Internal combustion engine and gardening tool with same

An internal combustion engine, small technology, applied in gardening tools/equipment, cutting tools, engine lubrication, etc., can solve the problems of poor structural stability, difficult structural layout, difficult mold manufacturing, etc., to achieve simple structure, reduced processing difficulty, reduced effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

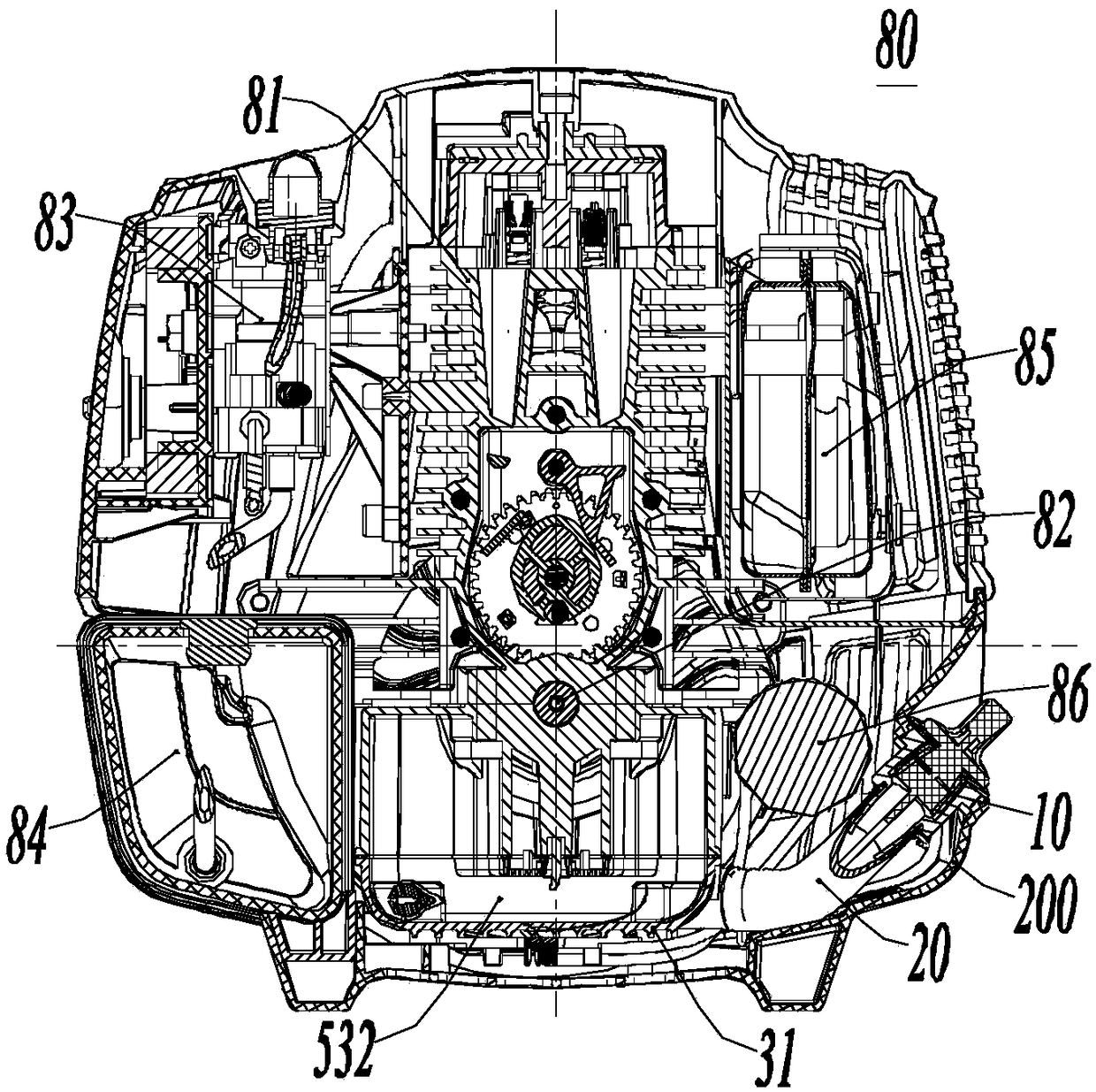

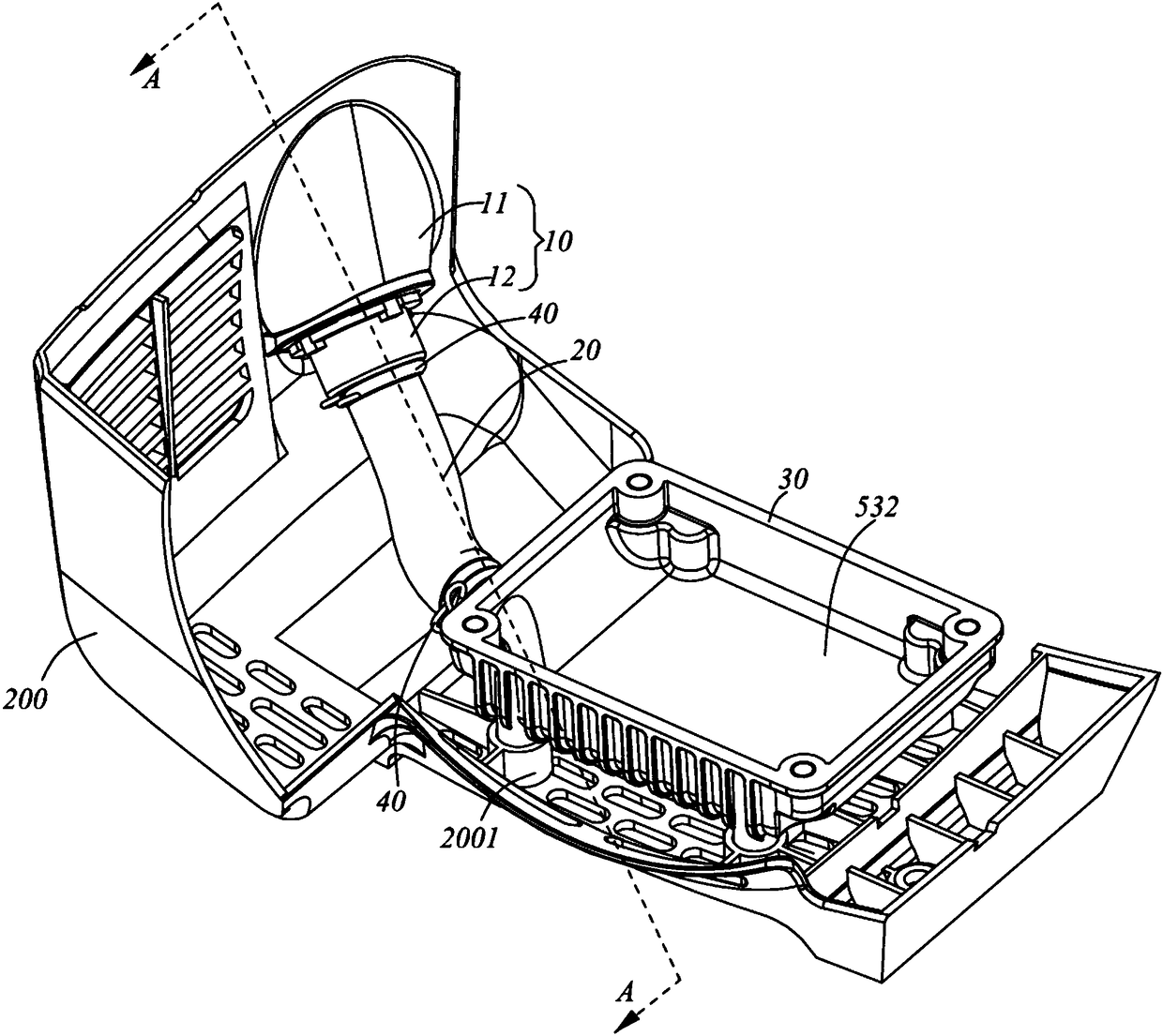

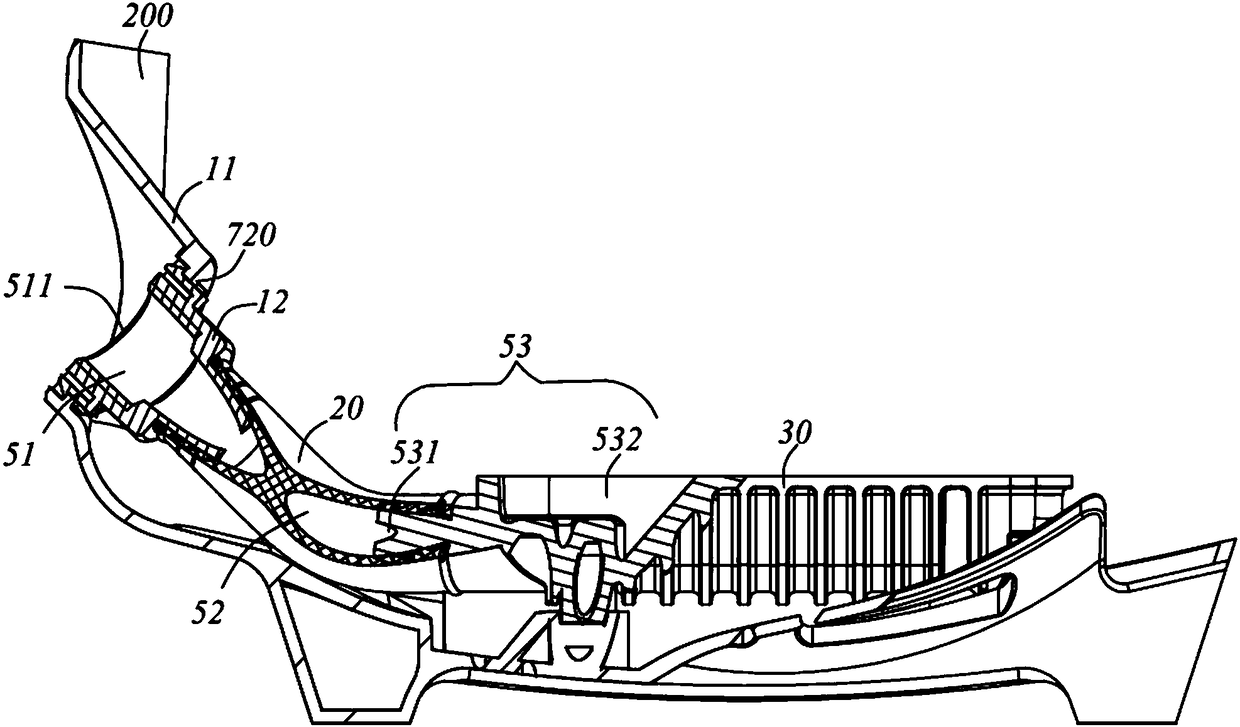

[0034] Such as figure 1 and figure 2 As shown, an embodiment of the present invention discloses a small internal combustion engine, especially a small gasoline engine 80. The gasoline engine 80 includes a casing 200 and an internal combustion engine body disposed in the casing 200, wherein the internal combustion