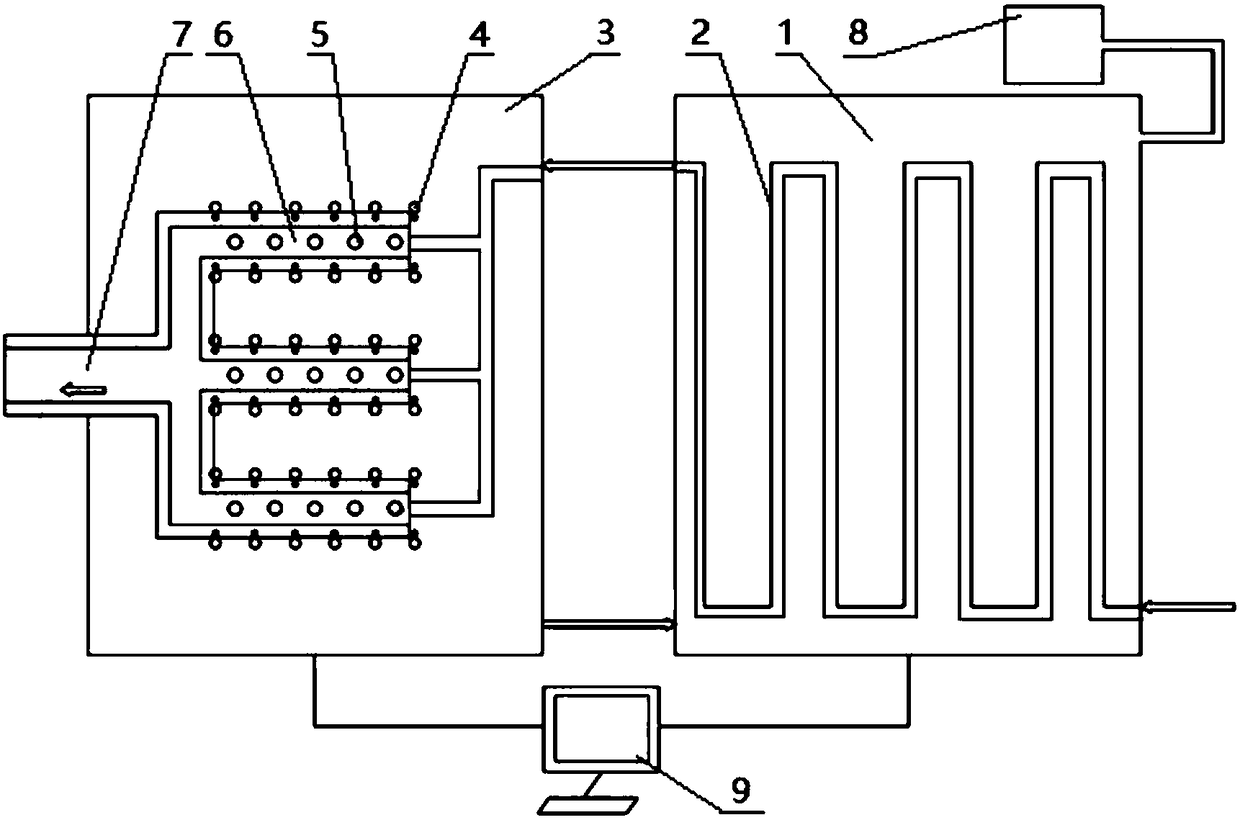

[0082] This embodiment mainly provides the detailed structure of the reducing gas heating unit mentioned in the above embodiment 1, including the preheating furnace 1 and the heating furnace 3, specifically as follows:

[0083] refer to figure 2 A preheating furnace tube 2 is arranged in the preheating furnace 1, and the two ends of the preheating furnace tube 2 pass through the preheating furnace 1 respectively. The part of the preheating furnace tube 2 in the preheating furnace 1 is a zigzag long tube. The space outside the preheating furnace tube 2 in the preheating furnace 1 is the preheating working space.

[0084] The heating furnace 3 is provided with an array of heating furnace tubes 5, figure 2 The middle heating furnace tubes 5 are vertically arranged in three rows and five rows, parallel to each other, and can also be arranged in shapes such as concentric rings. The heating furnace tube 5 is made of a high temperature resistant alloy, so that the heating furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com