Preparation method of nickelic ternary lithium battery cathode material with low mixing

A technology for ternary lithium batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as high temperature instability, capacity attenuation, and poor practical effects, and achieve the solution of nickel-lithium mixed discharge Severe, inhibit mixed discharge, improve the effect of the first charge and discharge capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

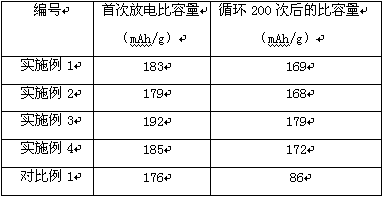

Examples

Embodiment 1

[0026] S01: Nickel chloride, cobalt chloride, and manganese chloride are weighed according to the molar ratio of nickel, cobalt, and manganese 8:1:1, and prepared into salt solution respectively;

[0027] S02: Slowly add nickel chloride solution to the mixed solution prepared by strong oxidizing hydrogen peroxide and sodium hydroxide solution, adjust the pH to 9 to form nickel oxyhydroxide; then add cobalt chloride and manganese chloride, and add precipitate at the same time Sodium hydroxide;

[0028] S03: Heating in a water bath at 40-50°C while using ultrasonic dispersion to react cobalt and manganese metal ions into the nickel oxyhydroxide interlayer by intercalation to obtain a gel-like precipitate;

[0029] S04: Filter the gel obtained in step S03 through a reverse osmosis membrane, the pore size only allows water molecules to pass through, and then mix nickel with lithium chloride and magnesium chloride in a molar ratio of 3:1:1, when the oxygen content is 50% The sinte...

Embodiment 2

[0031] S01: Nickel chloride, cobalt chloride, and manganese chloride are weighed according to the molar ratio of nickel, cobalt, and manganese 8:1:1, and prepared into salt solution respectively;

[0032] S02: Slowly add nickel chloride solution to the mixed solution prepared by strong oxidizing potassium permanganate and sodium hydroxide solution, adjust the pH to 10 to form nickel oxyhydroxide; then add cobalt chloride and manganese chloride, and add Precipitating agent sodium hydroxide;

[0033]S03: Heating in a water bath at 40-50°C while using ultrasonic dispersion to react cobalt and manganese metal ions into the nickel oxyhydroxide interlayer by intercalation to obtain a gel-like precipitate;

[0034] S04: Filter the gel obtained in step S03 through a reverse osmosis membrane, the pore size only allows water molecules to pass through, and then mix nickel with lithium chloride and magnesium chloride in a molar ratio of 3:1:1, when the oxygen content is 65% The sintering...

Embodiment 3

[0036] S01: Nickel chloride, cobalt chloride, and manganese chloride are weighed according to the molar ratio of nickel, cobalt, and manganese 8:1:1, and prepared into salt solution respectively;

[0037] S02: Slowly add nickel chloride solution to the mixed solution prepared by strong oxidizing hydrogen peroxide and sodium hydroxide solution, adjust the pH to 12 to form nickel oxyhydroxide; then add cobalt chloride and manganese chloride, and add precipitate at the same time Sodium hydroxide;

[0038] S03: Heating in a water bath at 40-50°C while using ultrasonic dispersion to react cobalt and manganese metal ions into the nickel oxyhydroxide interlayer by intercalation to obtain a gel-like precipitate;

[0039] S04: Filter the gel obtained in step S03 through a reverse osmosis membrane, the pore size only allows water molecules to pass through, and then mix nickel with lithium chloride and magnesium chloride in a molar ratio of 3:1:1, when the oxygen content is 65% The sint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com