engine body It includes a cylinder 81, a crankcase disposed below the cylinder 81, a piston disposed in the cylinder 81 and reciprocating, a crankshaft 82 disposed in the crankcase and driving the piston, and a storage disposed below the crankcase The oil pan 30 for lubricating oil. The oil pan 30 has an oil pan oil inlet, and the housing 200 has a housing oil inlet; the internal combustion engine body also includes a hose 20 connecting the oil pan oil inlet and the The oil inlet of the housing forms a fluid channel for lubricating oil to flow from the oil inlet of the housing to the oil pan 30.

[0035] In this example, press figure 1 In the orientation shown, the cyli...

Embodiment 2

[0071] See Figure 13 , Another embodiment of the present invention, this embodiment discloses a garden tool, the garden tool can be specifically set as a lawn mower, lawn mower, brush cutter, pruning machine, chain saw, etc., in this embodiment Among them, the garden tool is a lawn mower 90, which includes a head 91, a connecting rod 92, a handle 93 and a lawn mower 94. Among them, the machine head 91 is connected to one end of the connecting rod 92, and the cutting head 94 is connected to the other end of the connecting rod 92. The handle 93 is connected to the middle of the connecting rod 92, and the connecting position and angle of the handle 93 can be adjusted according to user requirements. The lawn mower 90 uses a small internal combustion engine as a power source. Specifically, a small gasoline engine 80 is provided in the nose 91. The connecting rod 92 is provided with a power transmission assembly through which the small gasoline engine 80 drives the mowing rope of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com